Mixer

A mixer and reducer technology, applied in the field of chemical machinery, can solve the problems of material drop, uneven mixing, and the helical piece cannot fully contact the material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

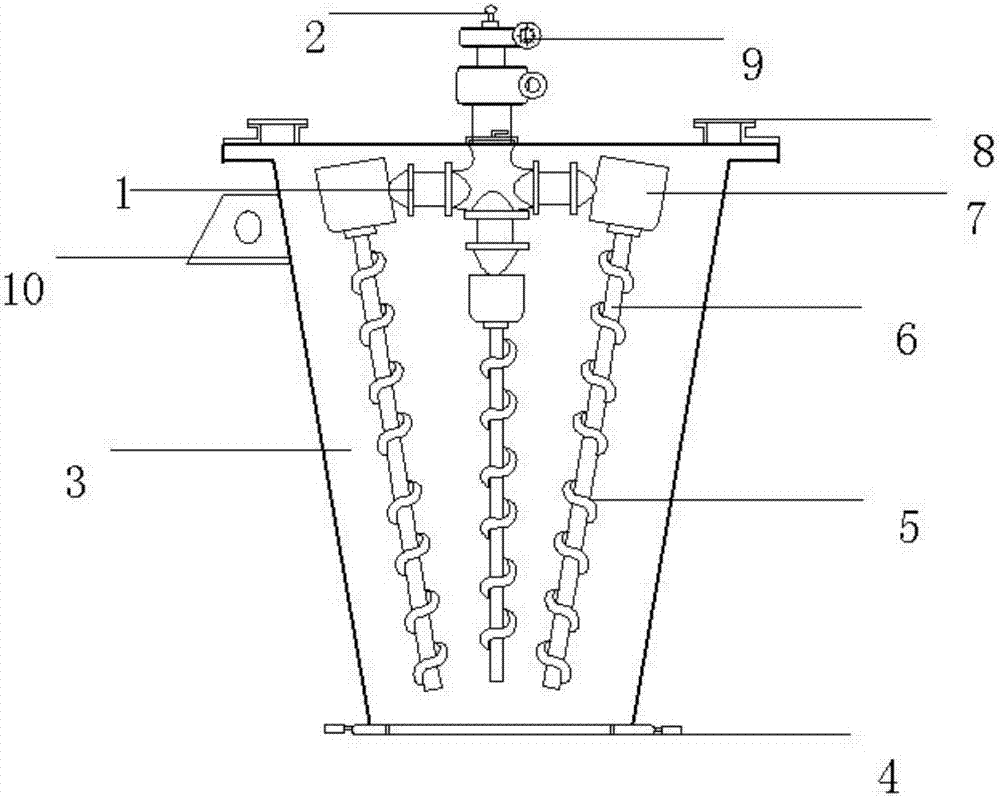

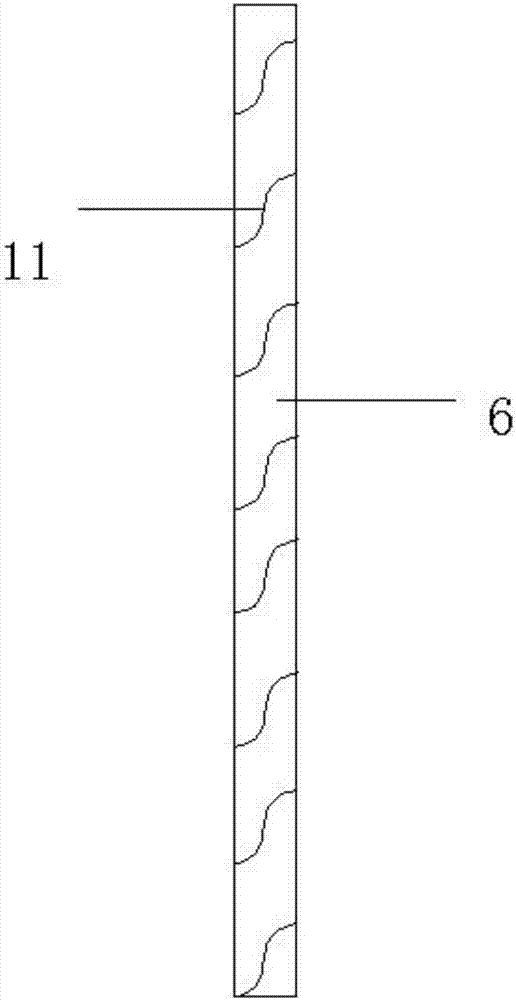

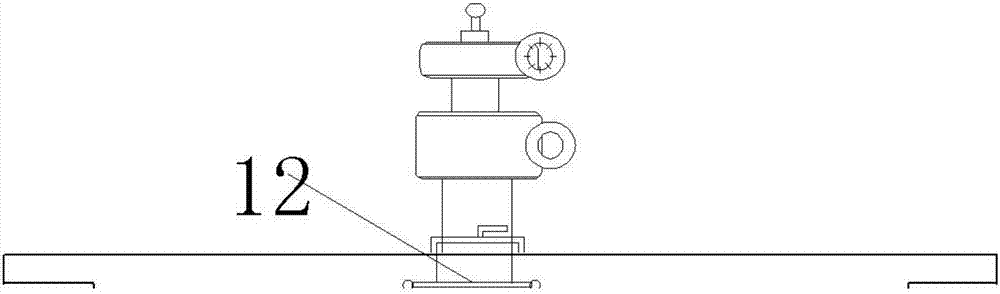

[0018] A mixer, characterized in that its structure includes a cylinder 3, a discharge valve 4, a screw blade 5, a rotating head 7, a rotating arm 1 and a reducer 9, and the cylinder 3 is connected to the rotating arm 1 , the rotating arm 1 is connected to the rotating head 7, the rotating head 7 is connected to the telescopic rotating shaft 6, the telescopic rotating shaft 6 is connected to the spiral blade 5, and the cylinder body 3 is connected to the liquid injection port 12 , the cylinder body 3 is connected with two feeding ports 8 and the reducer 9 , and the reducer 9 is connected with the liquid-feeding joint 2 . The surface of the telescopic rotating shaft 6 is provided with a card groove piece 11, the cylinder body 3 is connected with a switch button 11, the rotating head 7 is fixed to the telescopic rotating shaft 6 by screws, and the rotating arm 1 and the rotating head 7 joints are provided with grooves. The three-helix stirring device of the present invention ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com