Endoscope transmission mechanism and endoscope with transmission mechanism

A transmission mechanism and endoscope technology, applied in the field of endoscopes, can solve the problems of difficulty in ensuring welding quality, low production efficiency, and long overall length, avoiding acid mist vapor pollution, easy adjustment and maintenance, and easy assembly. and the effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

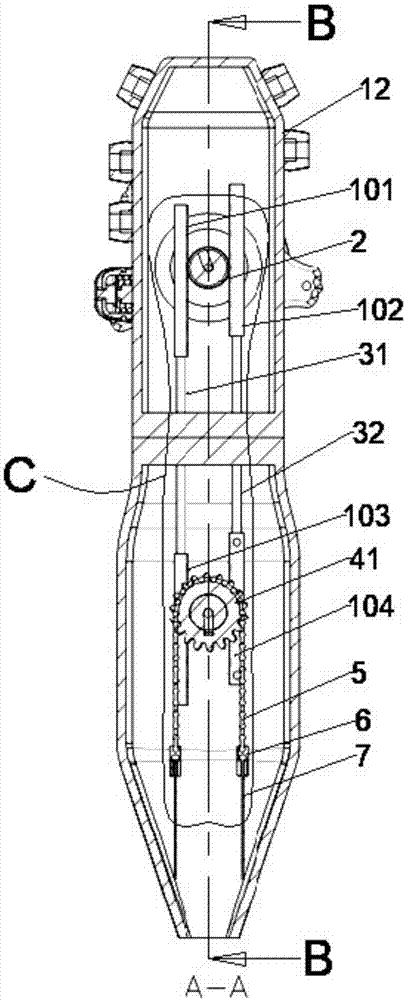

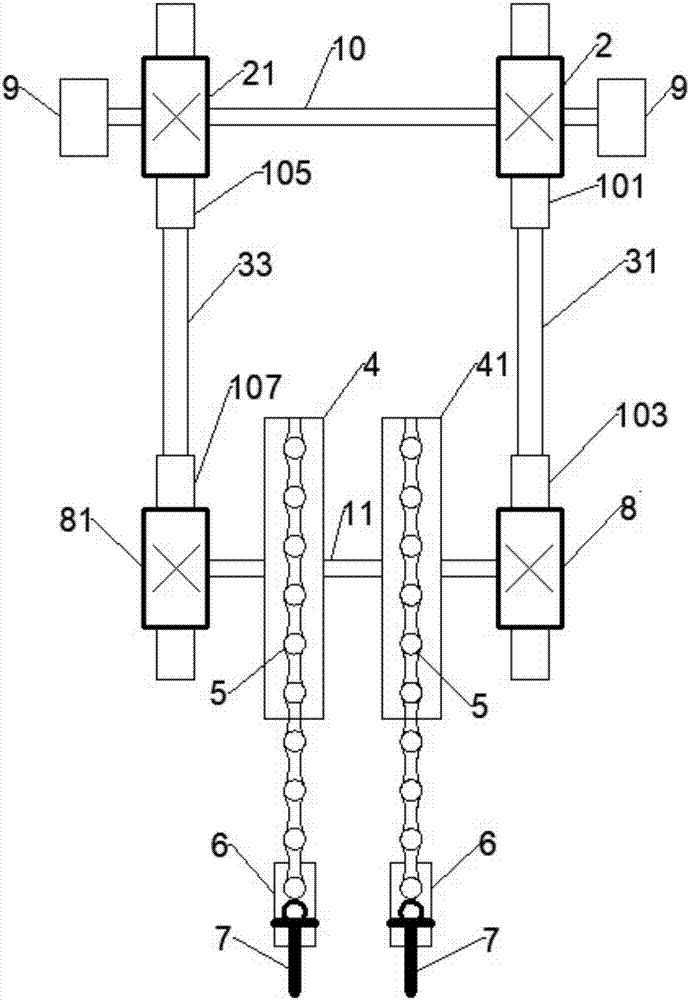

[0025] Such as figure 1 , figure 2 and image 3 As shown, a transmission mechanism of an endoscope includes a driving device 9, a housing 12, a first driving gear 2, a fixed shaft 10 of the driving gear, a first traction rack 101 in the upper section of the housing, a first push rod 31, and a first driving rack 101 in the lower section of the housing. A traction rack 103, the first driven gear 8, the fixed shaft 11 of the driven gear, the first sprocket 4, the chain 5 and the steel wire 7; wherein the driving device 9 is fixedly installed on the housing 12; the first A driving gear 2 is assembled on the fixed shaft 10 of the driving gear, and the fixed shaft 10 of the driving gear is fixedly connected with the driving device 9, and the driving device 9 provides power for the first driving gear 2; The first traction rack 101 in the upper section is meshed with the first driving gear 2, and the first driving gear 2 rotates and drives the first traction rack 101 in the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com