Assembly type telescopic bridge-shaped tray of low-voltage switchgear

A switchgear and low-voltage complete set technology, which is applied in the field of low-voltage complete switchgear assembled telescopic bridge, can solve the problems of complex processing technology, heavy busbar bridge weight, inconvenient installation, etc., and achieve simplified processing technology, good structural stability, Install and use reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

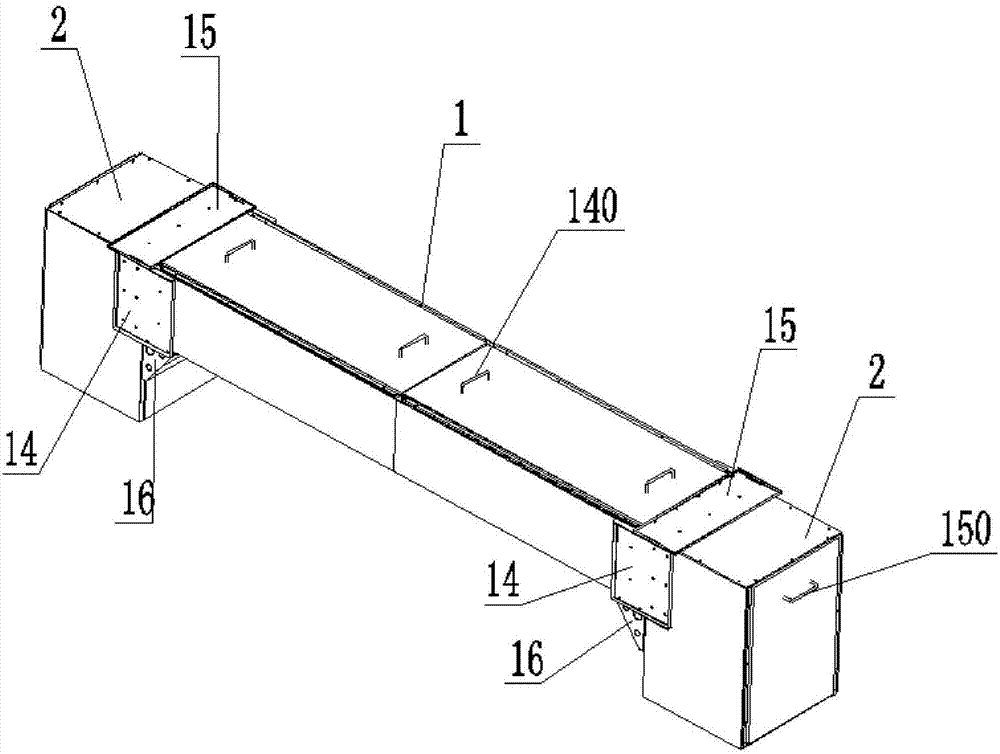

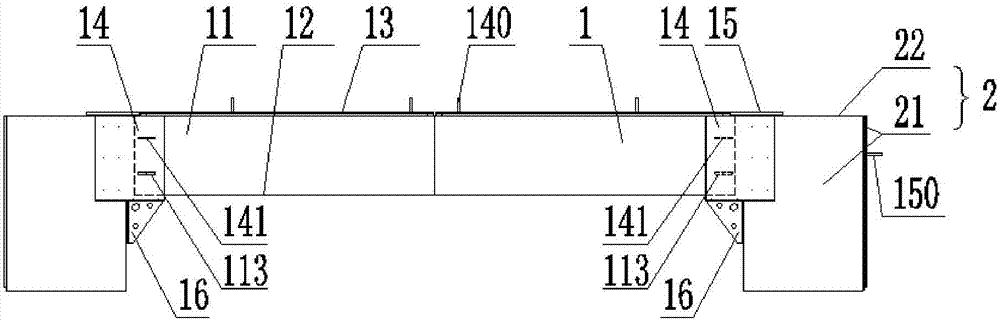

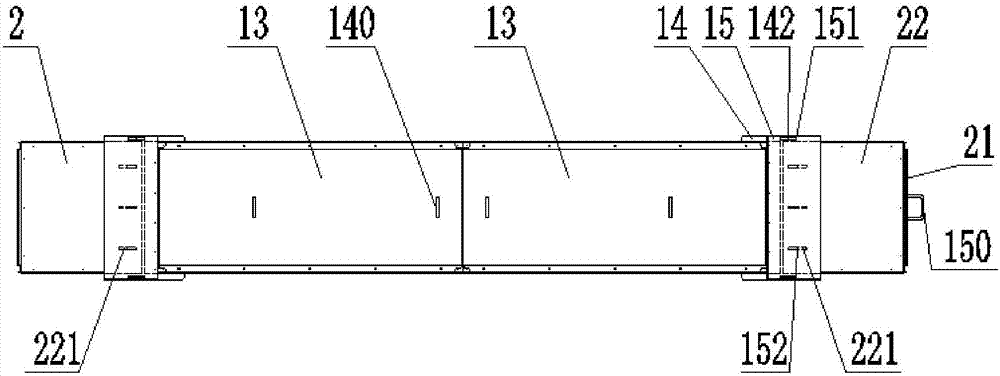

[0045] Such as Figure 1 to Figure 2 As shown, according to a preferred embodiment of the present invention, the low-voltage switchgear assembled telescopic bridge frame of the present invention includes a main bridge frame 1 and piers 2 arranged at both ends of the main bridge frame 1, wherein:

[0046] The main bridge frame 1 includes two first side plates 11 on both sides, a base plate 12 at the bottom and a first cover plate 13 at the top, and the pier 2 includes four second side plates 21 around and a second cover at the top plate 22.

[0047] Such as figure 2 , Figure 4 , Figure 9 with Figure 10As shown, the top and bottom of the first side panel 11 and the second side panel 21 respectively have a first folded edge 111, 211 vertically facing inward and a second vertical edge connected to the first folded edge 111, 211. Flange 112, 212. The two sides of the bottom plate 12 respectively have third folded edges 121 facing upwards, and the third folded edges 121 on...

Embodiment 2

[0088] The telescopic structure of the low-voltage complete switchgear assembled telescopic bridge frame of this embodiment is the same as that of Embodiment 1, the difference is that the assembled structure of the main bridge frame and the pier is different, specifically:

[0089] The two first side plates 11 and the bottom plate 12 of the main bridge frame 1 do not have bending edges, the thickness of the first side plates 11 is greater than the thickness of the screws, and the first side plates 11 are fixed by parts (such as bolt and nut assembly, screws) are directly fixed on the bottom plate 12, and the first cover plate 13 is directly fixed on the top end surface of the first side plate 11 through fixing parts (such as bolt and nut assemblies, screws) , so as to realize the assembled fixed connection.

[0090] The thickness of the second side plate 21 of the pier 2 is greater than the thickness of the screw, and the second cover plate 22 is directly fixed on the top end ...

Embodiment 3

[0093] The telescopic structure of the low-voltage complete switchgear assembled telescopic bridge frame of this embodiment is the same as that of Embodiment 1, the difference is that the assembled structure of the main bridge frame and the pier is different, specifically:

[0094] The main bridge frame 1 includes a frame with a square cross section, and a first side plate 11 , a bottom plate 12 and a first cover plate 13 fixed on the frame. The frame is composed of four longitudinal beams located at the four corners of the square in the horizontal length direction of the main bridge, and horizontal beams and vertical beams connecting the longitudinal beams. The first side plate 11, the bottom plate 12 and the second A cover plate 13 is directly fixed on the frame by a fixing member (such as a bolt and nut assembly, screw), so as to realize an assembled fixed connection.

[0095] The pier 2 includes a frame with a square cross section, four second side plates 21 and a second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com