Breaking operating device for circuit breaker

A technology for operating devices and circuit breakers, which is applied to high-voltage air circuit breakers, circuits, and air switch parts, etc., can solve the problems of large opening and tripping force, difficult parts processing, and refusal to open, and achieve stable opening. Reliability, less difficulty in parts processing, and small opening force value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

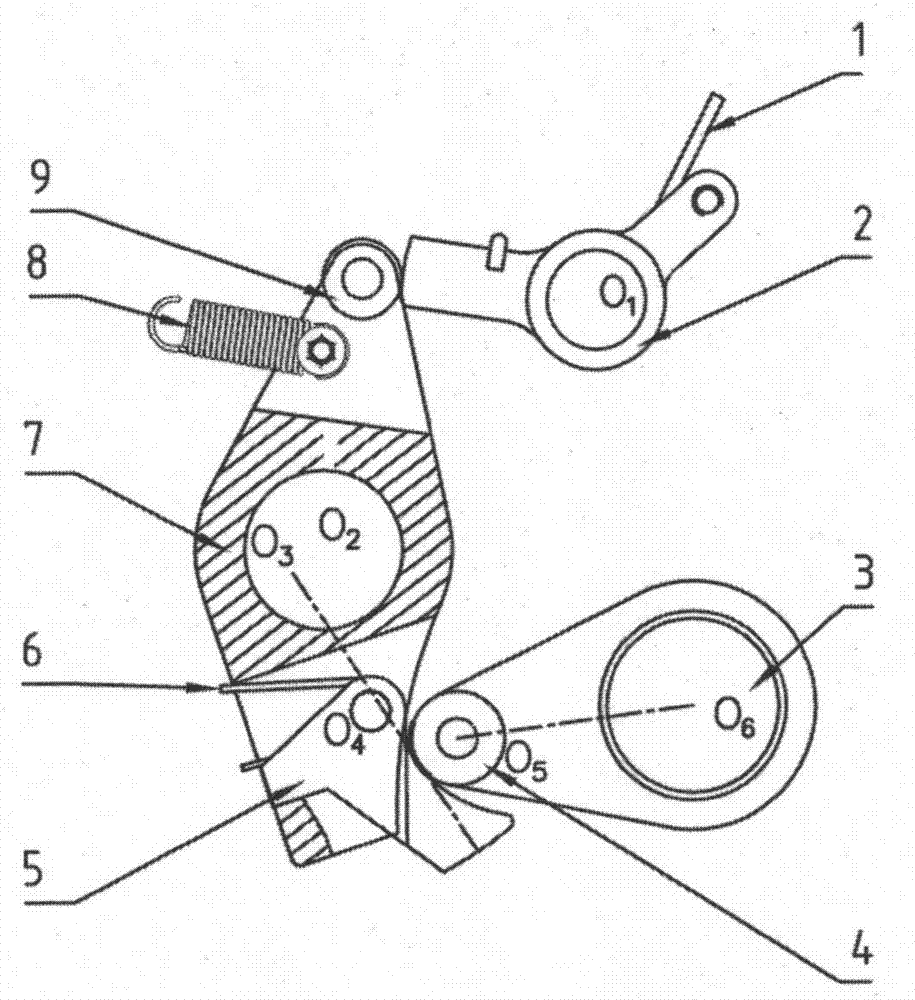

[0016] In order to make the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

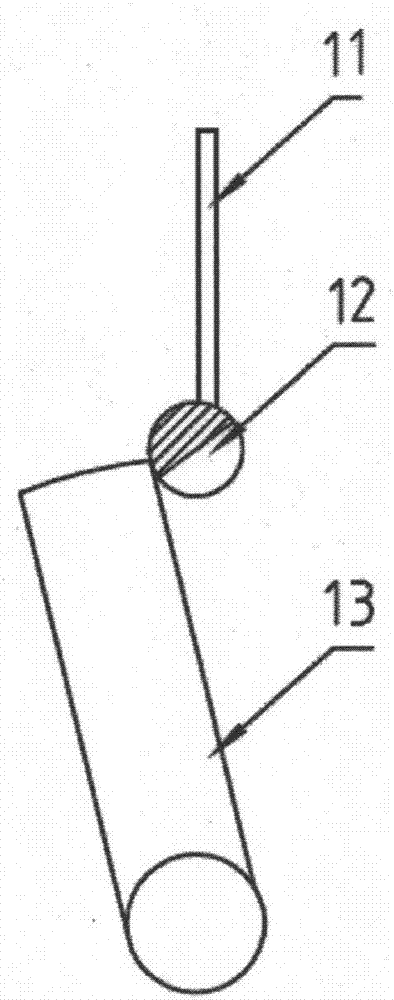

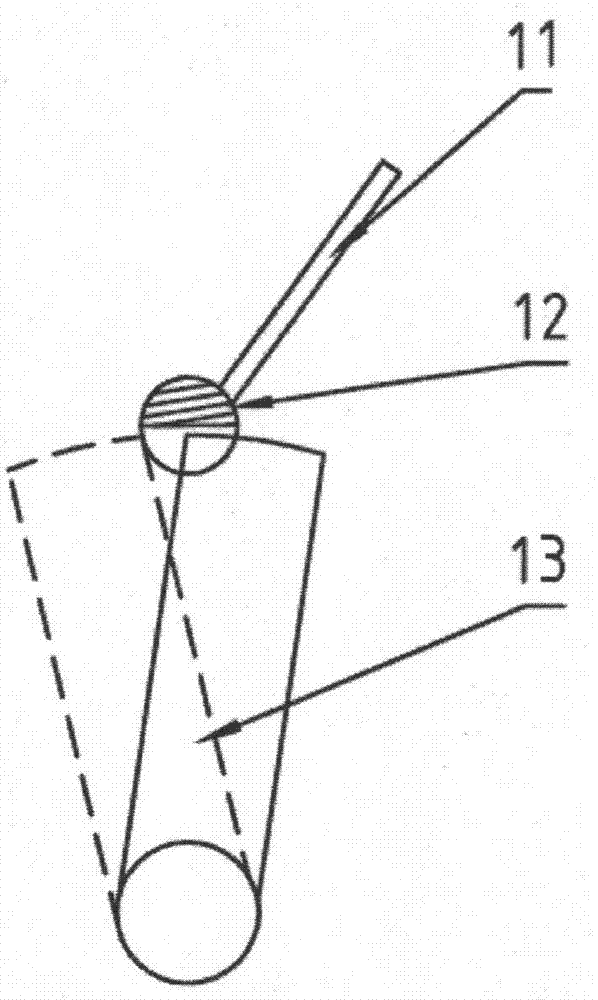

[0017] The present invention is an opening operating device for a circuit breaker, such as image 3 , Figure 4 As shown, it includes an opening torsion spring 1, an opening holding arm 2, a main shaft 3, a roller 4, a shift fork 5, a torsion spring 6, an opening detent 7, a spring 8 and A needle bearing 9. The opening and holding arm 2 can rotate around the first circle center O1, and at image 3 It can only be rotated clockwise when it is in the position. The opening keeps the front end of the turning arm 2 in a circular arc, and its center coincides with the first center O1. The force of the opening torsion spring 1 acting on the opening holding arm 2 causes the opening holding arm 2 to rotate counterclockwise. The roller 4 can rotate around the sixth circle center O6 of the main shaft 3. image 3 The position can only be turned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com