Bio-fertilizer processing device capable of conveniently and uniformly adding materials

A technology for biological fertilizers and processing devices, applied in biochemical cleaning devices, enzymology/microbiology devices, biological material sampling methods, etc. problems, to achieve the effect of improving the overall quality, adding nutrients evenly, and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

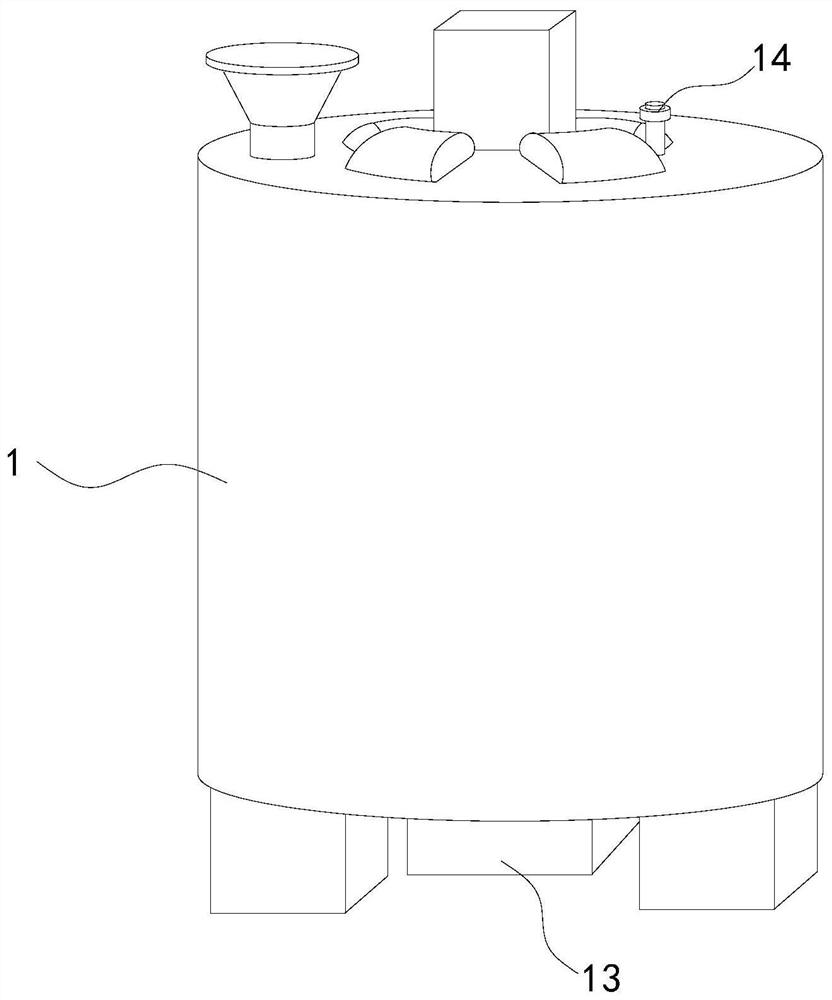

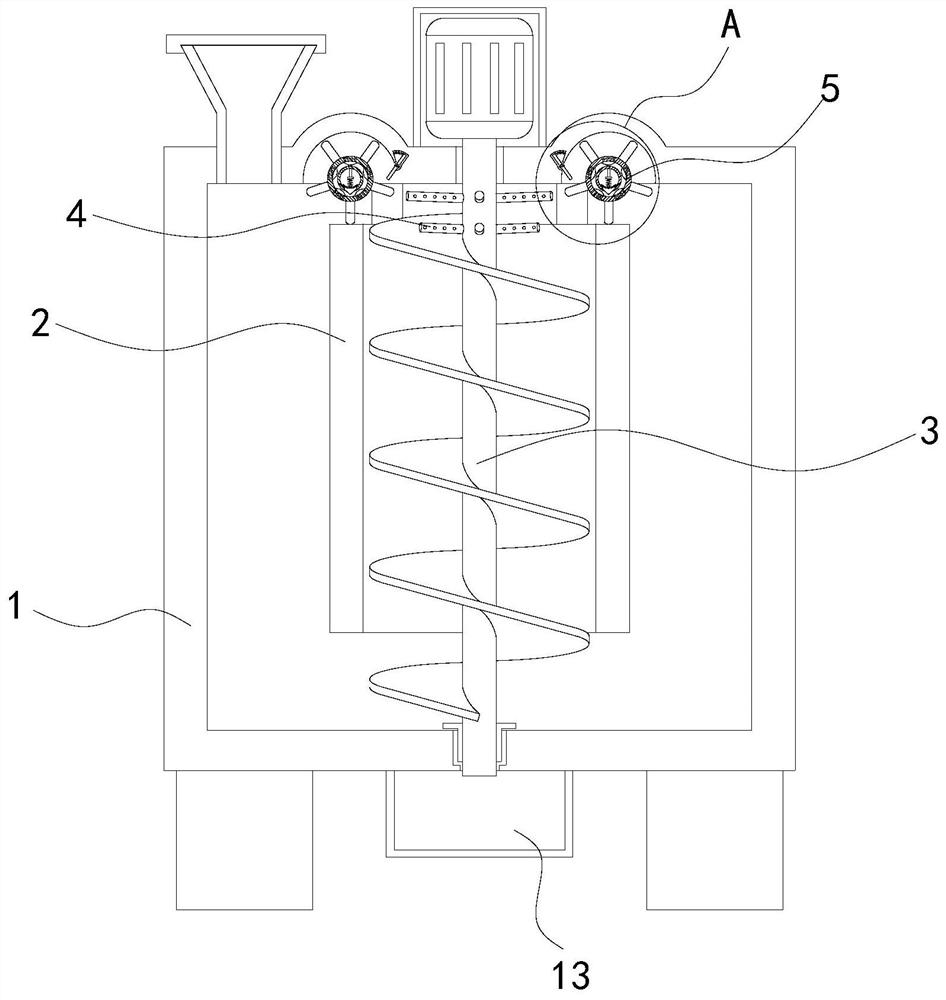

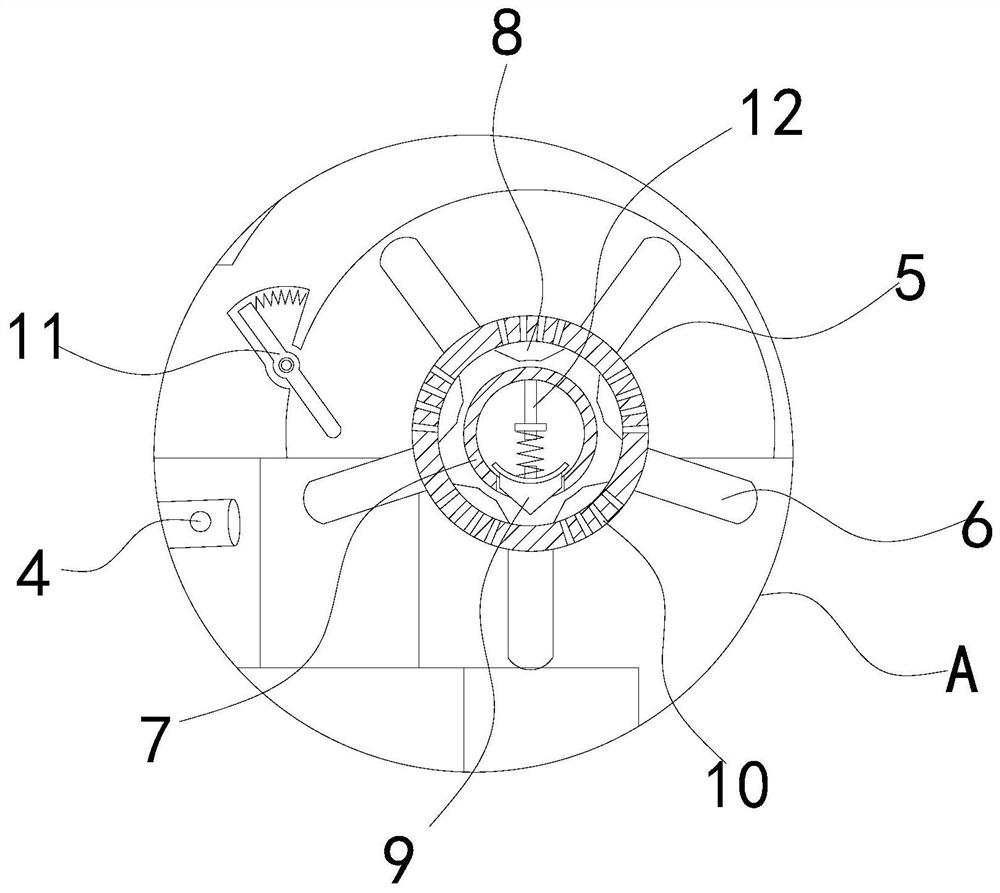

[0027] see Figures 1 to 8 , a schematic diagram of a planar structure and a schematic diagram of a three-dimensional structure of a biological fertilizer processing device for convenient and uniform feeding.

[0028] A biological fertilizer processing device for convenient and uniform feeding, comprising a device main body 1, a material partition plate 2 is fixedly installed on the inner upper end of the device main body 1, a driving rotating rod 3 is movably installed on the inner middle end of the device main body 1, and the inner upper end of the device main body 1 is movable A feeding device 5 is installed, and a nutrient pipeline 7 is fixedly installed on the upper end of the device main body 1 .

[0029] In a specific implementation, a motor is fixedly installed on the upper end of the driving rotating rod 3, and the driving rotating rod 3 is arranged on the inner side of the material partition plate 2, and a spiral piece is fixedly installed on the outside of the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com