Bubble Reactor Test Device

A test device and reactor technology, applied in the field of test benches, can solve problems such as no description or report found, no data collected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

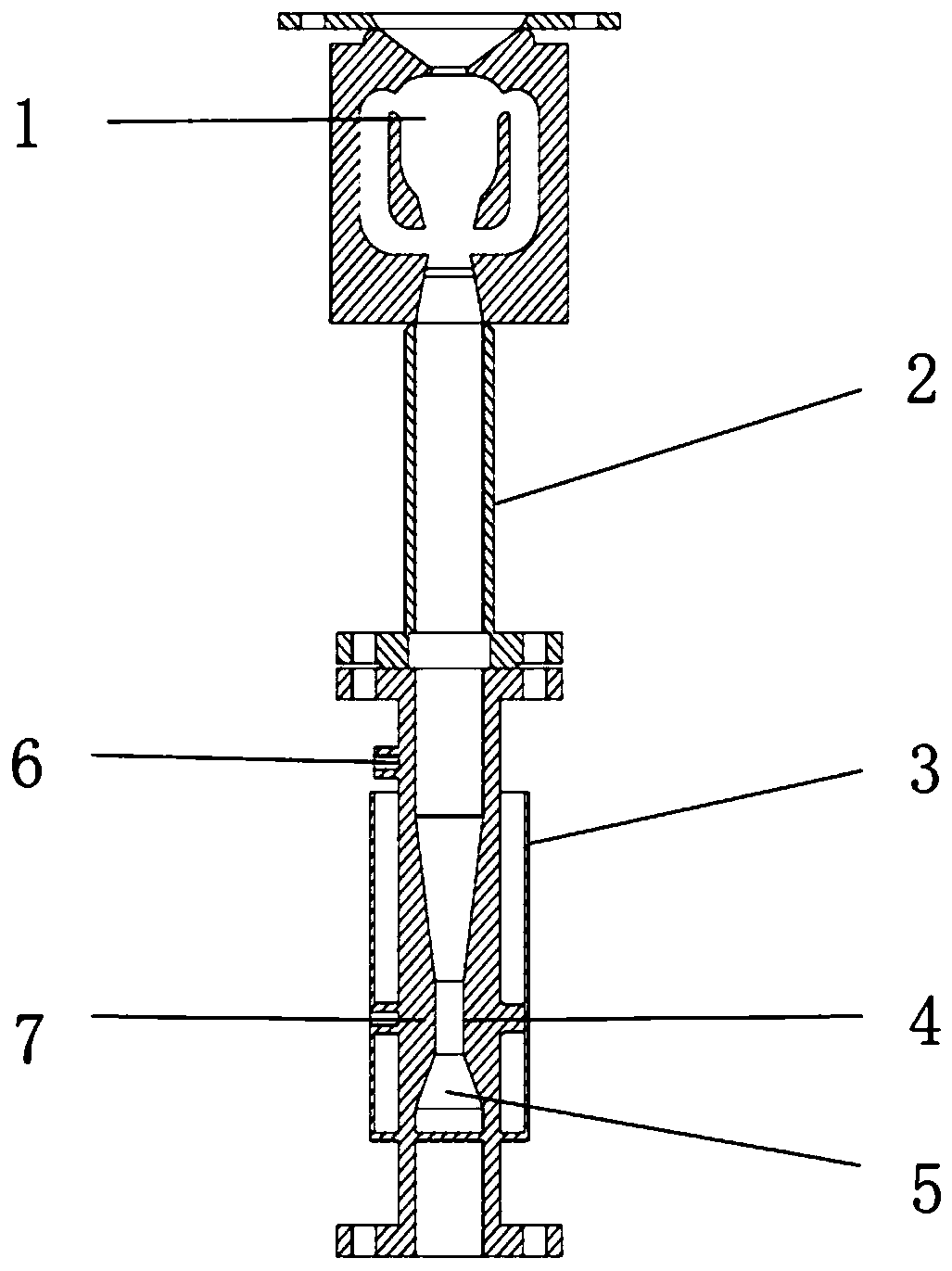

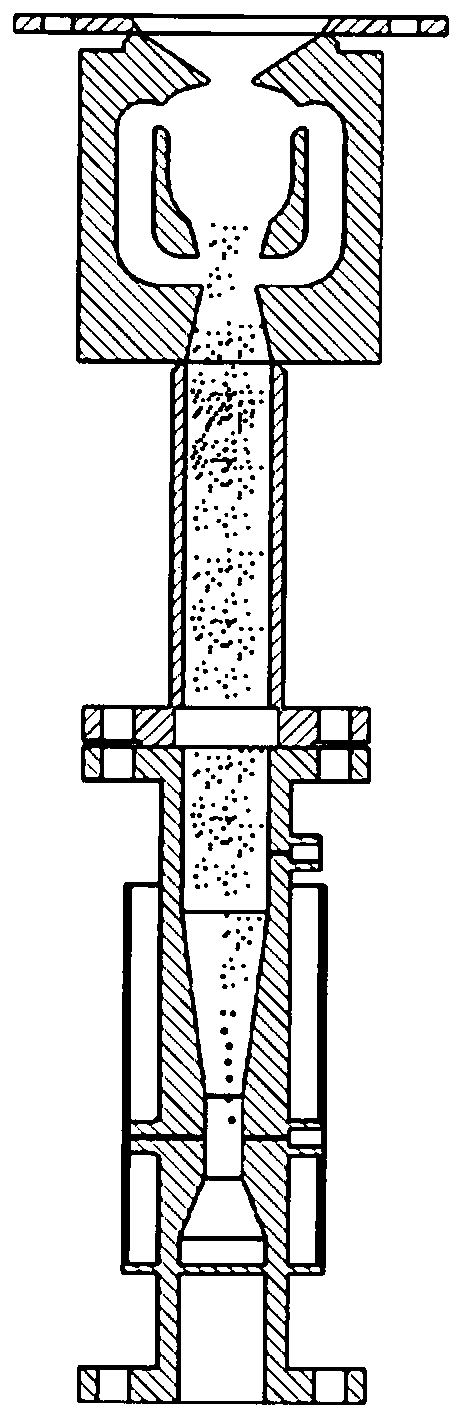

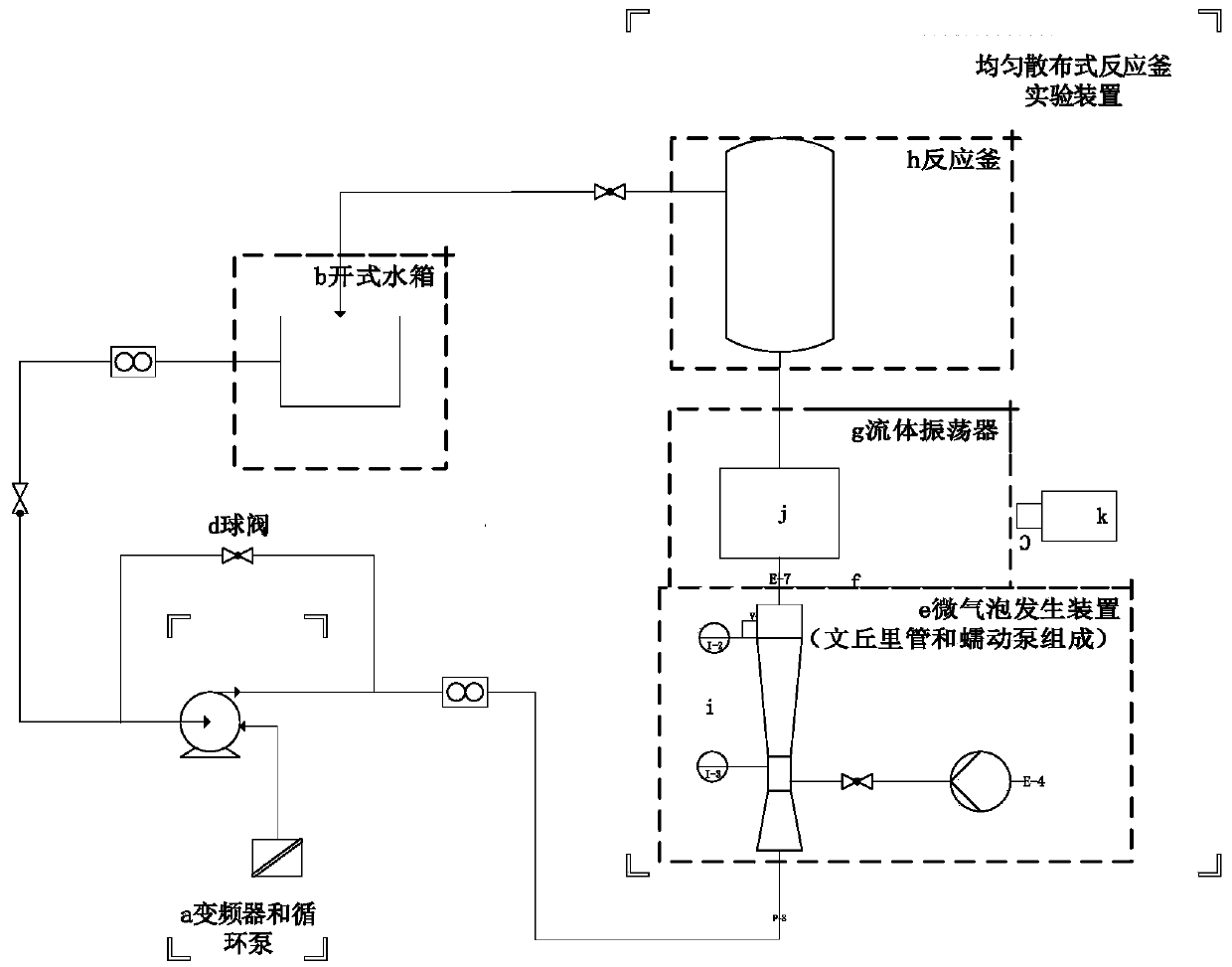

[0048] This embodiment provides a test device for a bubble reactor, including a microbubble generating device, a fluid oscillator, a reactor, a frequency conversion circulating pump, and a circulating open water tank; wherein:

[0049] The frequency conversion circulating pump is connected with the circulating open water tank through the loop pipeline;

[0050] The outlet of the variable frequency circulating pump is connected with the microbubble generating device;

[0051] The micro-bubble generating device is arranged vertically upward, and the top of the micro-bubble generating device is connected to the fluid oscillator through a square tube filter;

[0052] The upper part of the fluid oscillator is connected to the lower inlet of the reactor through a flange;

[0053] The reaction kettle is connected with a circulating open water tank through a pipeline.

[0054] Further, the outlet of the variable frequency circulating pump is connected to the microbubble generating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com