Multi-system data analysis method and platform

A data analysis and multi-system technology, applied in the field of data analysis, can solve problems such as the inability of business systems to share data centrally, achieve transparent management, ensure real-time and extensiveness, and improve the effect of refined management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

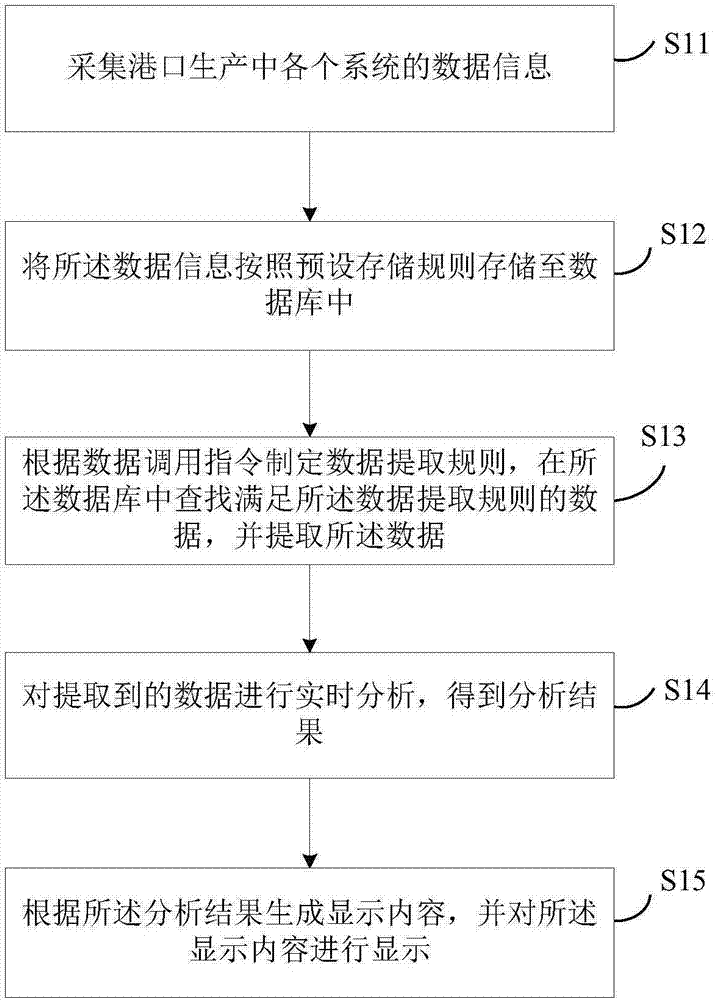

[0052] see figure 1 It is a schematic flowchart of a multi-system data analysis method provided in Embodiment 1 of the present invention, the method includes the following steps:

[0053] S11. Collect data information of various systems in port production;

[0054] Specifically, the data collection is oriented to the on-site equipment and production management process of the port, and realizes the collection of real-time data and management information.

[0055] Data collection includes:

[0056] Status information of conveying system equipment such as belt conveyors, gate valves, and protection switches;

[0057] Status information of large machinery and equipment such as dumpers, ship unloaders, stackers and reclaimers, and ship loaders;

[0058] Information on power supply equipment, including high and low voltage equipment and electrical auxiliary equipment, etc.;

[0059] Spraying equipment information, specifically including spraying and related equipment;

[0060] En...

Embodiment 2

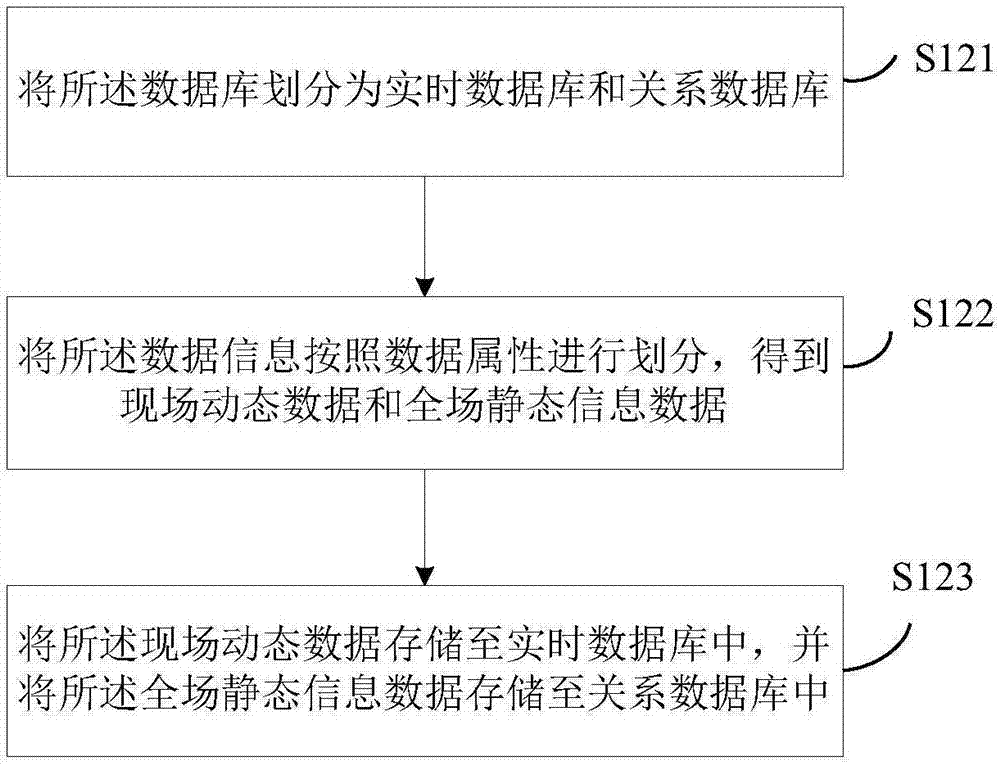

[0073] Referring to embodiment one of the present invention and figure 1 The specific process of steps S11 to S15 described in , and see figure 2 , the step S12 stores the data information in the database according to preset storage rules, specifically including:

[0074] S121. Divide the database into a real-time database and a relational database;

[0075] S122. Divide the data information according to data attributes to obtain on-site dynamic data and full-field static information data;

[0076] S123. Store the on-site dynamic data into a real-time database, and store the whole-site static information data into a relational database.

[0077] And, the method also includes:

[0078] Setting the thematic data area and the exchange data area in the real-time database and the relational database respectively, wherein the thematic data area transmits data to the exchange data area according to the predefined data content;

[0079] Through the exchange data area, a data inte...

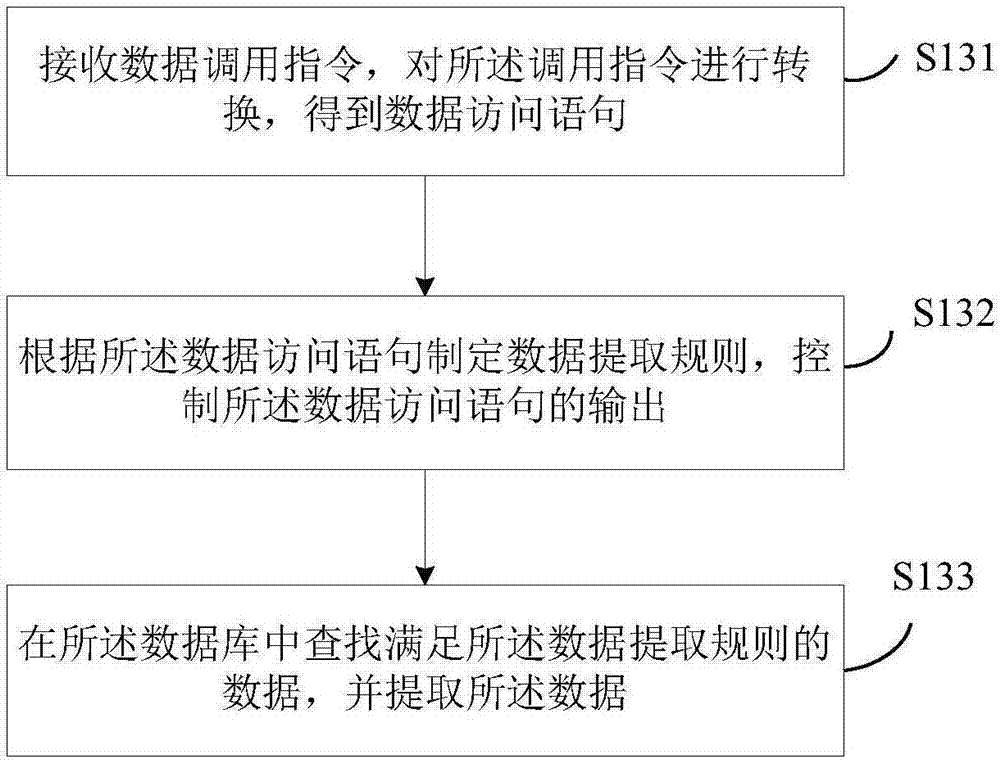

Embodiment 3

[0092] Corresponding to the multi-system data analysis method disclosed in Embodiment 1 and Embodiment 2 of the present invention, Embodiment 3 of the present invention also provides a multi-system data analysis platform, see Figure 4 , the multi-system data analysis platform provided by the present invention is designed based on SOA (Service-Oriented Architecture, service-oriented architecture), and the platform includes:

[0093] Data collection layer 1 is used to collect data information of various systems in port production;

[0094] Specifically, in the data acquisition layer, on-site equipment and production dynamic information are collected through the PLC system and HMI system, and management information and static data are collected through data binding. Among them, the data acquisition interface machine is set up, and the data is transmitted to the storage layer in the form of OPC.

[0095] The data storage layer 2 is used to store the data information in the datab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com