Sand-prevention and water-controlling sliding sleeve and opening-and-closing device thereof

A water-slip and sand-control technology, which is applied in wellbore/well valve devices, production fluids, wellbore/well components, etc., and can solve problems such as difficulty in operation, inability to effectively open, and inability to achieve infinitely segmented fracturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

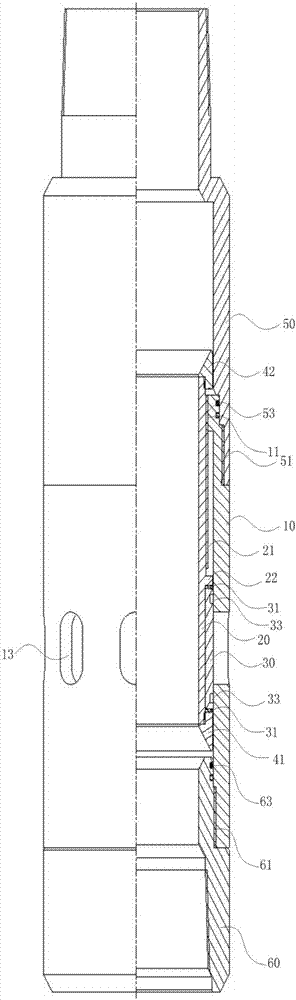

[0021] Such as figure 1 As shown, the present invention provides a sand control and water control sliding sleeve, including an outer casing 10 and a first joint 50 and a second joint 60 located at both ends of the outer casing 10; The first end is connected, and the second joint 60 is connected with the second connection of the outer sleeve 10 through the external thread 61 . Preferably, a first sealing ring 53 is provided at the connection between the first joint 50 and the outer sleeve 10 , and a second sealing ring 63 is provided at the connection between the second joint 60 and the outer sleeve 10 . The outer sleeve 10 is provided with flow holes 13 , and in this embodiment, there are a plurality of flow holes 13 , such as 6 to 10 , which are evenly arranged along the circumference of the outer sleeve 10 .

[0022] A lead screw 20 capable of moving up and down along the axial direction is arranged on the outer sleeve 10 , and the lead screw 20 is in the shape of a hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com