A kind of rolling oil applied to cold rolling extremely thin plate and preparation method thereof

A rolling oil and thin plate technology, applied in the field of rolling oil, can solve the problems of poor annealing cleanliness, inability to obtain surface quality, poor lubricity, etc., and achieve good annealing cleanliness, excellent cleanliness, and cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

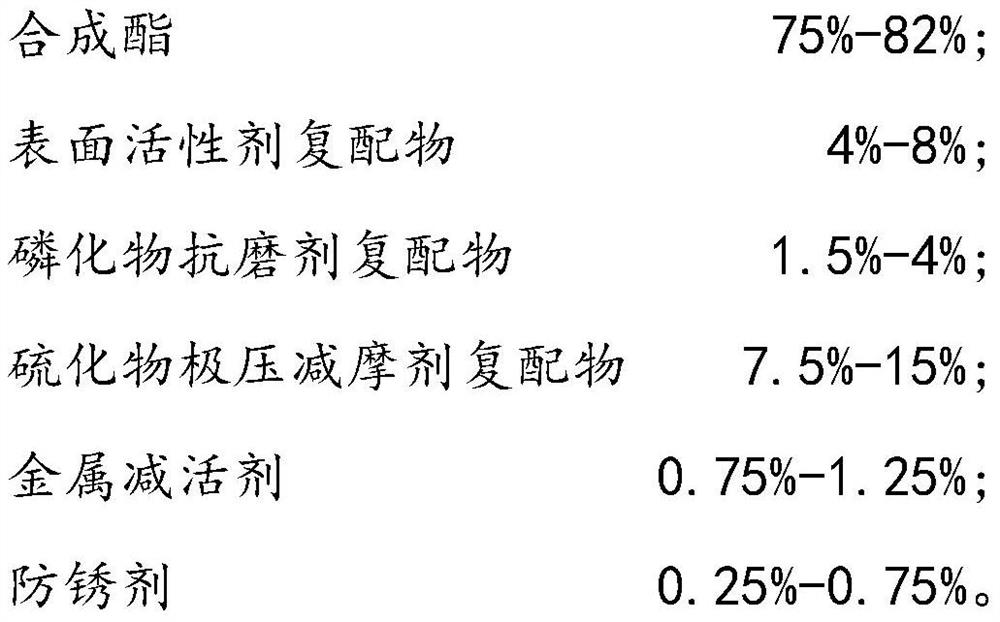

Image

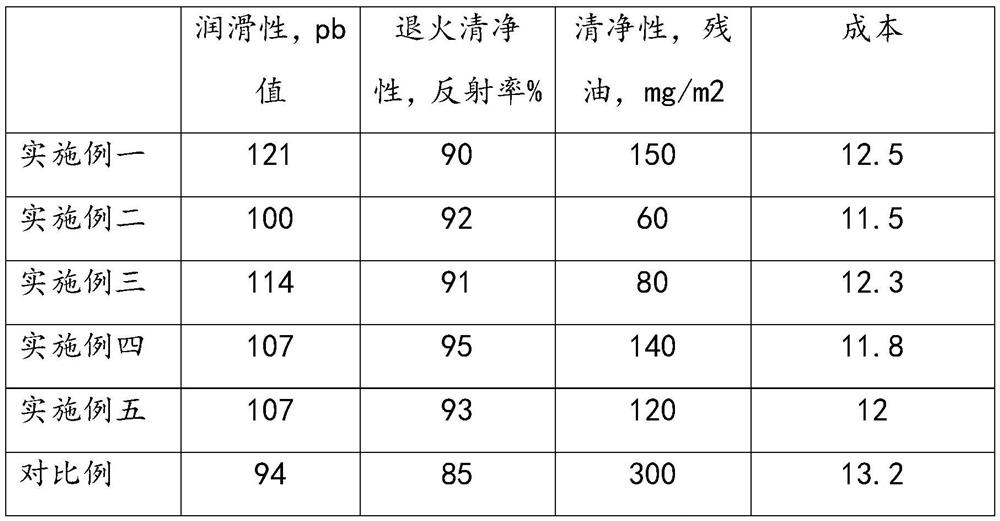

Examples

Embodiment 1

[0026] Add synthetic ester 75%; surfactant compound 4%; phosphide antiwear compound 4%; sulfide extreme pressure friction reducer compound 15%; metal deactivator 1.25%; rust inhibitor 0.75 %.

[0027] The preparation method comprises the following steps:

[0028] 1) according to above-mentioned proportioning, prepare the preparation material of the rolling oil that is applied to cold-rolled extremely thin plate;

[0029] 2) The prepared materials were mixed and stirred for 3 hours under the temperature condition of 50°C.

[0030] in:

[0031] Synthetic esters include trimethylolpropane 63.6%, oleic acid 11.6%, coconut oleic acid 13.52% and dimer acid 11.24%.

[0032] The surfactant complex includes nonionic surfactant NP-4,2% and cationic surfactant T-5,2%,

[0033] Phosphide antiwear compounds include T306 Trimethyl Phosphate, 2% and Lubrizol 360-P, 2%.

[0034] Sulfide extreme pressure friction reducer compounds include D.O.G MD16 (sulfurized fatty acid ester), 6%, Dove...

Embodiment 2

[0038] Add synthetic ester 82%; surfactant compound 8%; phosphide antiwear compound 1.5%; sulfide extreme pressure friction reducer compound 7.5%; metal deactivator 0.75%; rust inhibitor 0.25% %.

[0039] The preparation method comprises the following steps:

[0040] 1) according to above-mentioned proportioning, prepare the preparation material of the rolling oil that is applied to cold-rolled extremely thin plate;

[0041] 2) The prepared materials were mixed and stirred for 2 hours under the temperature condition of 70°C.

[0042] in:

[0043] Synthetic esters include trimethylolpropane 63.6%, oleic acid 11.6%, coconut oleic acid 13.52% and dimer acid 11.24%.

[0044] The surfactant complex includes nonionic surfactant NP-6,4% and cationic surfactant T-10,4%,

[0045] The phosphide antiwear compound includes T306 trimethyl phosphate 1% and Lubrizol 360-P, 0.5%.

[0046] Sulfide extreme pressure friction reducer compounds include D.O.G MD16, 3%, Dover 1351, 3% and Ryan ...

Embodiment 3

[0050] Add synthetic ester 77%; surfactant compound 7%; phosphide antiwear compound 2%; sulfide extreme pressure friction reducer compound 12.5%; metal deactivator 1%; rust inhibitor 0.5 %.

[0051] The preparation method comprises the following steps:

[0052] 1) according to above-mentioned proportioning, prepare the preparation material of the rolling oil that is applied to cold-rolled extremely thin plate;

[0053] 2) The prepared materials were mixed and stirred for 2 hours under the temperature condition of 60°C.

[0054] in:

[0055] Synthetic esters include trimethylolpropane 63.6%, oleic acid 11.6%, coconut oleic acid 13.52% and dimer acid 11.24%.

[0056] The surfactant complex includes nonionic surfactant NP-4, 4% and cationic surfactant T-10, 3%.

[0057] The phosphide antiwear compound includes T306 trimethyl phosphate 1% and Lubrizol 360-P, 1%.

[0058] Sulfide extreme pressure friction reducer compounds include D.O.G MD16,5%, Dover 1351,5% and Lane 2540,2.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com