Abrasion-proofing, puncturing-preventing and safe retreaded tire

A safe technology for retreading tires, which is applied to tire components, tire tread/tread pattern, tire edges, etc., can solve the problem of dislocation between the retreaded tire surface and the old tire body, affect the normal use of retreaded tires, and fit soft edges It is easy to withstand problems such as pulling, so as to ensure the fit, ensure the puncture resistance, and improve the effect of pulling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

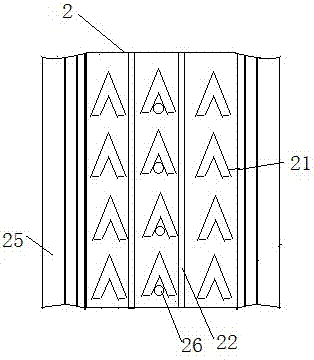

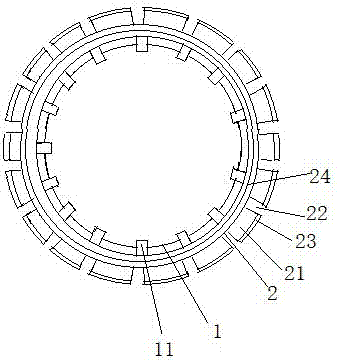

[0019] Such as Figure 1-2 A wear-resistant and puncture-resistant safety retreaded tire shown includes an old tire body 1 and a retreaded tire surface 2, the retreaded tread 2 is glued to the outside of the old tire body 1, and the tread of the old tire body 1 Stripe grooves 11 arranged longitudinally are provided, and a buffer layer is arranged inside the stripe grooves 11; pattern blocks 21 and anti-skid grooves 22 formed by pattern grooves are arranged on the outer peripheral surface of the retreaded tire surface 2, and the pattern blocks 21 surface is provided with wear-resisting layer 23, and described retread tire surface 2 inner side is provided with snap-in strip and anti-puncture liner 24; A soft edge 25 is provided on the side, and a cord layer and a puncture-resistant inner liner 24 are arranged on the inner side of the soft edge 25 , and the cord layer is arranged on the lower side of the puncture-resistant inner liner 24 .

[0020] In this embodiment, the punctu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com