Automatic grinding sieving machine

A technology of screening machine and grinding mechanism, which is applied in the direction of sieve, solid separation, grid, etc., can solve the problems of unguaranteed product particle accuracy and rough grinding, and achieve simple structure, high grinding particle fineness, and grinding screen material. integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

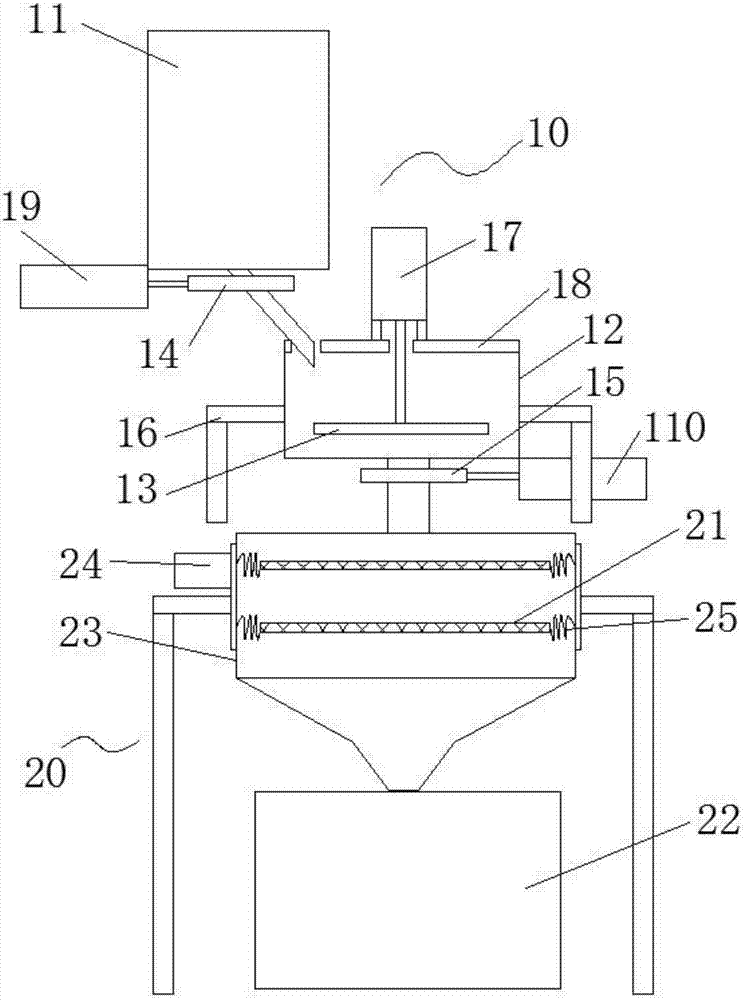

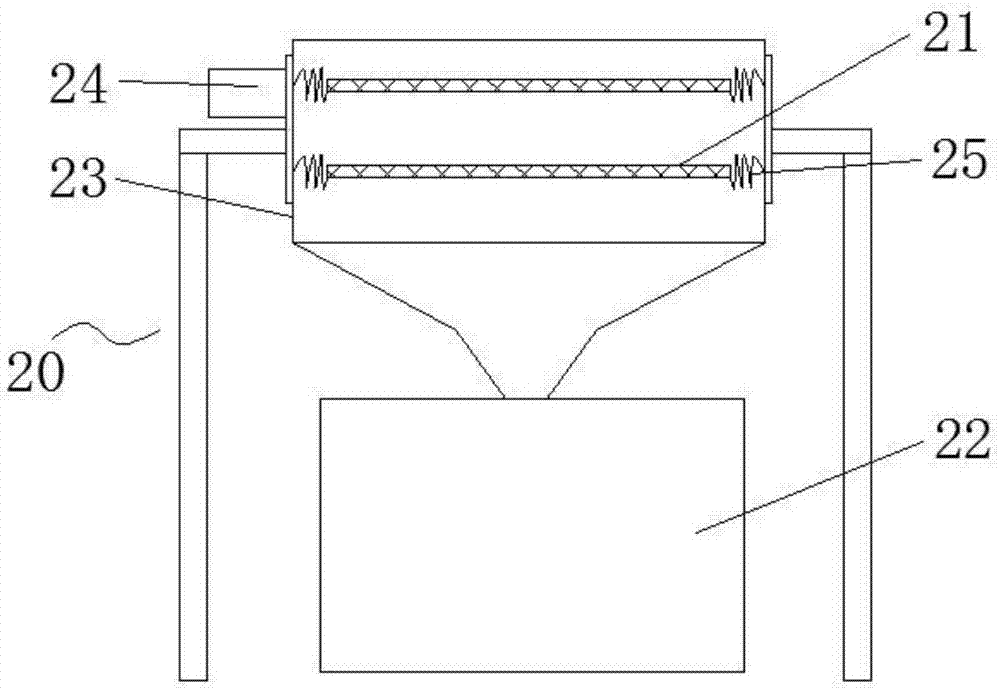

[0022] see figure 1 , the automatic grinding and sifting machine of the present invention includes a grinding mechanism 10 and a sieving mechanism 20; Above, the bottom of the feed box 11 is provided with a feed port, the feed port is provided with a feed baffle 14, the grinding block 13 is arranged in the grinder 12, and the bottom of the grinder 12 is provided with a discharge hole, the discharge hole is provided with a discharge baffle 15; the screening mechanism 20 includes a screen 21 and a container 22, and the screen 21 is arranged on the discharge hole of the grinder 12 Below, the container 22 is located below the screen 21 .

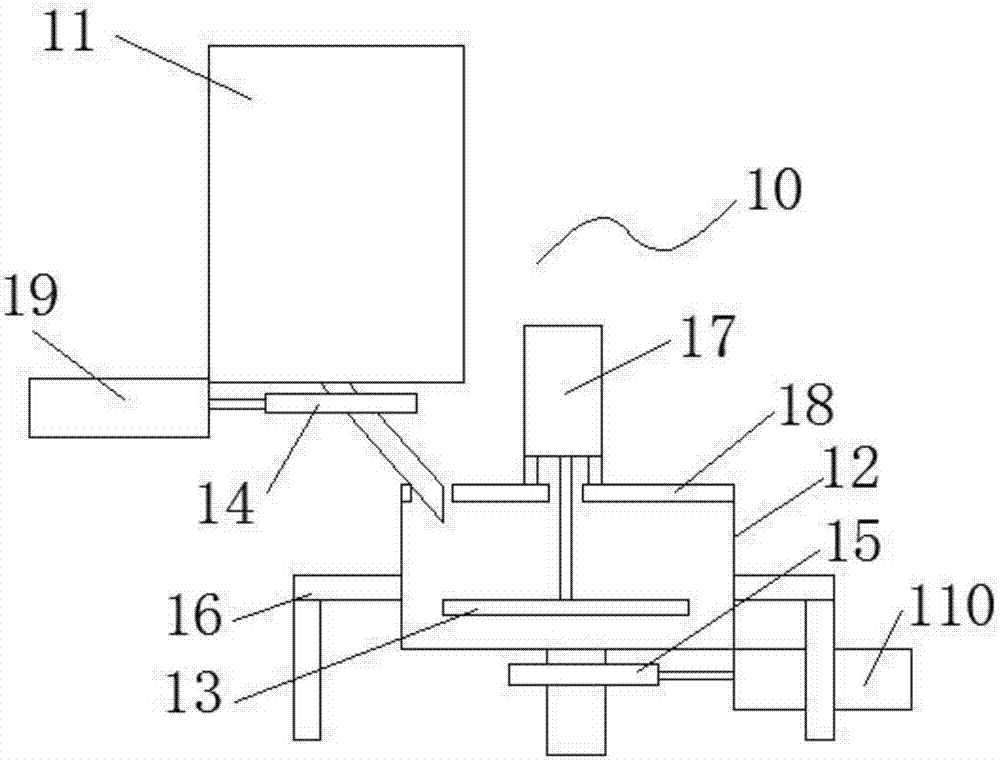

[0023] see figure 2 , The grinding mechanism 10 of this embodiment also includes a grinding frame 16 , a grinding motor 17 , a grinding cover 18 , a feeding baffle pushing cylinder 19 and a discharge baffle pusher 110 .

[0024] The grinder 12 is fixed on the grinding frame 16 . The grinding motor 17 is mounted on the grinder 12 , and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com