Test-tube membrane component and membrane accumulator with same

A technology of membrane modules and accumulators, applied in the field of energy storage, can solve problems such as adaptability, lack of flexibility, and poor working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

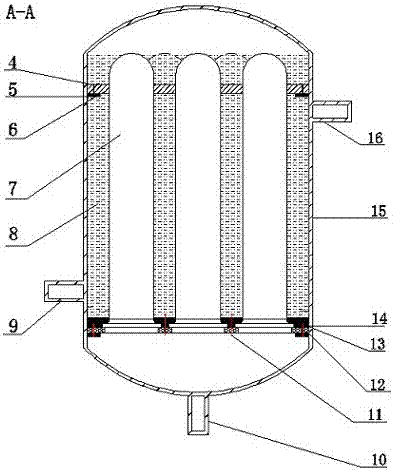

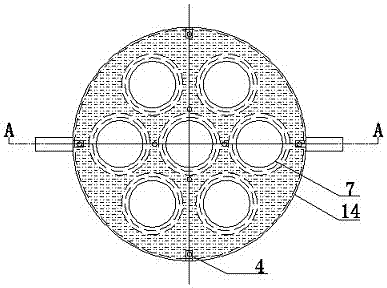

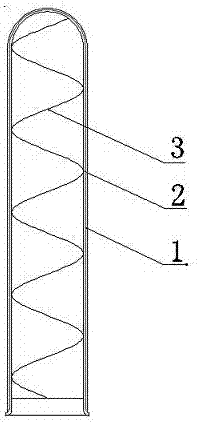

[0012] see figure 1 , and combined with figure 2 , test tube membrane module and its membrane accumulator, including fixing bolt 4, positioning plate 5, support orifice plate 6, test tube membrane module 7, solution 8, solution outlet connection 9, steam connection 10, fastening bolt 11, seal Lower orifice plate 12, sealing packing 13, sealing upper orifice plate 14, shell 15 and solution inlet connecting pipe 16. The supporting orifice plate 6 is fixedly connected with the housing 15 through the positioning plate 5 and the fastening bolt 4 . The test tube type membrane module 7 is embedded in the supporting orifice plate 6 to fix the position. The porous support 2 and the support frame 3 are used to support the test tube membrane module 7 and form a steam channel in the middle. At the open end of the test tube membrane module 7, use the sealing upper orifice plate 14, the sealing lower orifice plate 12 and the sealing packing 13 to seal the test tube type membrane module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com