Novel rotational rectifying component

A technology of rotating rectification and components, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as bolt breakage, and achieve the effect of avoiding breakage and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

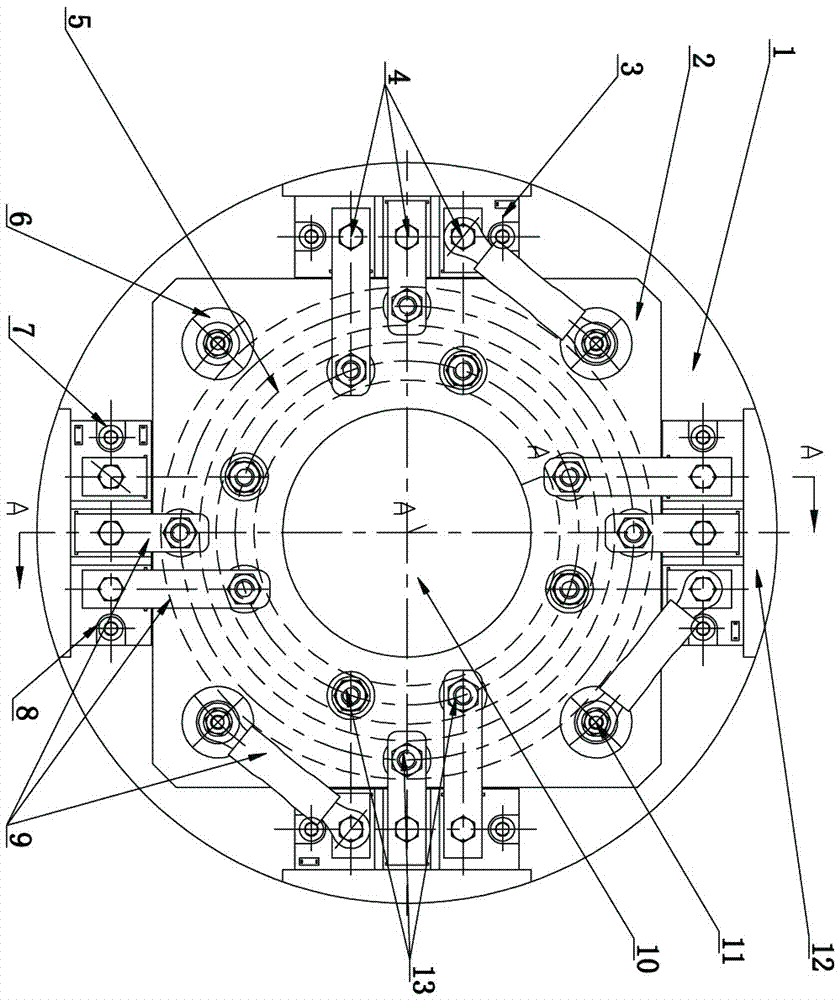

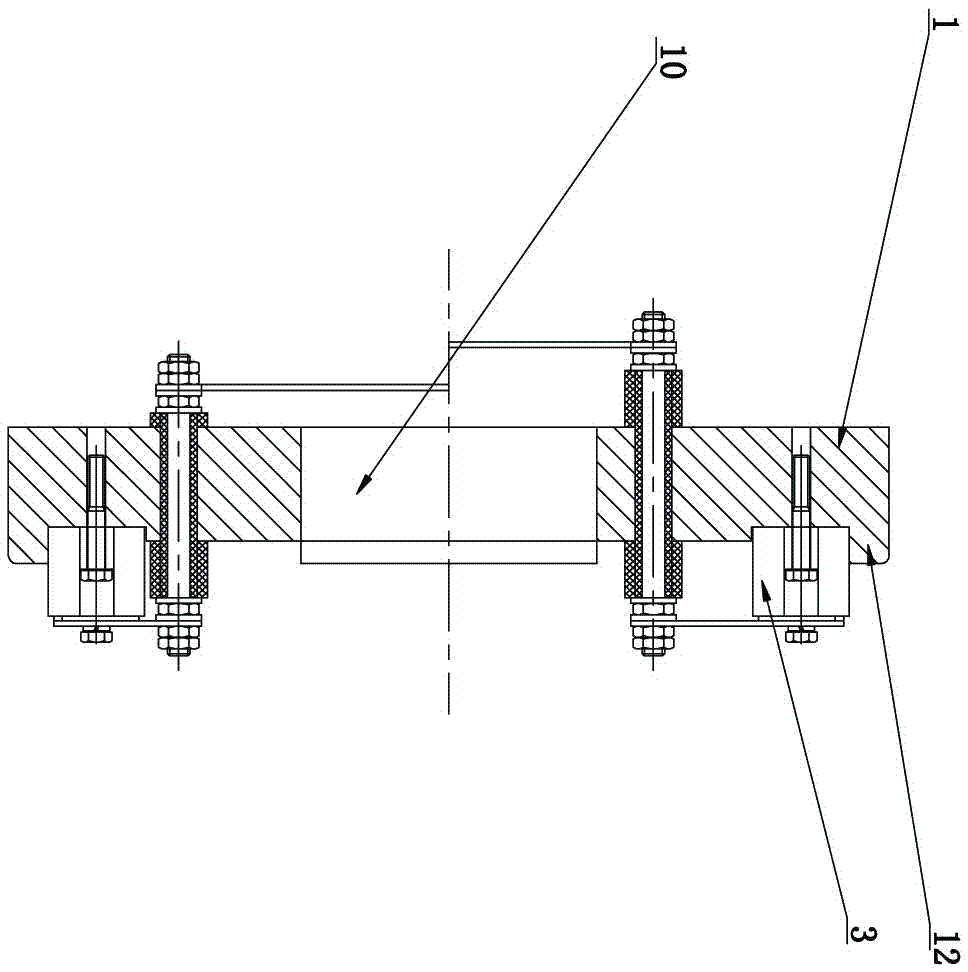

[0015] The purpose of the present invention is achieved in this way: a new type of rotary rectification assembly, including a rectification seat body 1, the rectification seat body 1 is arranged in a circular shape, a square fixing seat 2 is arranged on the rectifying seat body 1, and four square fixing seats 2 The corners are respectively provided with bolt fixing bases 6, bolt fixing holes are arranged between two adjacent bolt fixing bases 6, a large hole 10 is arranged from the center of the square fixing seat 2 to the center of the rectifying seat body 1, and the rectifying seat body 1 Steps 12 are respectively provided at the front, rear, left, and right positions on the top; rectifier disc 5 is provided on the square fixed seat 2, and through-holes 13 are arranged on the position of rectifier disc 5 corresponding to the bolt fixing holes. The rectifier seat body 1 is provided with a fixed block 3, and the fixed block 3 is provided with three sets of connection holes 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com