Finite element analysis-based complex plate shell thickness quick optimization design method

An optimization design and finite element technology, applied in the field of rapid optimization design of mechanical structures, can solve problems such as complex, special plate and shell structure, difficult theoretical calculation of plate and shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the content of the present invention is not limited to the stated scope.

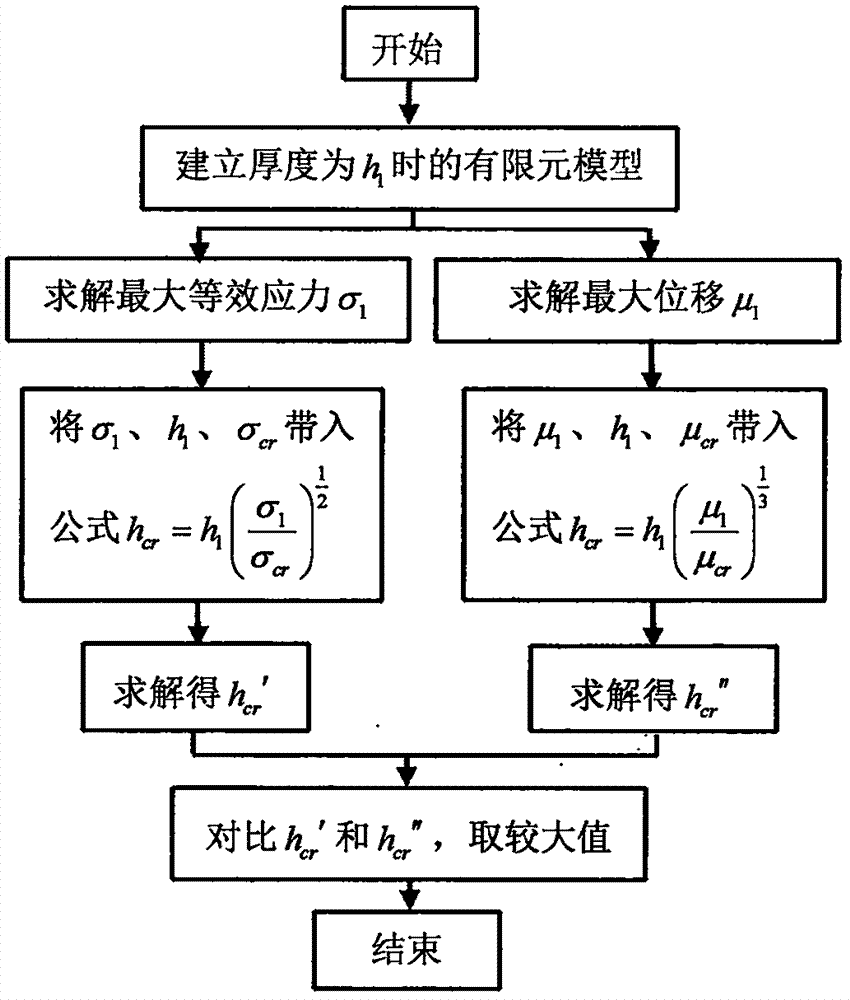

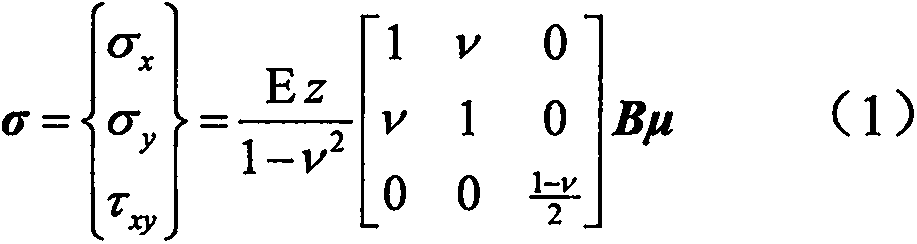

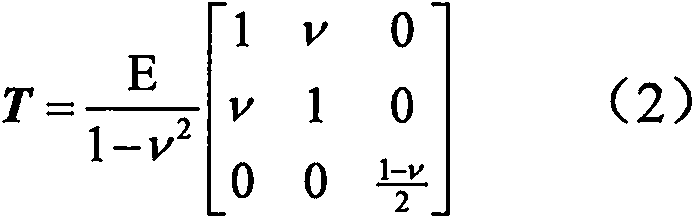

[0052] Embodiments of the invention: attached figure 1 It is a method step diagram of the present invention, according to the theoretical relationship between the stress, load, displacement and stiffness matrix in the finite element theory and the plate and shell theory, the optimal plate and shell thickness calculation formula based on the maximum equivalent stress and maximum displacement is deduced respectively : Suppose the thickness is h 1 and h cr The plate and shell structure is a plate and shell structure with the same network type and network division, boundary conditions and loads, anisotropic materials, and only different thicknesses, where the thickness h 1 is an arbitrary known initial value, the thickness h cr unknown, h cr In order to meet the corresponding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com