Anti-fatigue safety glasses and production method thereof

A production method and anti-fatigue technology, applied in optics, instruments, optical components, etc., can solve problems such as inability to block harmful blue light, high lens surface, and visible light due to visual fatigue, so as to protect safety, reduce process chains, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

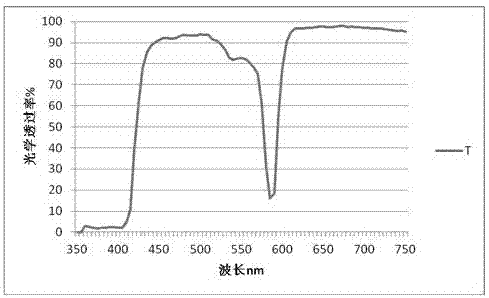

[0026] Embodiment 1: with reference to attached figure 1 Shown, a kind of anti-fatigue safety lens, described lens comprises a resin substrate and the exterior coating on its surface, and described exterior coating is hard coating layer, and the thickness of described hard coating layer is within 5 μm, and the The above-mentioned hardened coating layer includes an antistatic agent, an absorbent, an additive, and a hardening liquid. The absorbent can block harmful blue light of 380nm-420nm, and the additive can block visible light with a narrow band wavelength near 585nm; the antistatic agent is SN anti- Static agent, the dosage is between 0.01% and 5%. The absorber is light stabilizer TM46, which can absorb harmful blue light from 380nm to 420nm. The dosage is between 0.1% and 5%. The additive is functional Absorber ABS584, which can absorb 60%-90% of 585nm narrow-band visible light, the addition amount is between 0.1%-5%; the hardening liquid includes one or more of water, me...

Embodiment 2

[0034] Embodiment 2: Different from Embodiment 1:

[0035] 2) Solution preparation: Add specific 1.0% TM46 anti-blue light machine, 200PPM SN antistatic agent and 1.0% ABS584 visible light absorber to MP7110 hardening machine used for hardening machine, stir and mix well, then add 5μm for hardening machine The filter element circulates for 24 hours;

Embodiment 3

[0036] Embodiment 3: Different from Embodiment 1:

[0037] 2) Solution preparation: Add specific 1.0% TM46 anti-blue light machine, 500PPM SN antistatic agent and 1.0% ABS584 visible light absorber to the hard top coating MP7110 used for the hardening machine. After fully stirring and mixing, add 5 μm for the hardening machine The filter element circulates for 24 hours.

[0038] The process of the present invention is suitable for resin lens substrates whose refractive indices are 1.499 (CR39), 1.56 (KOC55 and NK55), 1.53 (trivex), 1.59 (PC) and 1.60, 1.67, 1.74 Mr series.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com