Test device of oil and gas suspension system

A technology of oil-pneumatic suspension and test device, which is applied in the direction of vehicle suspension/shock absorbing mechanism testing, etc. It can solve the problems of increasing the number of excitation hydraulic cylinders and increasing the cost of test benches, so as to reduce test costs, avoid motion interference and errors, and test high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

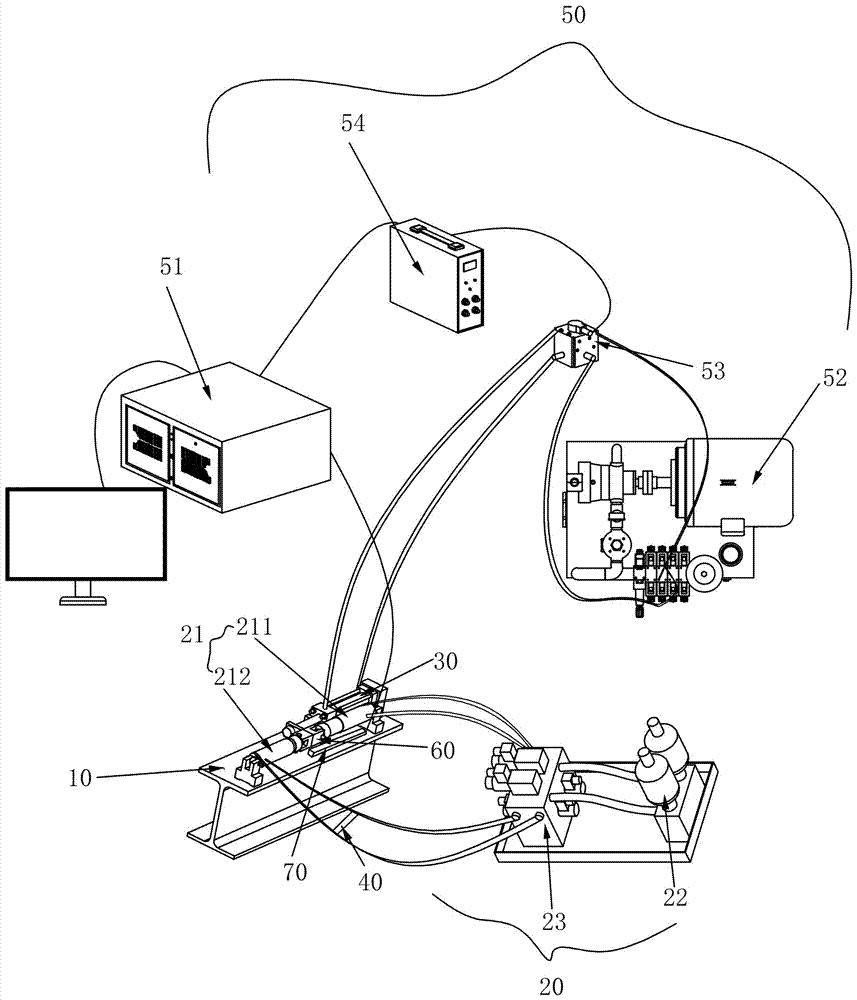

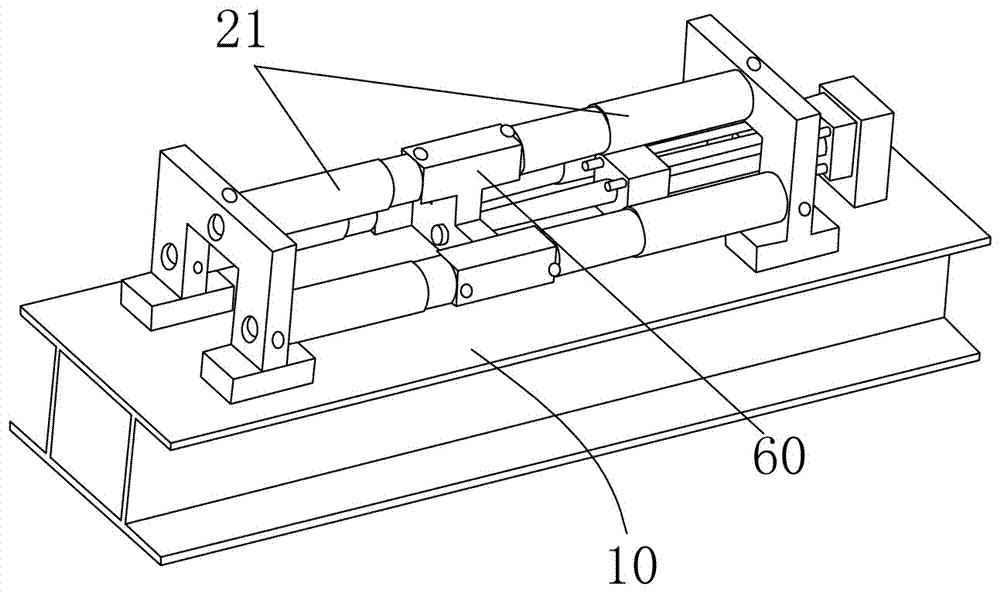

[0021] Such as figure 1 As shown, a test device of a hydropneumatic suspension system of the present invention includes a base 10, a hydropneumatic suspension system 20, an excitation hydraulic cylinder 30, a pressure sensor 40 connected to the excitation hydraulic cylinder 30, and a device for controlling the movement of the excitation hydraulic cylinder 30. Hydraulic servo control system 50.

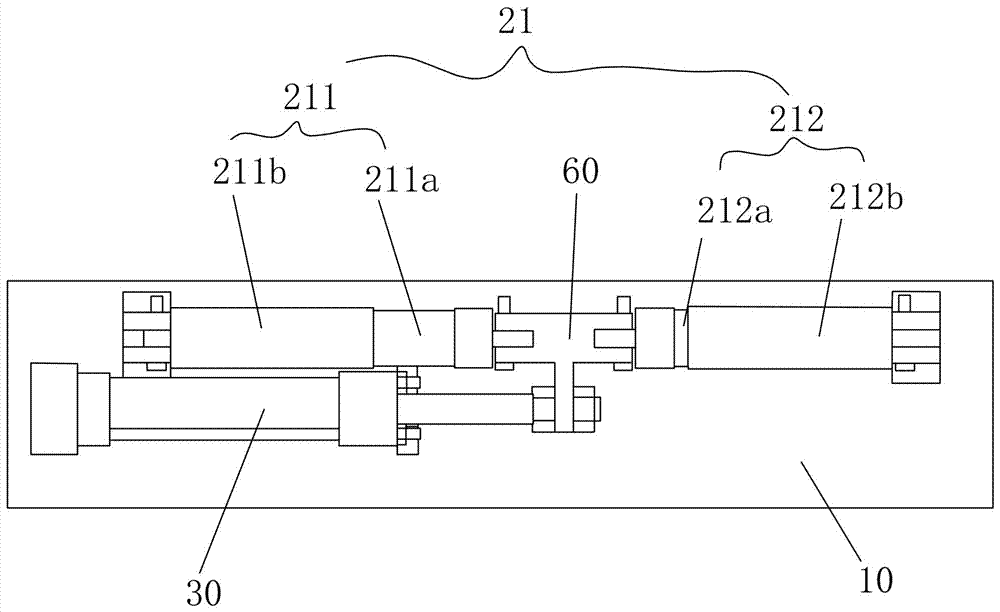

[0022] The oil-pneumatic suspension system 20 includes one or more groups of oil-pneumatic suspension cylinders 21 installed on the base 10, accumulators 22 connected to the oil-pneumatic suspension cylinders 21 through pipelines, and oil circuit control valve blocks 23 arranged on the pipelines . combine image 3 , image 3 It is a schematic layout diagram of a group of oil-pneumatic suspension cylinders 21 of the present invention, the rod chamber 211...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com