Multi-degree of freedom injection device for sintering and use method of same

A technology of blowing device and degree of freedom, which is applied in the field of blowing device and multi-degree-of-freedom blowing device, which can solve the problems that the distance is difficult to ensure a reasonable range, the degree of freedom is not high, and the distance is difficult to guarantee, so as to improve the degree of freedom and Adjustability, degree of freedom and adjustability are improved, and the effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

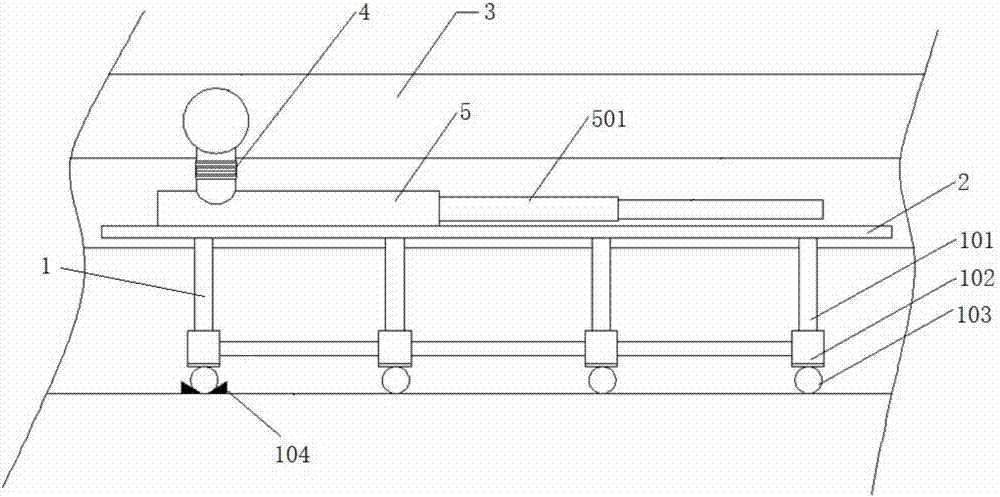

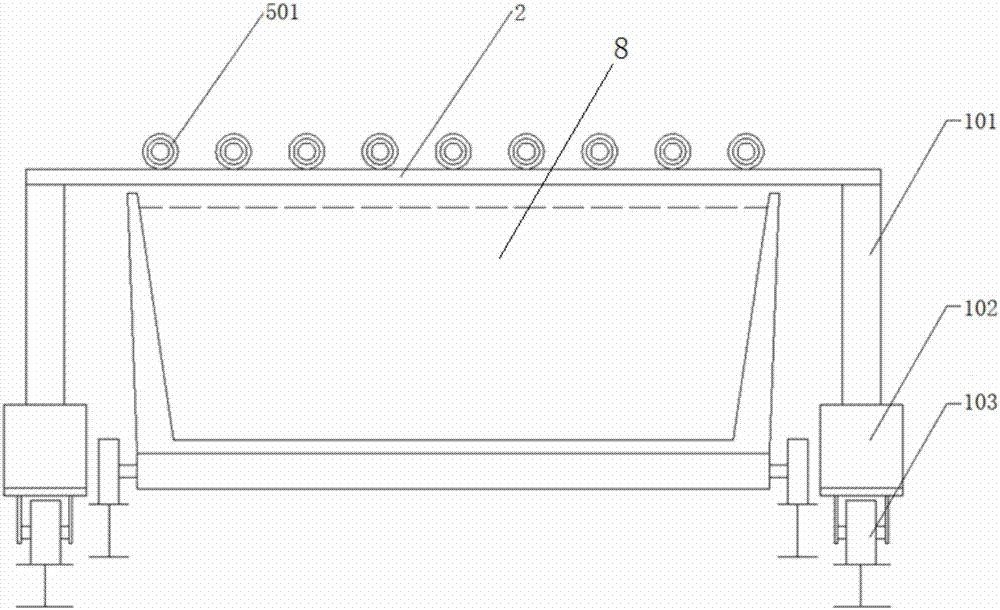

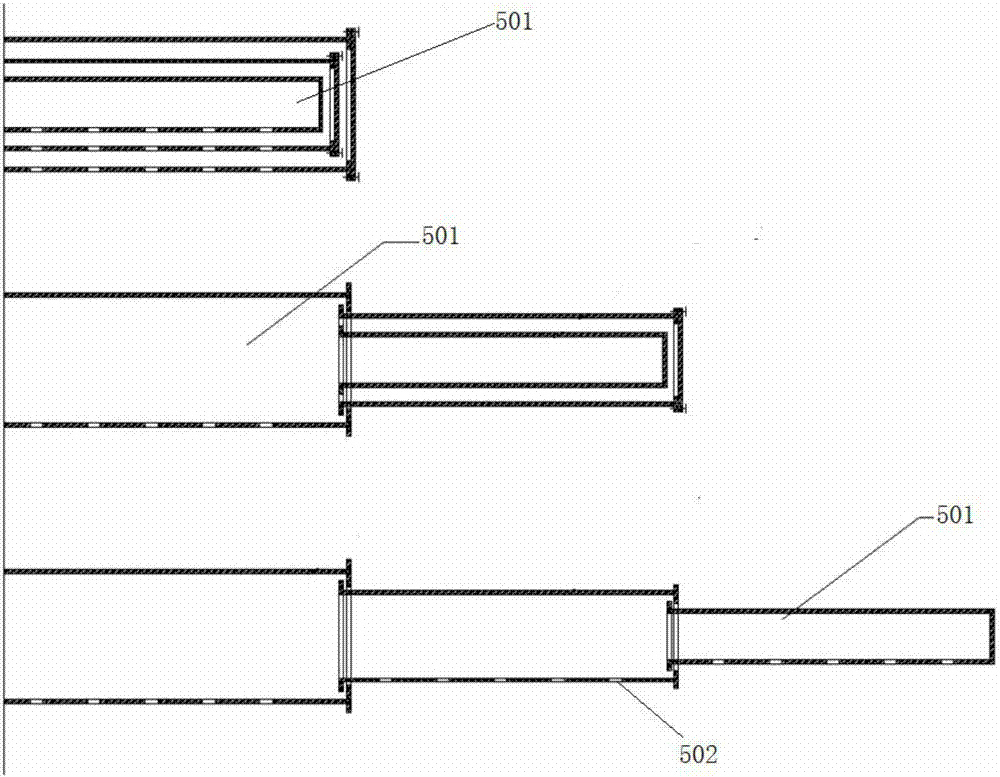

[0084] A multi-degree-of-freedom blowing device for sintering includes a pillar 1, a support 2, a fuel delivery pipe 3, a fuel branch pipe 4, a blowing pipe 5 and a sintering machine 8. The pillars 1 are located on both sides of the sintering machine 8, and the support 2 is arranged above the sintering machine. The bracket 2 is arranged on the pillar 1 . The fuel delivery pipe 3 is connected to the fuel branch pipe 4 . The injection pipe 5 is connected to the fuel branch pipe 4 . The blowing pipe 5 is arranged on the support 2 . The blowing pipe 5 is a two-section blowing sleeve 501 . The blowing sleeve 501 adopts the structure of a telescopic sleeve. The blowing sleeve 501 is provided with blowing holes 502 .

[0085] One side of the fuel delivery pipe 3 is provided with 20 fuel branch pipes 4 . One side of the fuel branch pipe 4 is provided with 10 injection pipes 5 .

Embodiment 2

[0087] Embodiment 1 is repeated, except that the fuel branch pipe 4 and the fuel delivery pipe 3 are connected through a metal hose 401 . The lower end of the pillar 1 is provided with a traveling wheel 103 .

Embodiment 3

[0089] Embodiment 1 is repeated, except that the fuel branch pipe 4 and the fuel delivery pipe 3 are connected through a metal hose 401 . The pillar 1 includes a fixed support leg 101 and a lifting device 102 . The lifting device 102 is an electric screw type lifting device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com