Fault fracture zone tunnel-section treatment structure in TBM construction tunnel

A broken zone and tunnel technology, which is applied in the field of poor geological conditions of TBM construction tunnels, can solve the problems of large excavation, delayed construction period, long construction period, etc. The effect of force and torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below by accompanying drawing.

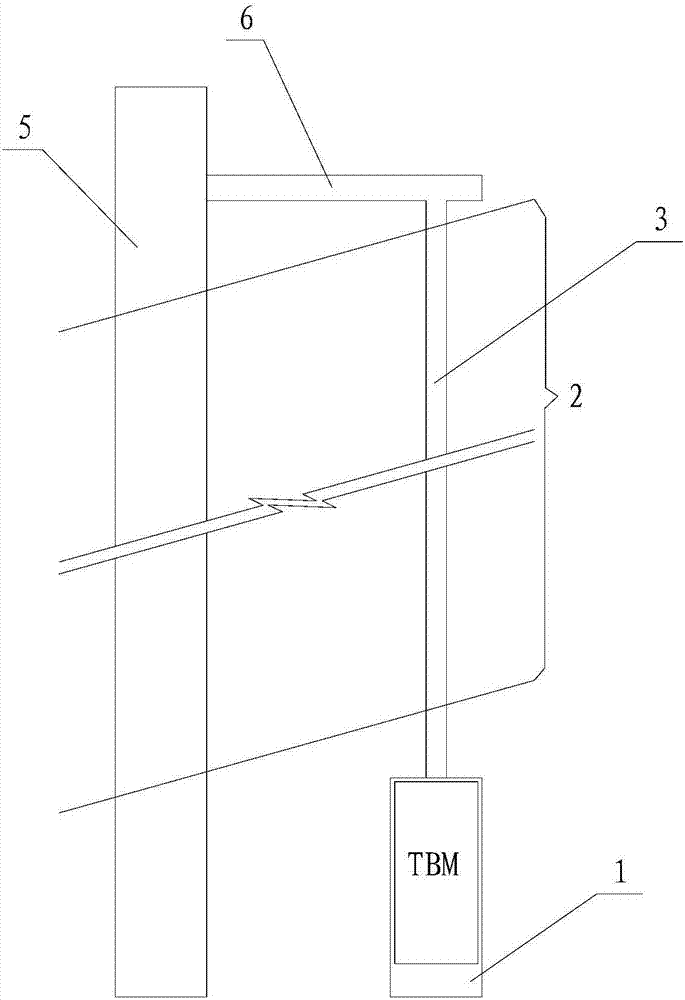

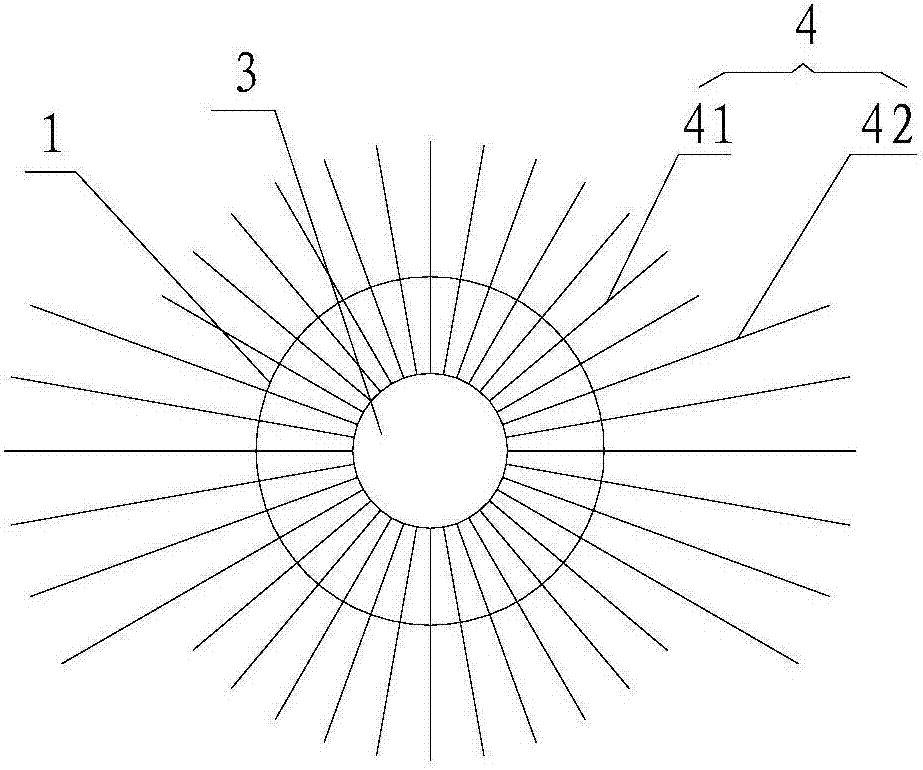

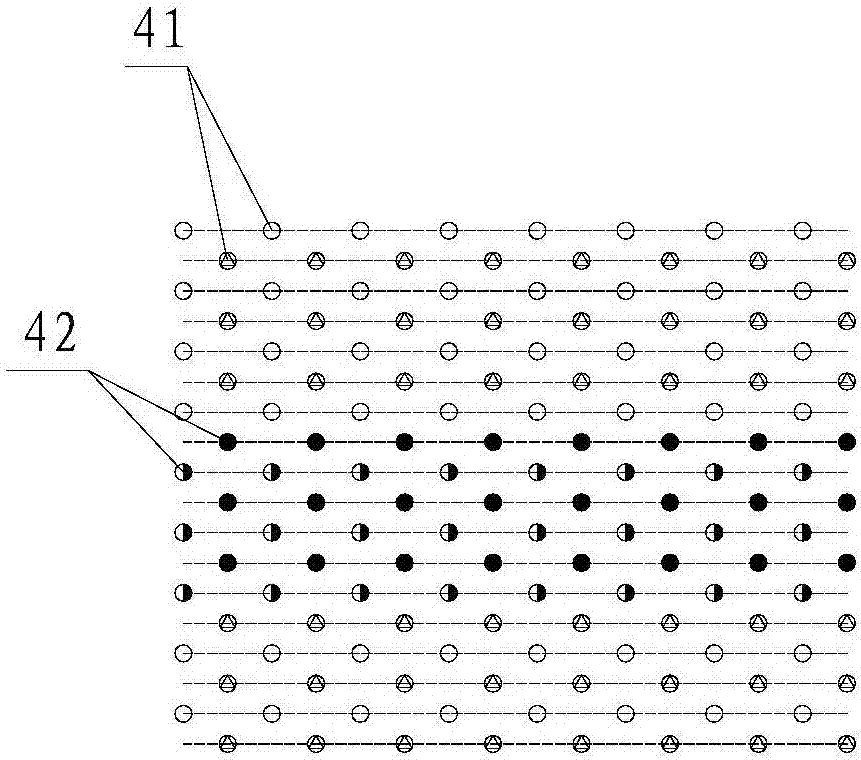

[0026] Such as figure 1 , figure 2 As shown, the present invention includes a tunnel 1 and a fault fracture zone 2 located in front of the face of the tunnel. A pilot tunnel 3 is provided in the center of the tunnel face. The pilot tunnel 3 is coaxial with the tunnel 1 and runs through the entire fault fracture zone 2. The surrounding rock of the pilot tunnel 3 is supported by shotcrete, and a plurality of grouting boreholes 4 are arranged on the surrounding rock. The end of the grouting boreholes 4 away from the center of the tunnel 1 exceeds the periphery of the tunnel 1 . Grouting material is provided in the borehole 4 . The diameter of the pilot tunnel 3 is generally set at 4-5m, and the drilling and blasting method can be used for excavation. The grouting hole 4 is set on the surrounding rock of the pilot tunnel 3, and the purpose of filling the grouting hole 4 with grouting material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com