Hollow thread-shaped drill bit suitable for super long screw pile cast-in-situ construction in soft foundation and using method of hollow thread-shaped drill bit

A soft foundation, threaded drill technology, applied in drill bits, infrastructure engineering, drill pipes, etc., can solve the problems of long length, the length of screw piles cannot be lengthened, and the construction of super-long screw piles cannot be realized, and the effect of ensuring construction quality is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

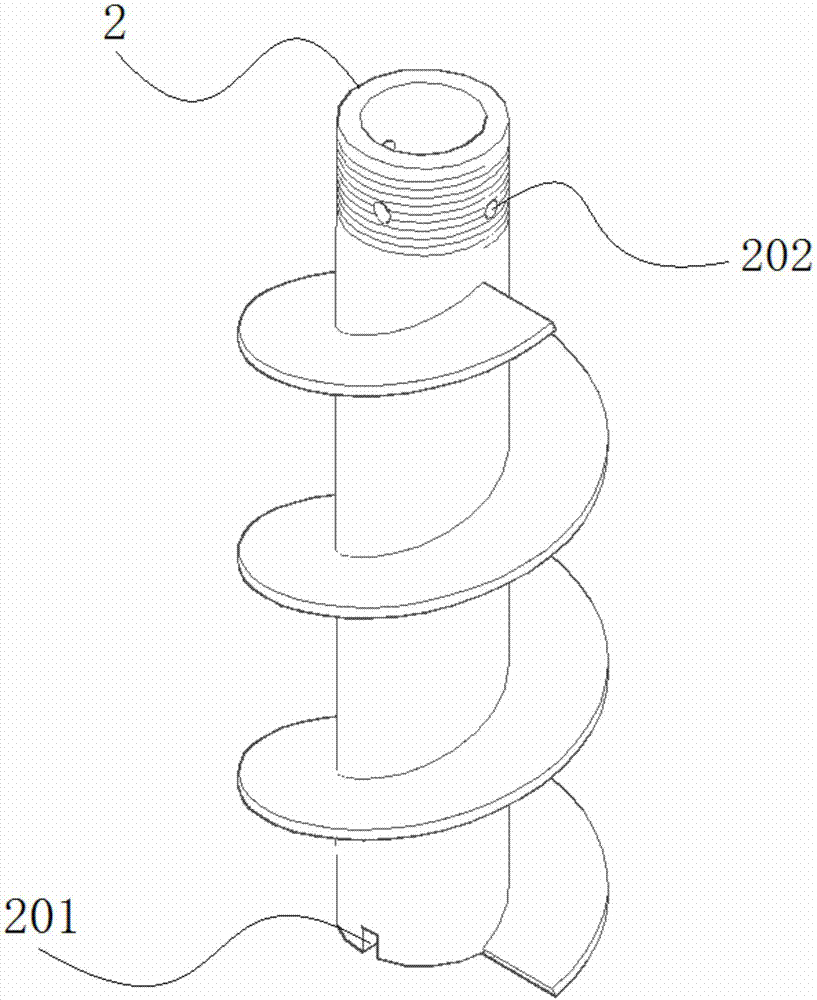

[0044] This embodiment discloses a hollow threaded drill bit suitable for the construction of cast-in-place super-long screw piles on soft ground, including: spud can 1, hollow threaded drill pipe I2, segmented hollow threaded drill pipe II3, annular steel hoop 4 and pin 5.

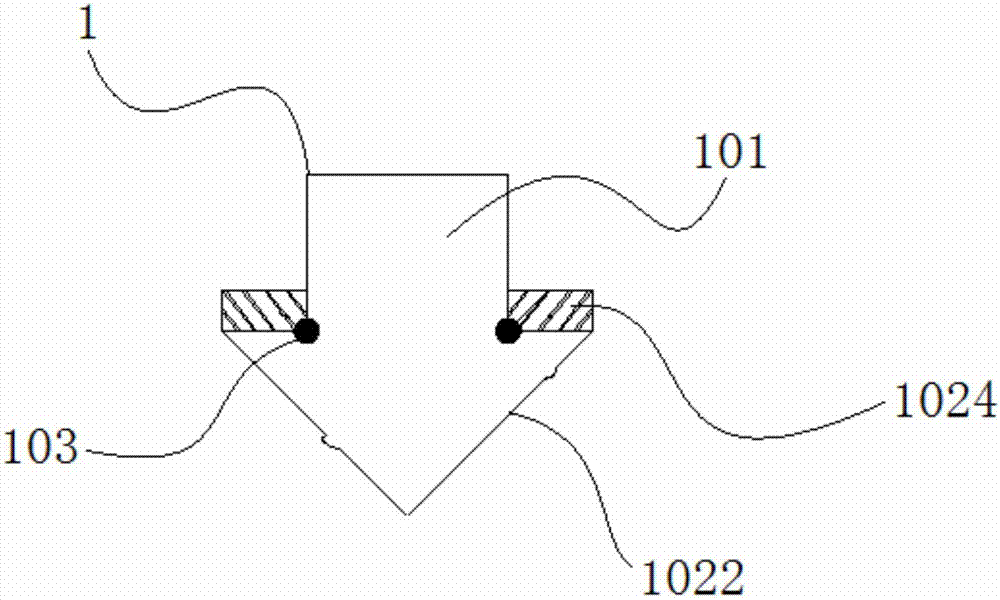

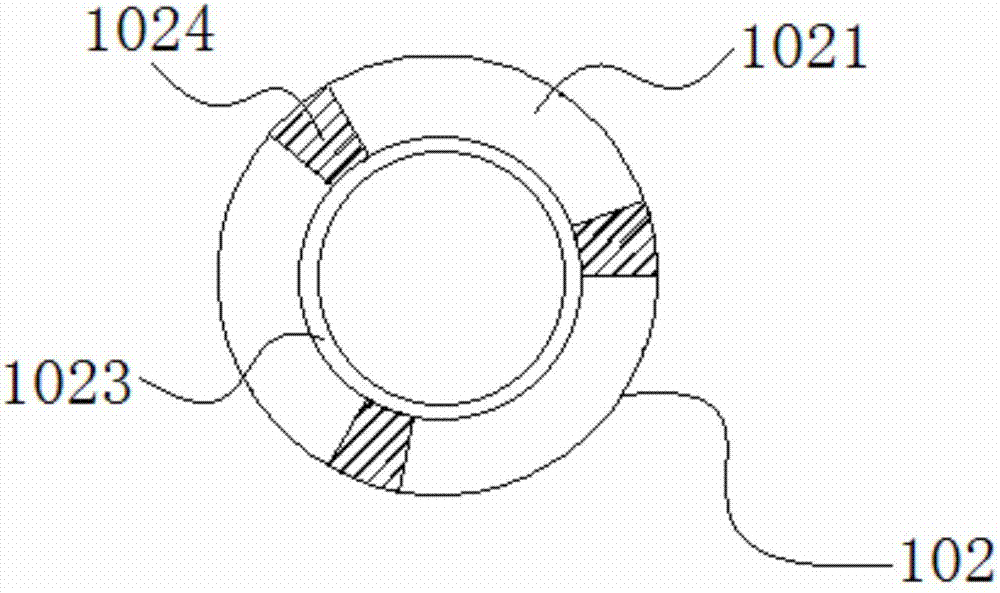

[0045] see figure 1 with figure 2 , the spud boot 1 includes a boot body 101 and a boot toe 102 arranged at the bottom of the boot body 101 . The boot body 101 is a cylinder. The toe 102 is a cone as a whole. The base of this cone faces up and the apex faces down. The boot toe 102 includes a top surface 1021 , which is the bottom surface of the cone, and a side surface 1022 , which is the side surface of the cone. The top surface 1021 is attached to the bottom surface of the boot body 101 . The boot toe 102 is provided with an annular groove 1023 at the intersection of the top surface 1021 and the boot body 101 . A sealing ring 103 is installed in the annular groove 1023 . Three protrusions 1024 a...

Embodiment 2

[0052] This embodiment discloses a method for using the hollow threaded drill bit suitable for the construction of super-long screw piles on soft foundations described in Embodiment 1, including the following steps:

[0053] 1) Fix the spud shoe 1 at the pile position.

[0054] 2) Install the hollow threaded drill pipe I2. Wherein, the lower end of the hollow threaded drill rod I2 is connected with the spud can 1, and the upper end is connected with the rotary driving part of the drilling rig.

[0055] 3) The hollow threaded drill pipe I2 and the spud can 1 are drilled into the ground by the rotational driving force and vertical pressure of the drilling rig.

[0056] 4) When all or most of the hollow threaded drill pipe I2 is drilled into the ground, and the depth of the drilled hole has not reached the designed length of the screw pile, remove the connection between the upper end of the hollow threaded drill pipe I2 and the rotary driving part of the drilling rig. And use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com