Glove weaving device

A glove and machine head technology, which is applied to weft knitting, knitting, and circular knitting machines with individual moving needles. It can solve the problems of difficult assembly, high labor costs, and complicated operations, and achieve increased knitting speed. , Reduce labor costs, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

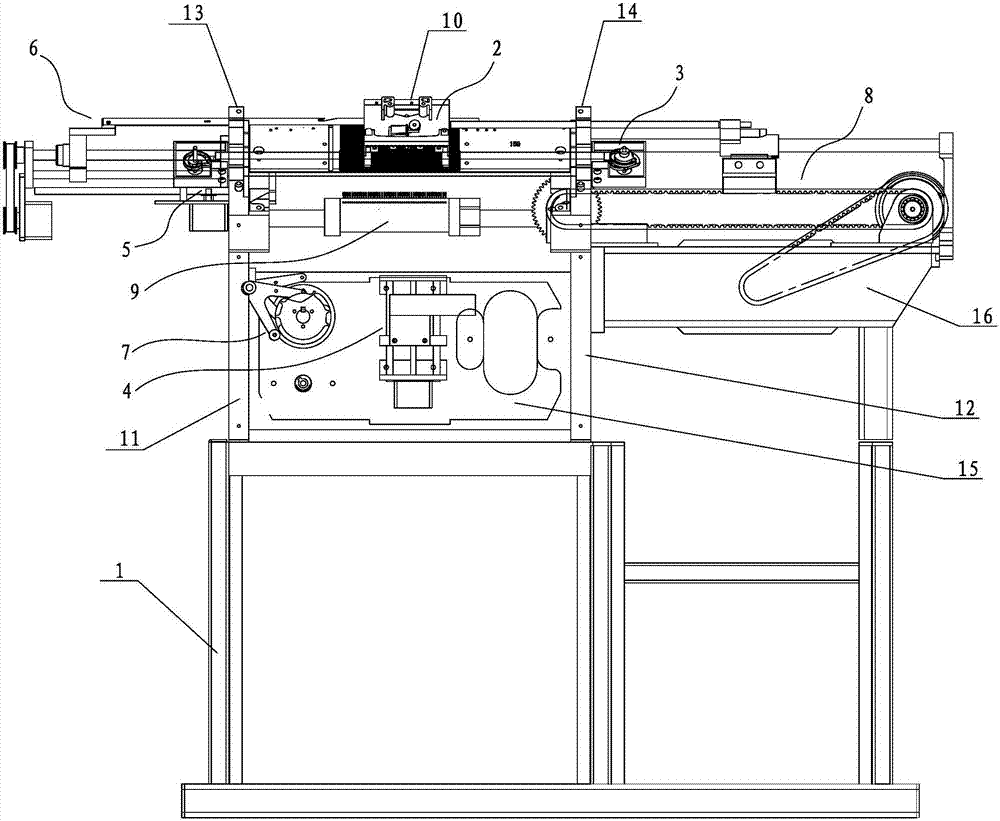

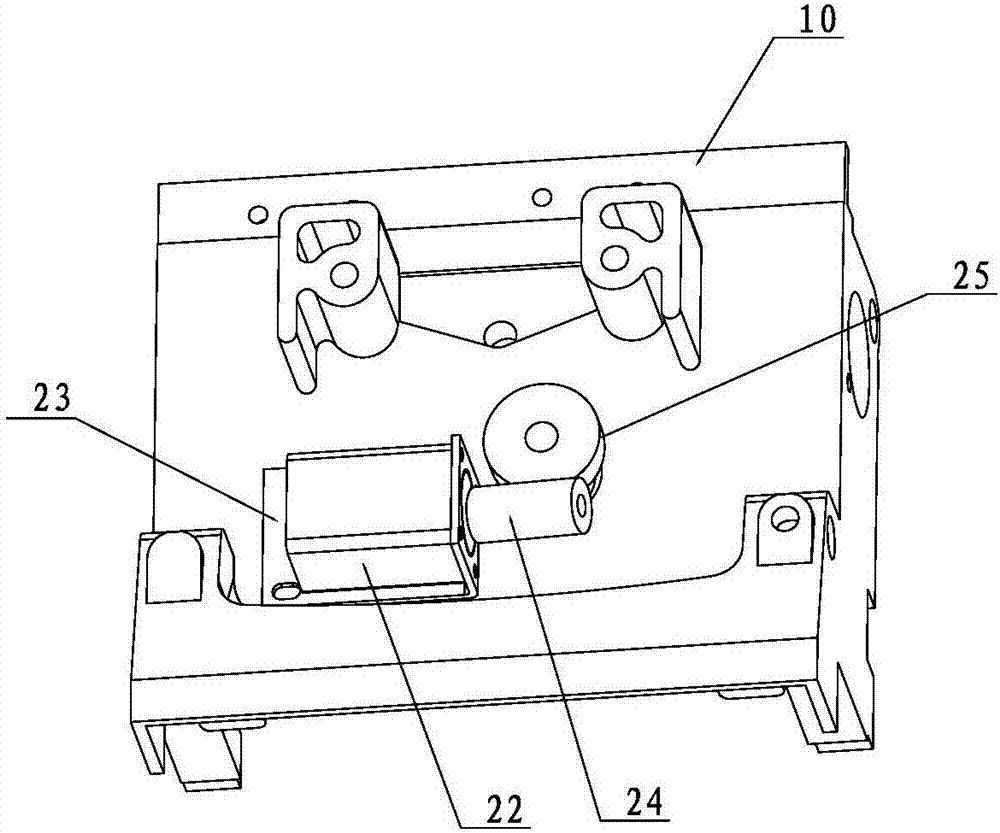

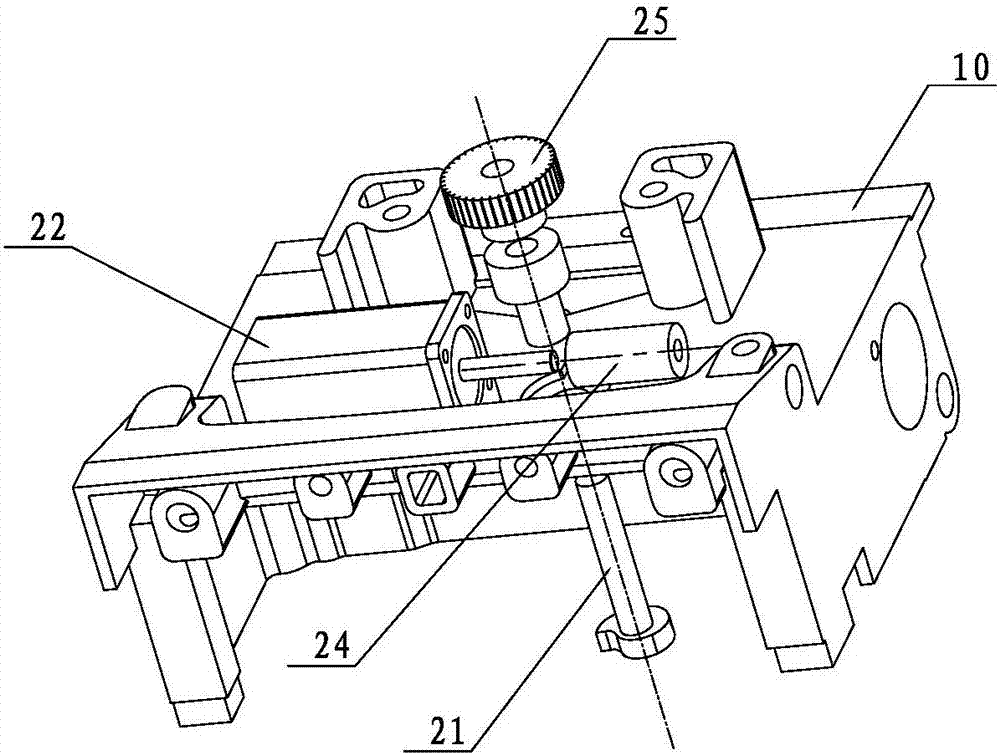

[0038] Such asfigure 1 As shown, a glove knitting device includes a frame 1, an automatic density adjustment mechanism 2 arranged on the frame 1, a push rod control mechanism 3, a glove length detection mechanism 4, a scissors transmission mechanism 5, a fork knife transmission mechanism 6, Cam transmission mechanism 7, machine head transmission mechanism 8, needle selection mechanism 9, and a control unit for controlling the above-mentioned various mechanisms; wherein, a left wall panel 11 and a right wall panel 12 are respectively provided on the left and right sides of the top of the frame 1 , A left corner wallboard 13 and a right corner wallboard 14 are arranged above the left wallboard 11 and the right wallboard 12 respectively. Generally, the glove knitting device has two sets of knitting systems, front and back, and knits both sides of the glove at the same time. Each knitting system is equipped with its own machine head 10, automatic density adjustment mechanism 2, ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com