Selenium-rich spray solution as well as preparation method and application thereof

A technology for spraying liquid and enriching selenium, which is applied in the field of plant nutrient solution, can solve the problems of high production cost of selenium-containing fertilizer, human toxicity, poor crop effect, etc., so as to improve seed setting rate and stress resistance, increase yield, and increase nutritional components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

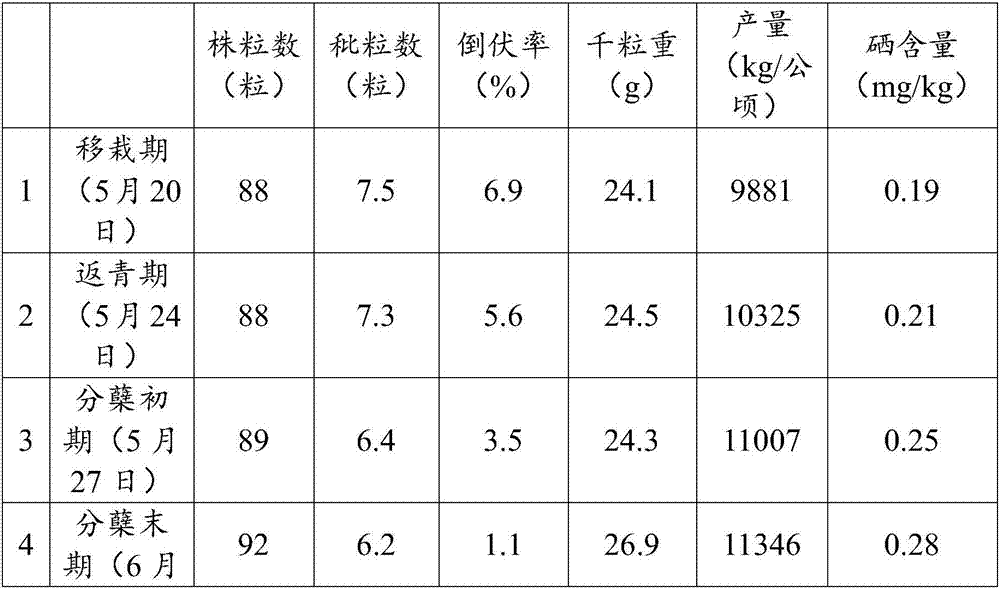

Examples

preparation example Construction

[0045] Optionally, in the selenium-enriched spray liquid provided by the embodiment of the present invention, the selenium content in the selenium-enriched black fungus defatted dry powder is ≥0.15 mg / kg; preferably, the preparation method of the selenium-enriched black fungus defatted dry powder comprises the following steps: The selenium black fungus fruit body is washed, dried, ground and sieved, then degreased with an organic solvent, centrifuged to discard the supernatant, and then dried to obtain the selenium-enriched black fungus defatted dry powder.

[0046] Preferably, the drying temperatures are independently 50-60°C; alternatively, the drying temperatures are independently typical but not limited to 50°C, 51°C, 52°C, 53°C, 54°C, 55°C, 56°C °C, 57°C, 58°C, 59°C or 60°C.

[0047] Preferably, the sieve mesh is 60-100 mesh; alternatively, the sieve mesh is typically but not limited to 60, 80 or 100 mesh.

[0048] Preferably, the organic solvent is acetone, the degreasi...

Embodiment 1

[0072] A selenium-enriched spray solution, in terms of volume percentage, mainly consists of the following components: 0.6% of organic selenium element extract, and the balance is water;

[0073] In terms of parts by mass, the organic selenium element extract is mainly made of the following raw materials: 1 part of selenium-enriched corn flour and 10 parts of double distilled water.

[0074] The preparation method of the above-mentioned selenium-enriched spray liquid comprises the following steps: (1) mixing the selenium-enriched corn flour and double-distilled water in the formula amount, stirring at 25° C. for 20 minutes at a stirring speed of 1000 rpm, and centrifuging at 3000 rpm for 20 minutes to obtain the supernatant solution, then add double distilled water to the residue, stir and repeat the extraction for 2 times, and combine the supernatant obtained 3 times to obtain the organic selenium element extract; (2) mix the organic selenium element extract with the formula a...

Embodiment 2

[0076] A selenium-enriched spray solution, in terms of volume percentage, mainly consists of the following components: 1.2% of organic selenium element extract, and the balance is water;

[0077] In terms of parts by mass, the organic selenium element extract is mainly made of the following raw materials: 3 parts of selenium-enriched malt powder and 15 parts of double distilled water.

[0078] The preparation method of the above-mentioned selenium-enriched spray liquid comprises the following steps: (1) mixing the selenium-enriched malt powder and double distilled water in the formula amount, stirring at 20° C. for 30 minutes at a stirring speed of 800 rpm, and centrifuging at 5000 rpm for 10 minutes to obtain the supernatant solution, then add double distilled water to the residue, stir and repeat the extraction for 2 times, and combine the supernatant obtained 3 times to obtain the organic selenium element extract; (2) mix the organic selenium element extract with the formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com