Small tea leaf three-piece can

A three-piece can and tea technology, which is applied in the field of small tea three-piece cans, can solve the problems of lack of good guarantee of sealing and safety, backward production technology, low production efficiency, etc., so as to improve food safety performance and material quality. The effect of high utilization rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solutions in the embodiments of the present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

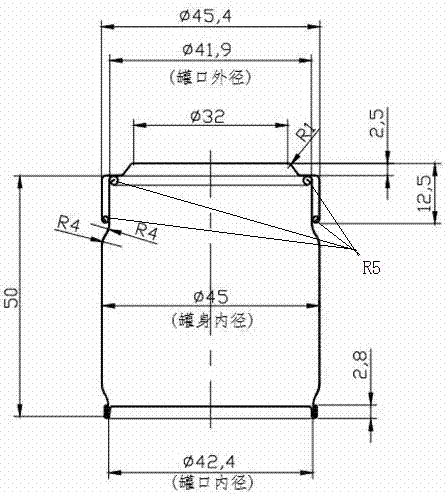

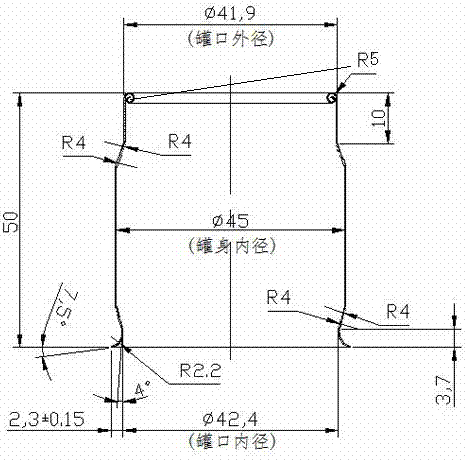

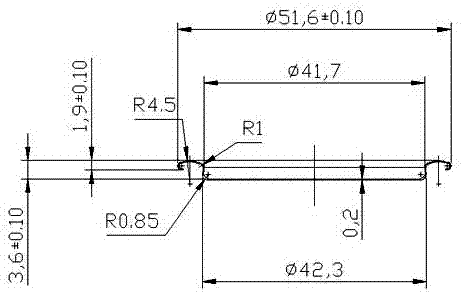

[0010] The small three-piece tea can of the present invention is composed of a can body, a bottom cover and an upper cover, and is made of tinplate material. Can body such as figure 2 As shown, the can body is a hollow cylinder surrounded by tinplate material, the height of the can is 50mm, the diameter of the can body is 45mm, and the tinplate material on the top of the can mouth is rolled into a circular R5 cross section (such figure 2 ), the upper part of the tank mouth is necked, the height of the upper necked neck is 10mm, the diameter of the upper necked neck is 41.9mm, and there is a connecting arc R4 between the upper necked neck and the tank body (such as figure 2 ), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com