Radiofrequency ablation probe and manufacturing method thereof

A technique for radiofrequency ablation and catheter ablation, which is applied in the field of radiofrequency ablation probes and its preparation, and can solve problems such as poor function and performance, unstable preparation quality, and lack of specific needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

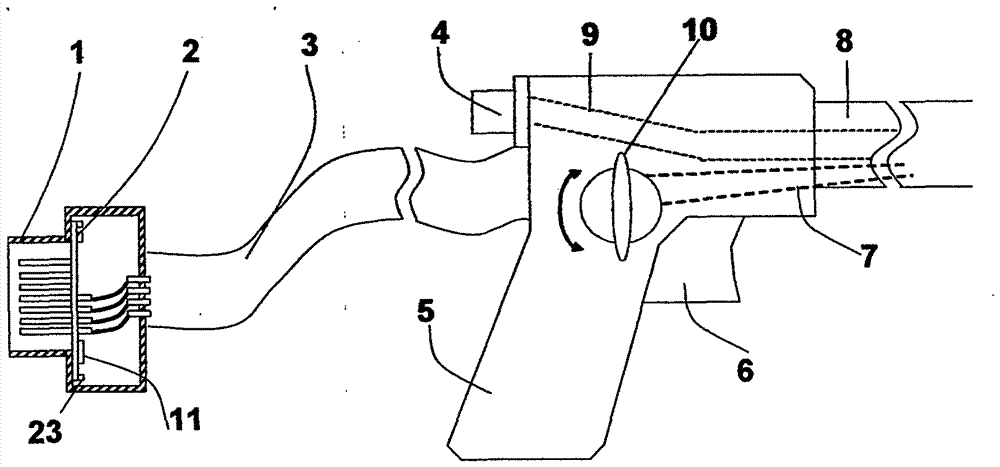

[0022] figure 1 It is a schematic diagram of the connection cable assembly and the handle part of the embodiment of the present invention. The connection cable assembly includes a radio frequency connection connector 1 , a connector embedded circuit 2 and a cable 3 . The radio frequency connection joint 1 is used to connect the radio frequency power connection line and the thermocouple connection line to the radio frequency ablation generator; the proximal end of the cable 3 is connected to the radio frequency connection joint, and the far end is connected to the handle, and the material of the handle shell is ABS Or PC, there is a cable fixing structure, a button switch PCB, and a guide tube inlet. The handle has a hand-held structure 5. There is a guide tube opening 4 in the middle for inserting a guide wire or injecting saline or medicine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com