Robot-based wiring harness terminal automatic plugging device and wiring harness terminal plugging method thereof

A technology of robots and plug-in, applied in the assembly/disassembly of contacts, vehicle connectors, etc., to save human resource costs, ensure accuracy and reliability, and ensure the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

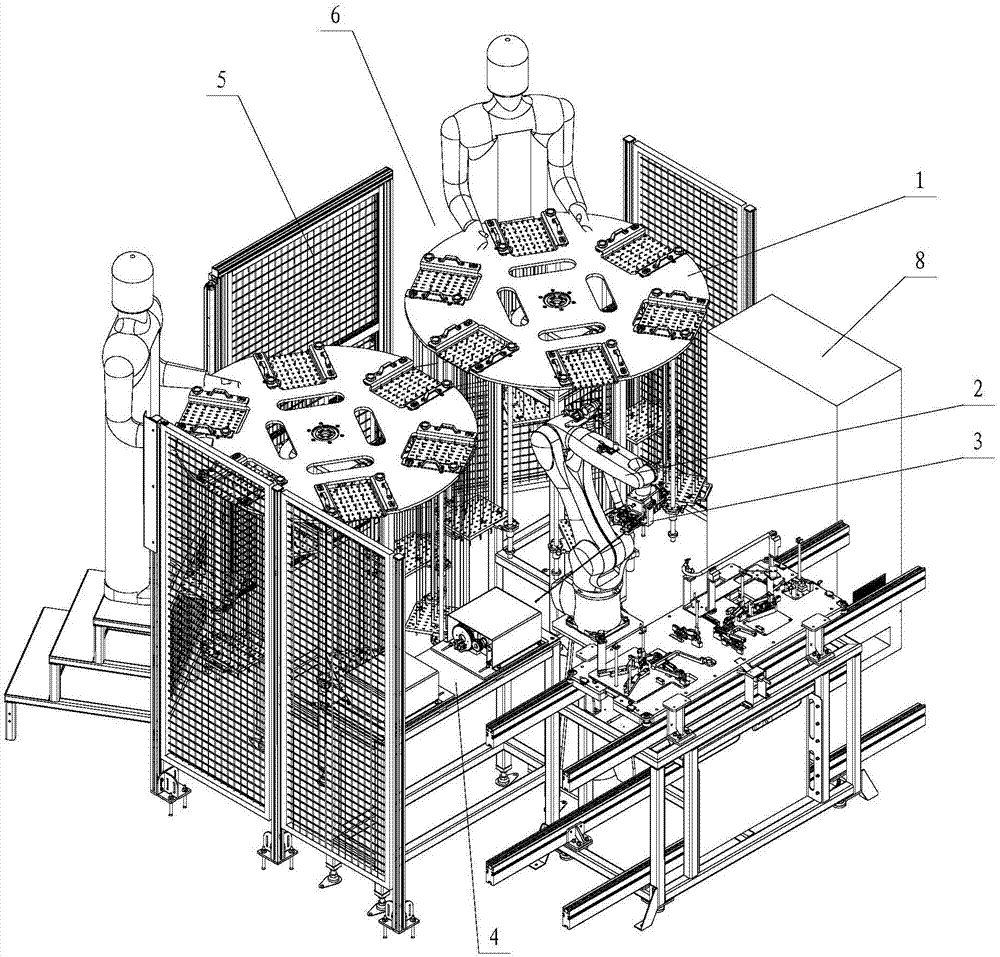

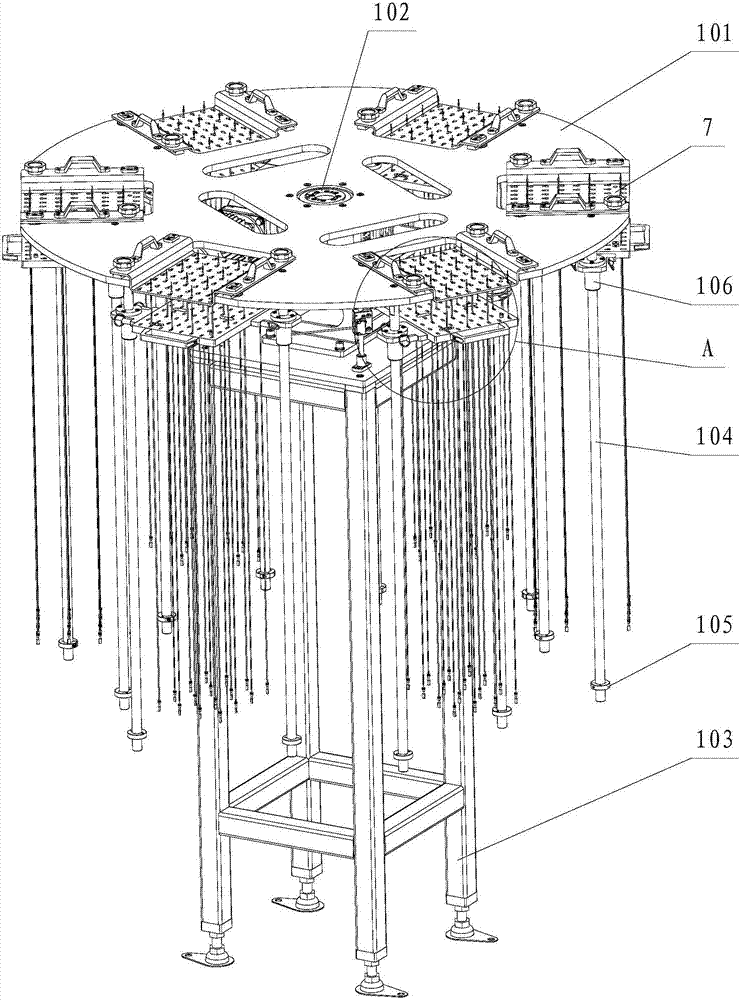

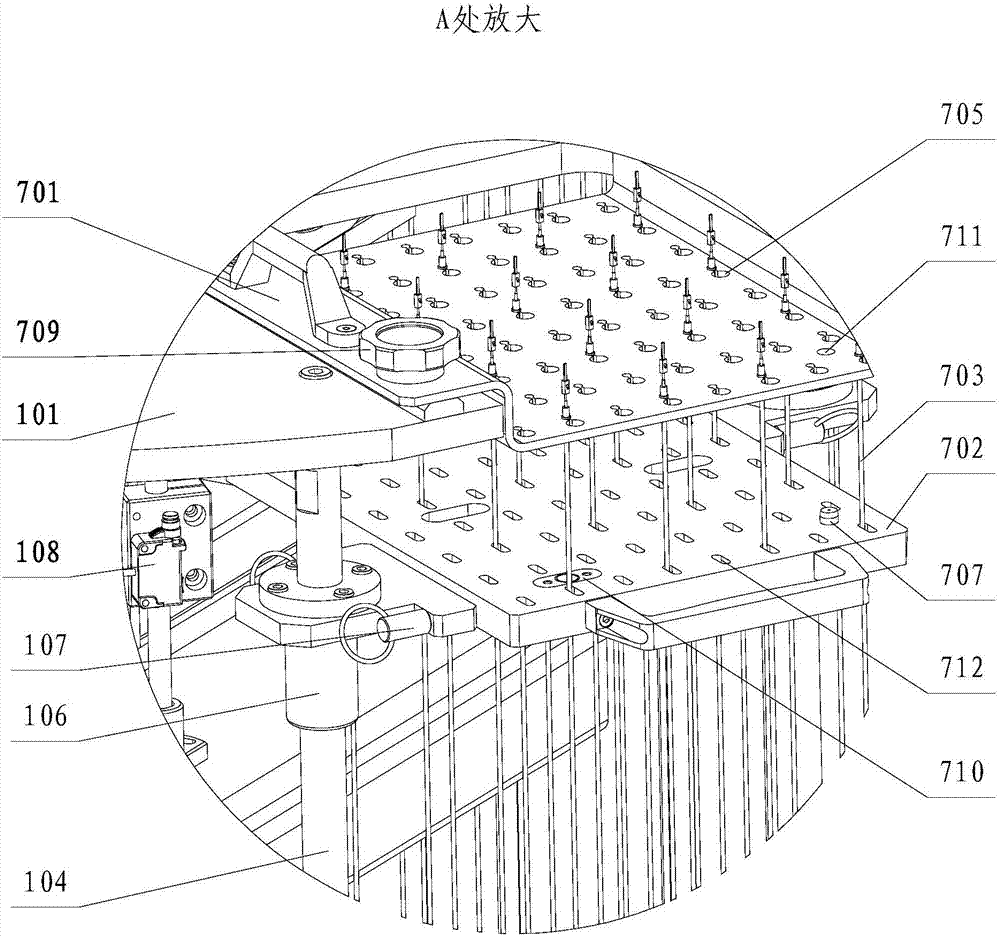

[0037] like Figure 1~5As shown, the device of the present invention includes a feeding rotary mechanism 1, a multi-axis linkage robot 2, a wire insertion and take-up gripper 3 and a visual verification workbench 4, wherein the feeding rotary mechanism 1 includes a mounting frame A103, installed on the mounting frame The divider 102 on A103, the rotary platform 101 driven and rotated by the divider 102, and the plurality of tray assemblies 7 evenly distributed on the rotary platform 101 along the circumferential direction, the feeding rotary mechanism 1 of this embodiment is two, arranged side by side , each feeding rotary mechanism 1 is driven by a sextant divider 102. A rotary platform 101 with six tray assemblies 7 is manually loaded at one station, and the multi-axis linkage robot 2 is at the feeding station 6. The material is taken from the opposite sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com