Method for adjusting lubricating oil level in engine lubricating system

A lubricating system and lubricating oil technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve problems such as impact and poor engine performance, and achieve the effects of reducing emissions, reducing friction, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

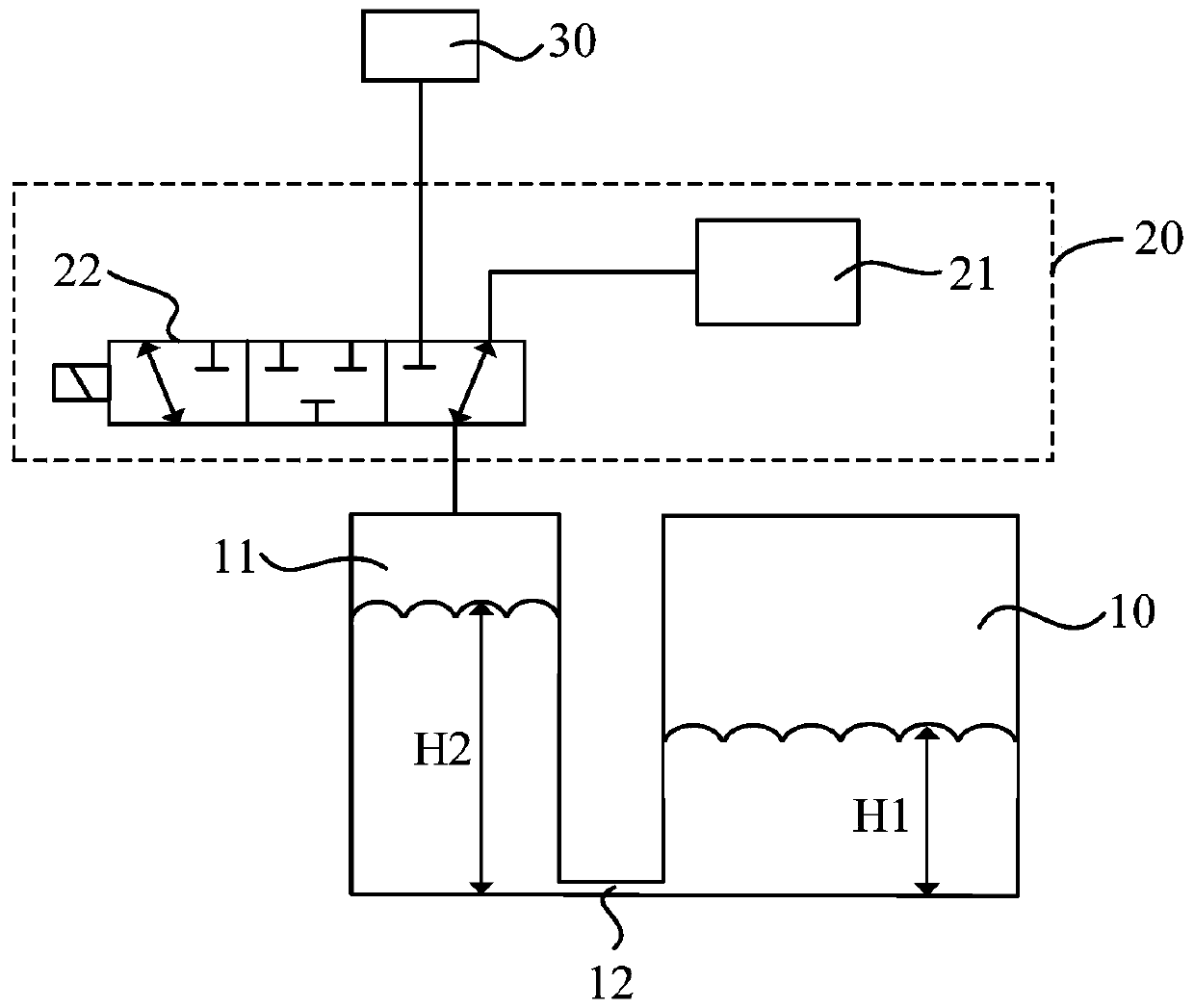

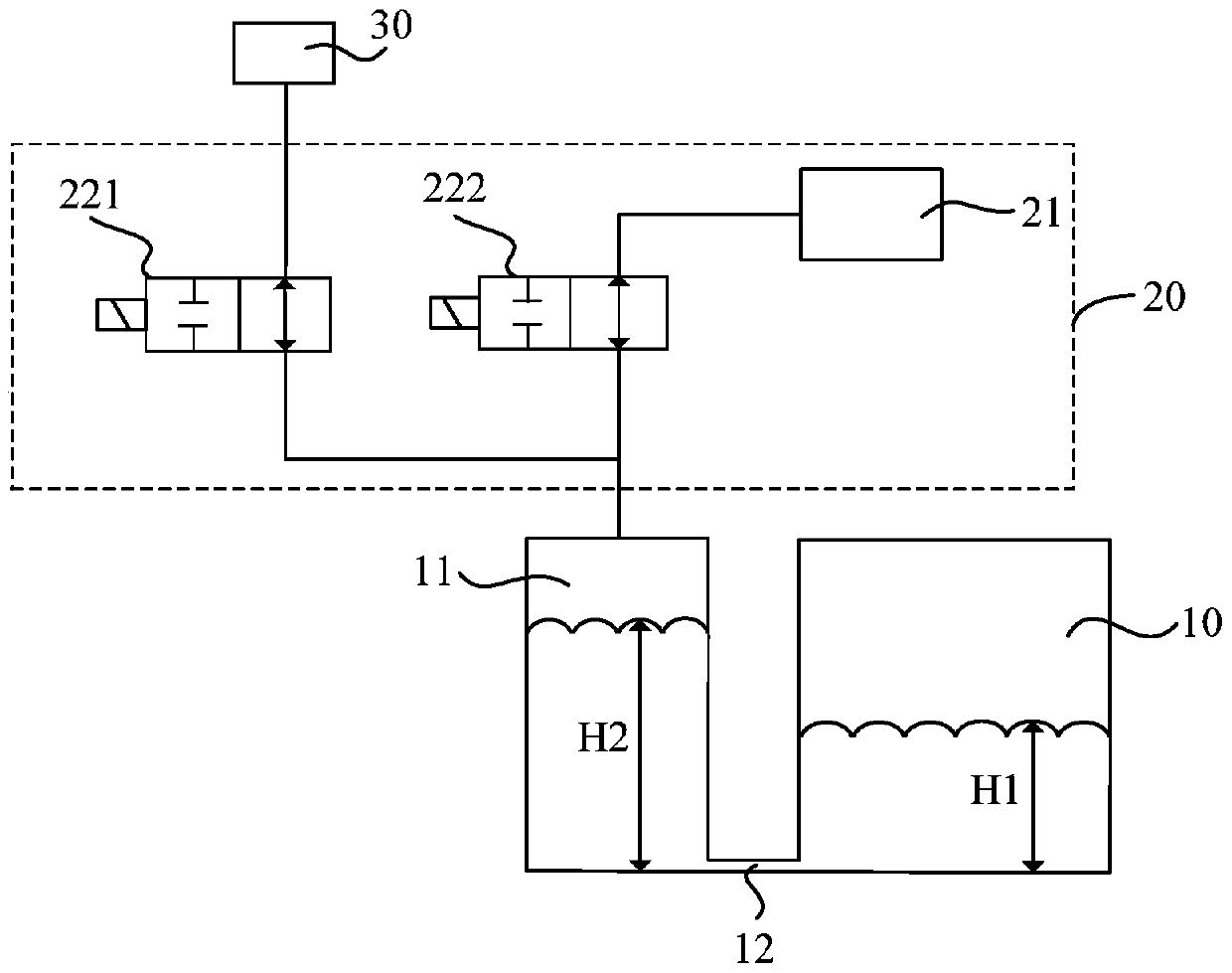

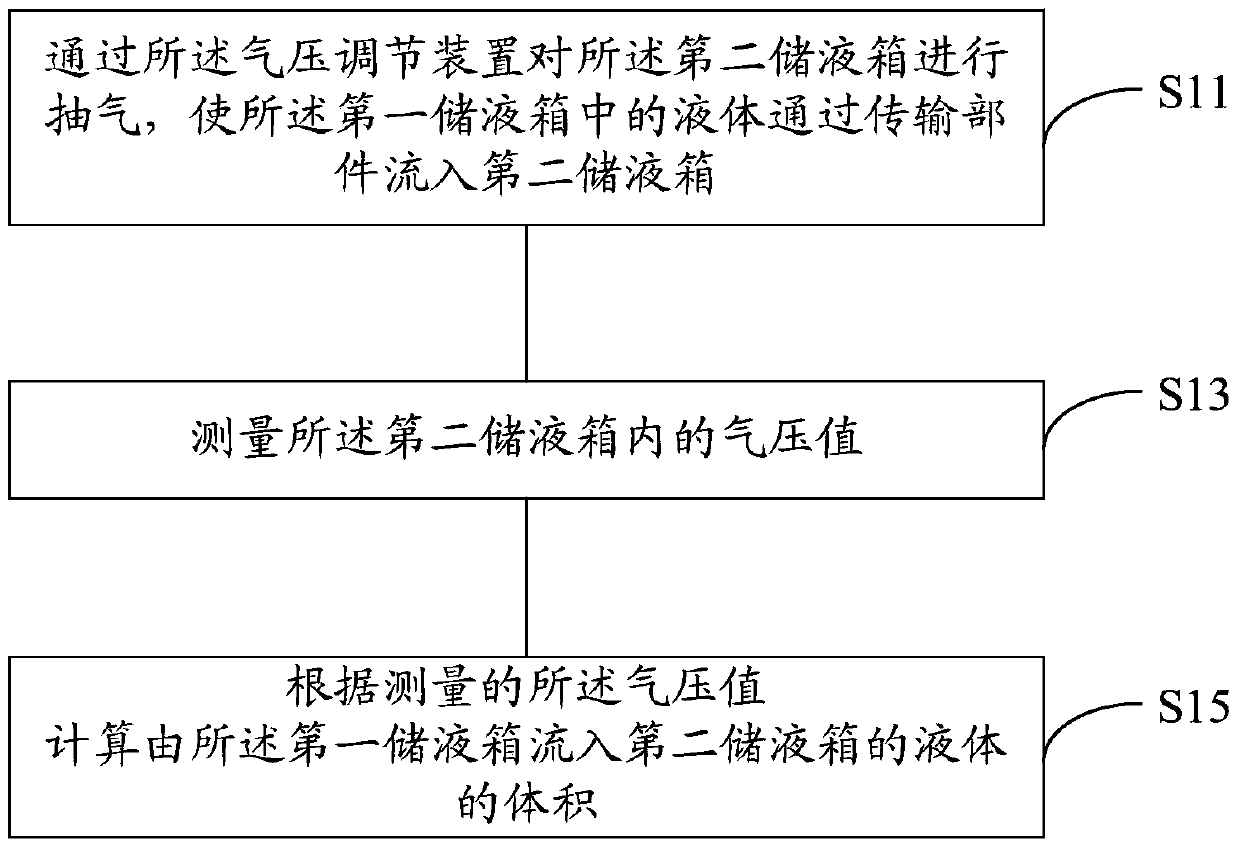

Image

Examples

Embodiment Construction

[0039] As described in the background technology, although there are also methods to increase the temperature rise rate of engine lubricating oil in the prior art, such as by designing the oil pan of the engine as an oil separation pool to achieve this purpose, there is a baffle in the oil separation pool, which can Most of the cold oil is separated from the hot oil that the engine needs to draw. However, the research of the inventors has found that this structure of the oil separation pool faces a series of problems: firstly, the effect of isolating the cold engine oil and the hot engine oil through the oil separation pool is not good. On the one hand, the oil returned from the crankcase will enter each sub-pool of the oil separation pool, resulting in a small amount of cold engine oil mixed with hot engine oil; Transfer, poor insulation. Secondly, physical barriers such as baffles, valves, etc. set in the oil separation tank will reduce the ability of the engine oil to supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com