U-shaped steel bar bender

A steel bar bending and U-shaped technology, which is applied in the field of bending machines, can solve problems that affect the progress of the project, consume manpower and time, and achieve the effect of ensuring the progress of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

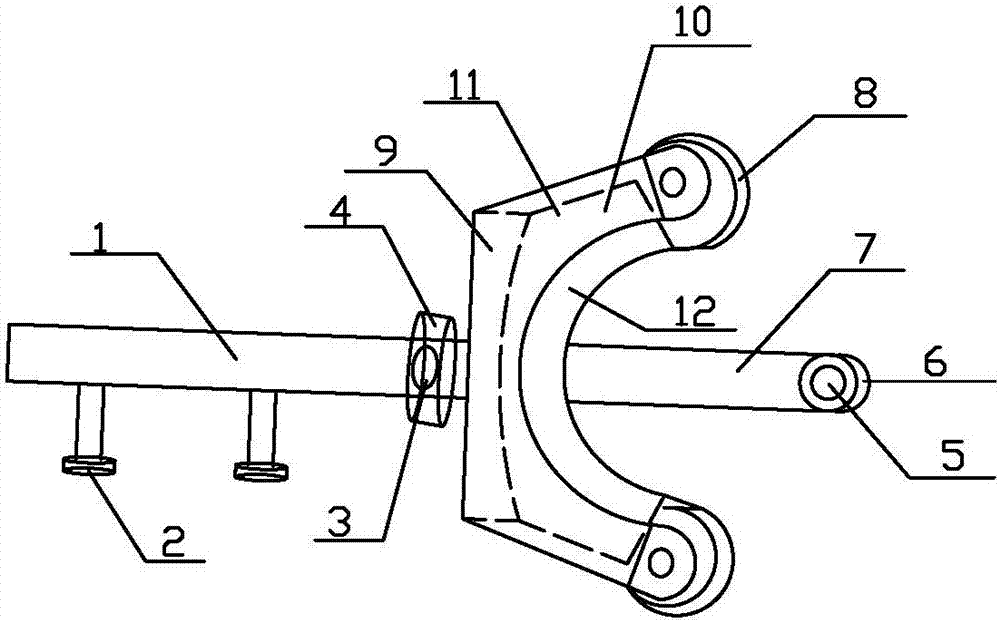

[0013] like figure 1 Shown, the technical scheme that the present invention takes is as follows:

[0014] U-shaped steel bar bending machine, including electric hydraulic oil pump 1, threaded joint 2, inner hexagonal screw 3, flange 4, bottom plate fixing column 5, concave wheel 6, fixed bottom plate 7, rolling wheel 8, U-shaped module 11; the U The U-shaped module 11 is composed of a support plate 9, an upper U-shaped plate 10, and a lower U-shaped plate 12. The support plate 9 is sandwiched between the upper U-shaped plate 10 and the lower U-shaped plate 12 to form a complete U-shaped module 11. The support plate 9 It is in the shape of a cuboid, the upper U-shaped plate 10 and the lower U-shaped plate 12 are parallel to each other, the distance between the upper U-shaped plate 10 and the lower U-shaped plate 12 is consistent with the width of the support plate 9, the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com