Method for adjusting high-efficiency region of permanent-magnet synchronous motor

A permanent magnet synchronous motor, high-efficiency technology, applied in the direction of synchronous machine, motor, high-speed motor control, etc., can solve the problems of undisclosed high-efficiency area adjustment method, unrealized high-efficiency area large-scale adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0121] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

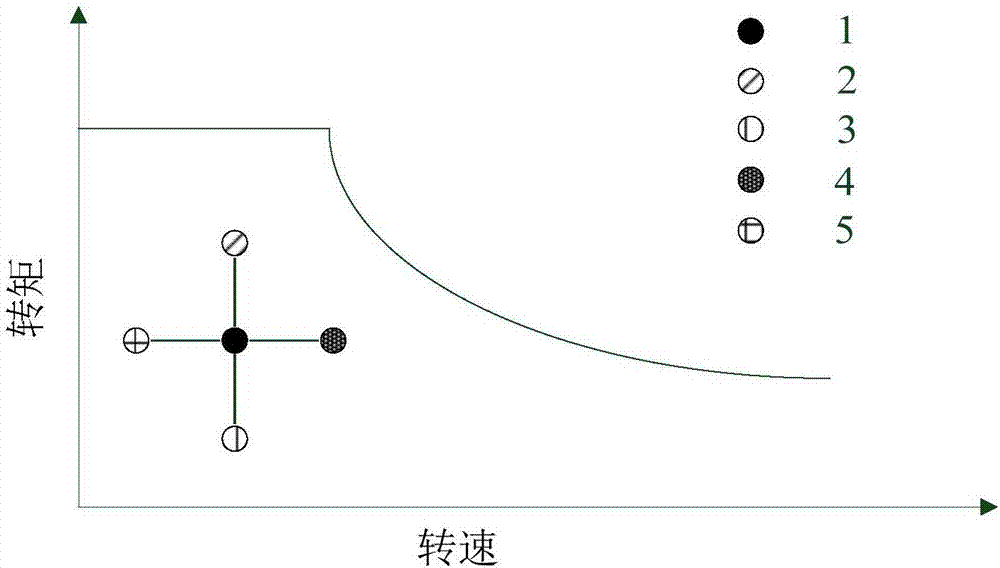

[0122] like figure 1 As shown, it is a relationship diagram between the midpoint "1" of the constant torque region of the permanent magnet motor and its up, down, right, left, and "2", "3", "4", and "5" in the present invention.

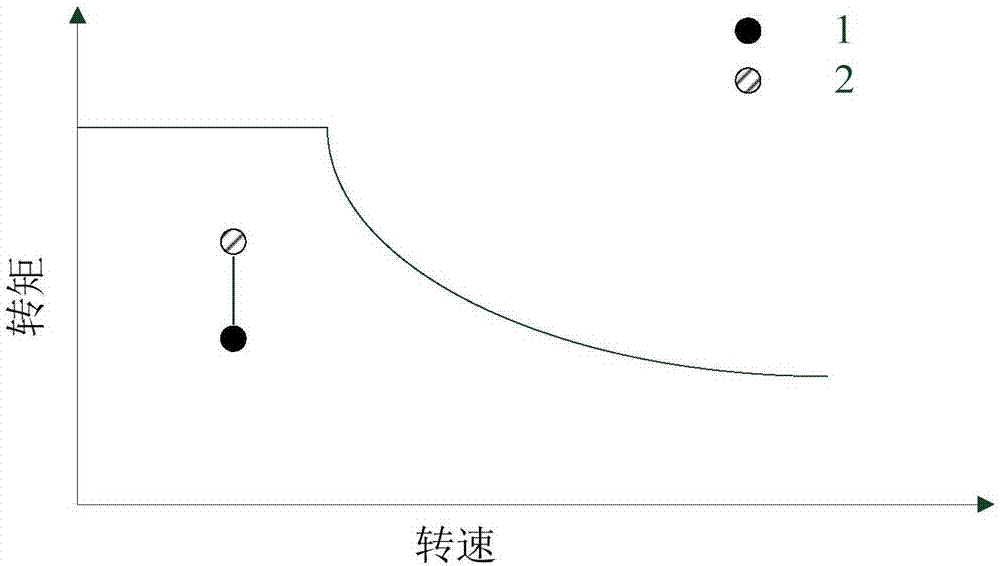

[0123] figure 2 It is the relationship diagram between the middle point "1" and the upper point "2" in the constant torque area in the present invention. According to the positional relationship between the two points in the constant torque area, the connection between the two points is listed as: n 2 =n 1 , I 2 =k 2 I 1 ; Calculate the relationship between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com