Steam cabinet control system

A technology for control systems and steam cabinets, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as easy negligence, and achieve superior performance, high thermal efficiency, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

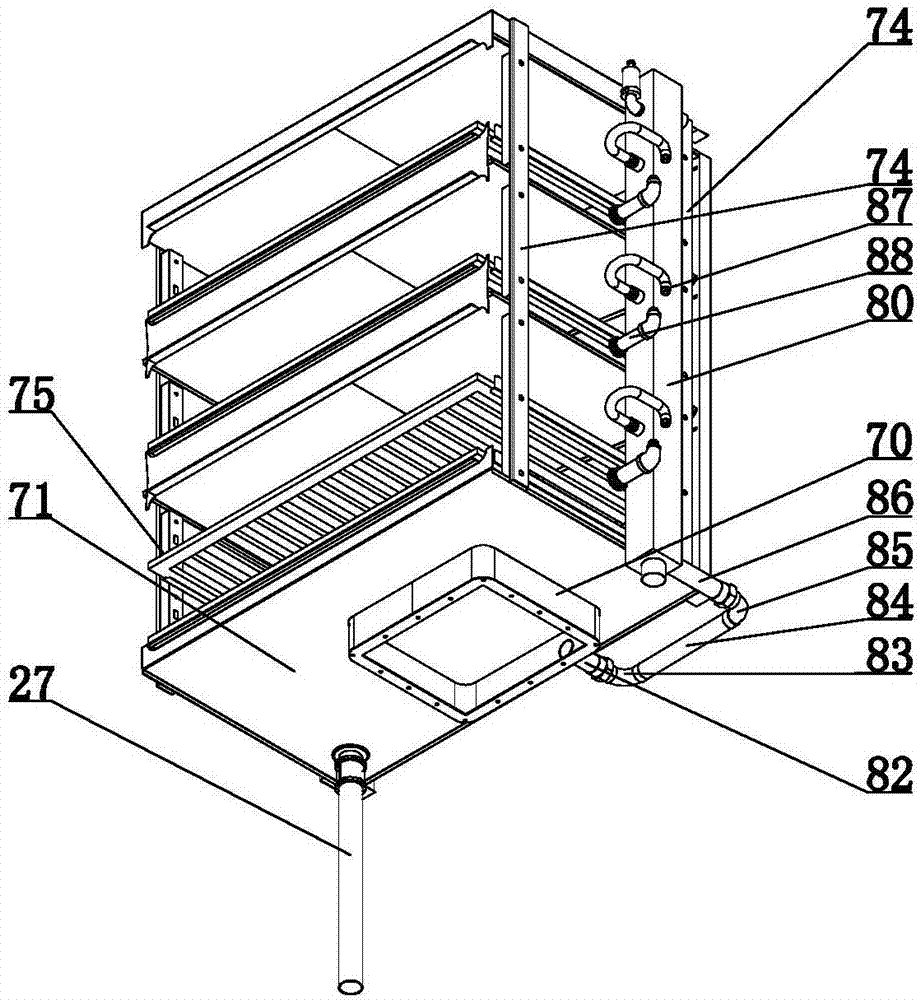

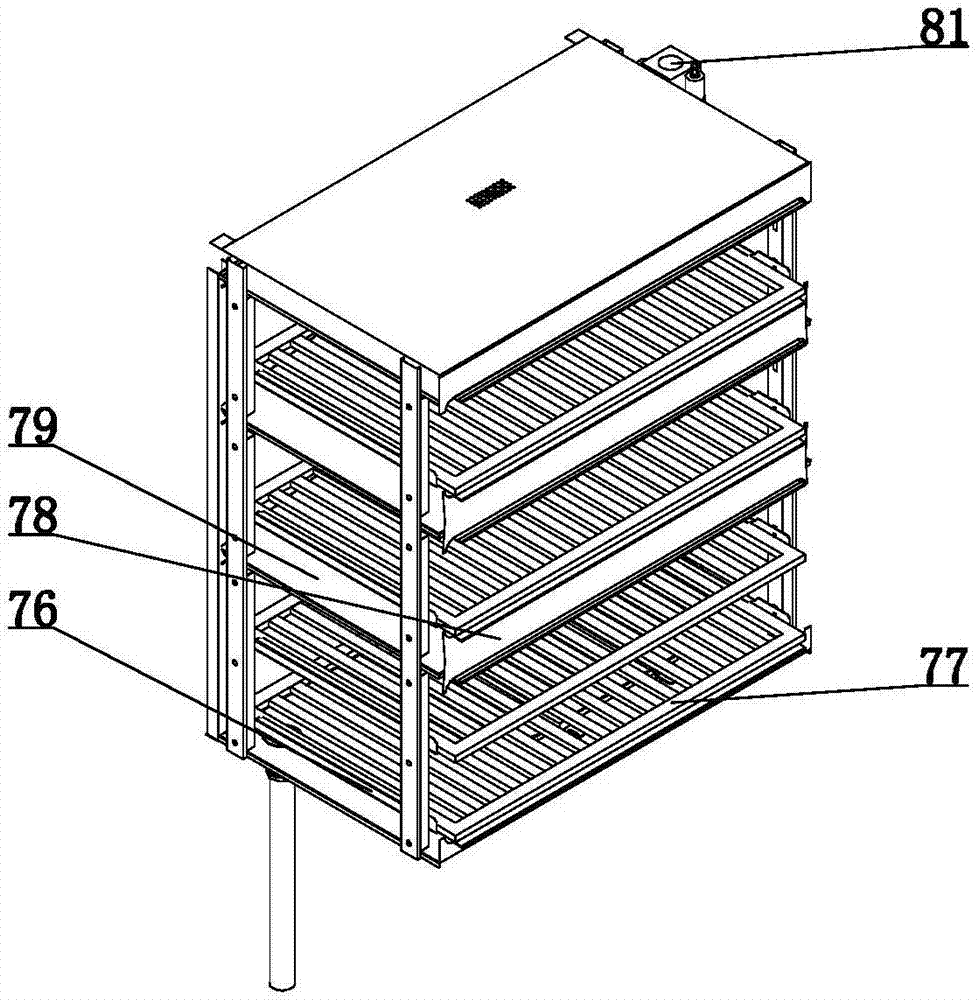

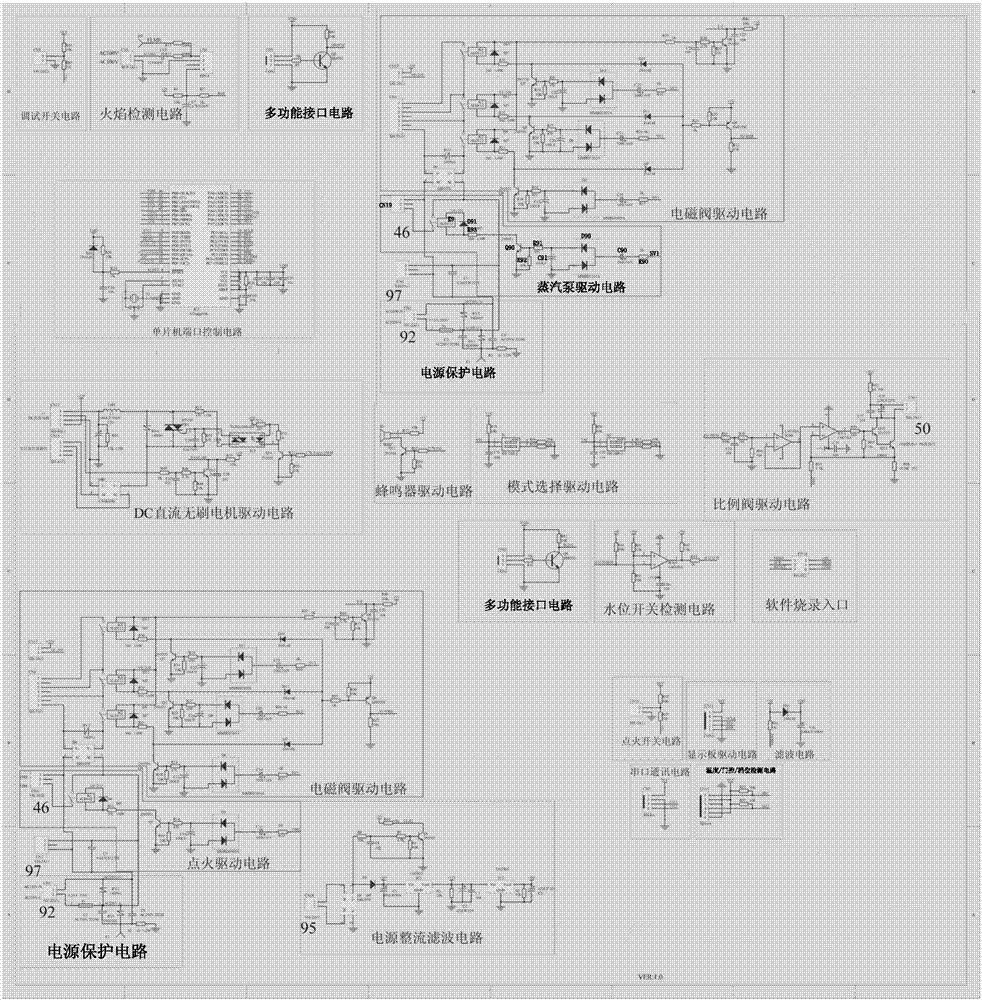

[0035] Such as figure 1 , 2, 3, 4, 5, 6, 7, 8, and 9 show the control system of the steam cabinet, including power supply circuit, single-chip microcomputer port control circuit, solenoid valve drive circuit, proportional valve drive circuit, ignition drive circuit, DC brushless Motor drive circuit, steam pump drive circuit, temperature / gear / gate control detection circuit, flame detection circuit, water level detection circuit, steam pump drive circuit and mode selection drive circuit, the proportional valve drive circuit drives the proportional valve connected to the DC The DC brushless motor drive circuit drives the connected DC brushless motor to cooperate to fully premix the gas and air to supply the burner with gas, the burner works, the water tank generates steam and outputs it to the steam cabinet, and through the steam pump, the steam is The heat release of food is accelerated, and the single-chip microcomputer port control circuit adjusts the fan speed according to t...

Embodiment 2

[0075] The difference between this embodiment and Embodiment 1 is the mode selection drive circuit. The mode selection drive circuit has four toggle switches, which can be combined into multiple modes. Each mode can choose a different gear switch type, manual or automatic mode, Different program settings are suitable for different devices.

Embodiment 3

[0077] The difference between this embodiment and Embodiment 1 is the gate control detection circuit. According to the signal sent by the gate control switch that several doors are in use, the large, medium and small fires are automatically selected. At the beginning, when the temperature is low, the fire is burned at the maximum , when the temperature reaches a certain level, the firepower is controlled by the number of doors used, and the specific parameters can be set by the program.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com