Universal electrical wire harness quick detection device and method

A detection device, the technology of General Electric, is applied in the direction of measuring device, electrical connection test, measuring electricity, etc., which can solve the problems of difficult operation, high labor cost, low efficiency, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

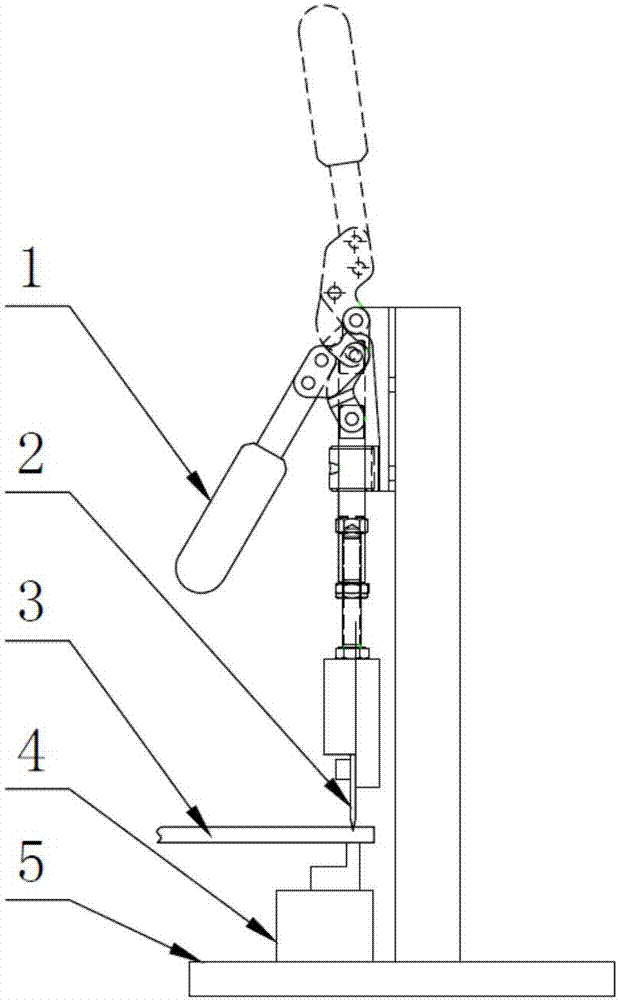

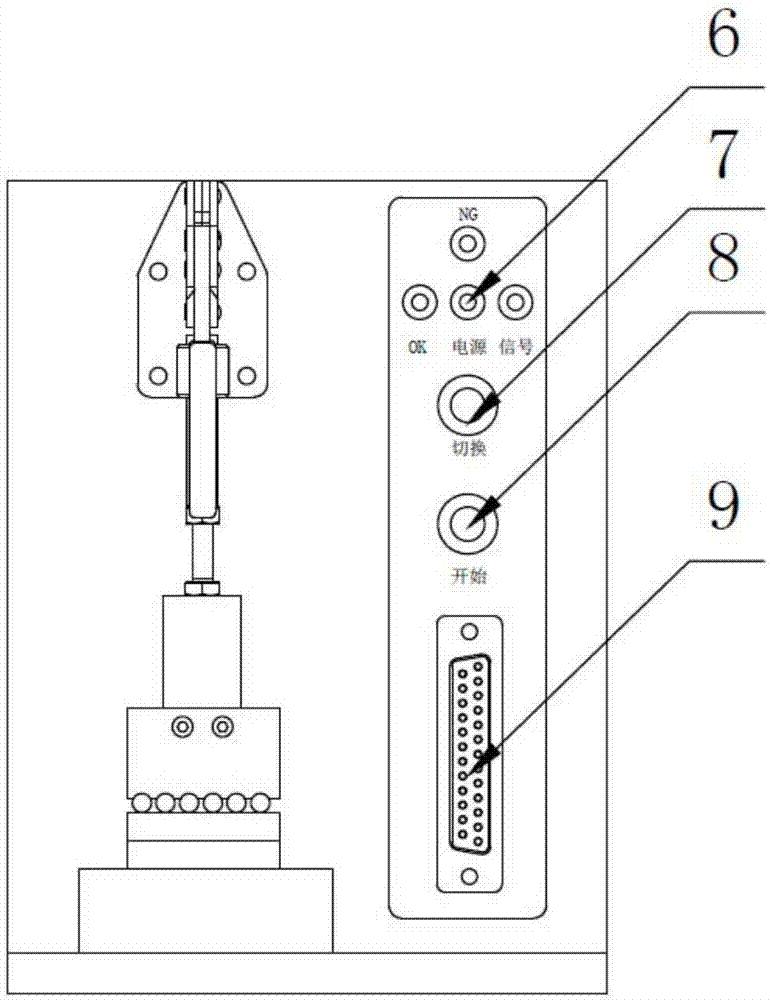

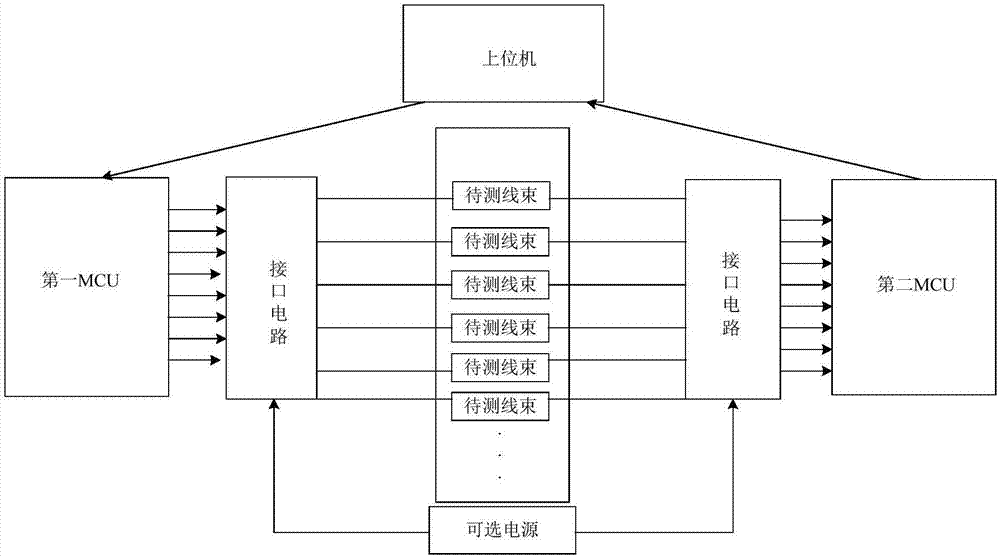

[0042] combine Figure 1 to Figure 2 As shown, the present embodiment provides a quick detection device for a general electric wire harness 3, which includes: a base 5, an insulating table 4, a cutter assembly, an insulating table 4, a wire harness interface 9 and a control system, and the insulating table 4 is arranged on The bottom of the base 5 is used to place the electric wiring harness 3 to be tested. The cutter assembly can be movably arranged above the insulating table 4 (when the cutter assembly is pressed down, the electrical wiring harness 3 to be tested is in a short-circuit state; when the cutter assembly is lifted, the electrical wiring harness 3 to be tested is in a short circuit state; In the disconnected state), the wire harness interface 9 is arranged on the side of the base 5 for accessing the electrical wire harness 3 to be tested; the control system includes: a host computer and signals connected to the host computer respectively The first MCU and the sec...

Embodiment 2

[0052] to combine Figure 1 to Figure 6 As shown, this embodiment also provides a method for a quick detection device for a general electric wire harness 3 according to Embodiment 1, which includes the following steps:

[0053] S1, laying the electrical wiring harness 3 to be tested on the insulating table 4;

[0054] S2. Connect one end of the electrical wire harness 3 to be tested into the wire harness interface 9;

[0055] S3. Control the cutter assembly to operate according to the detected category, wherein, when the cutter assembly is pressed down, the electrical wiring harness 3 to be tested is in a short circuit state; when the cutter assembly is lifted up, the electrical wiring harness 3 to be tested is in an open circuit state ;

[0056] S4. The control system performs detection processing according to the detection category, including:

[0057] S41. Send an instruction to the first MCU through the host computer. After receiving the instruction, the first MCU modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com