Equipment for recognizing composite material quality and interface by electric vortex flow

A composite material and eddy current technology, applied in the direction of material magnetic variable, etc., can solve the problem that the eddy current detector cannot realize the control of the detection depth, cannot meet the measurement requirements of thin-layer materials with different thicknesses, and does not have the function of identifying and locating the interface of composite materials, etc. problem, to achieve the effect of simple structure, strong anti-interference ability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

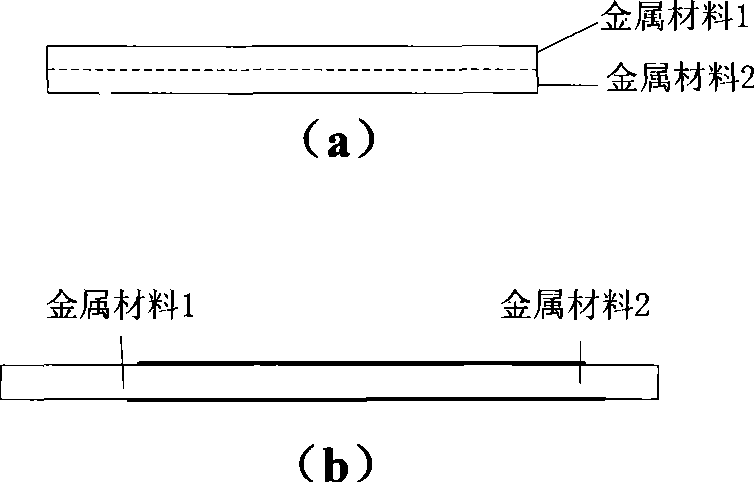

[0035] Such as figure 1 As shown, it is the detection object of this embodiment—the electrical component material. This type of composite material is made of two different non-ferromagnetic metal thin layer materials. Composite material, (b) is a composite material in which two materials are spliced back and forth.

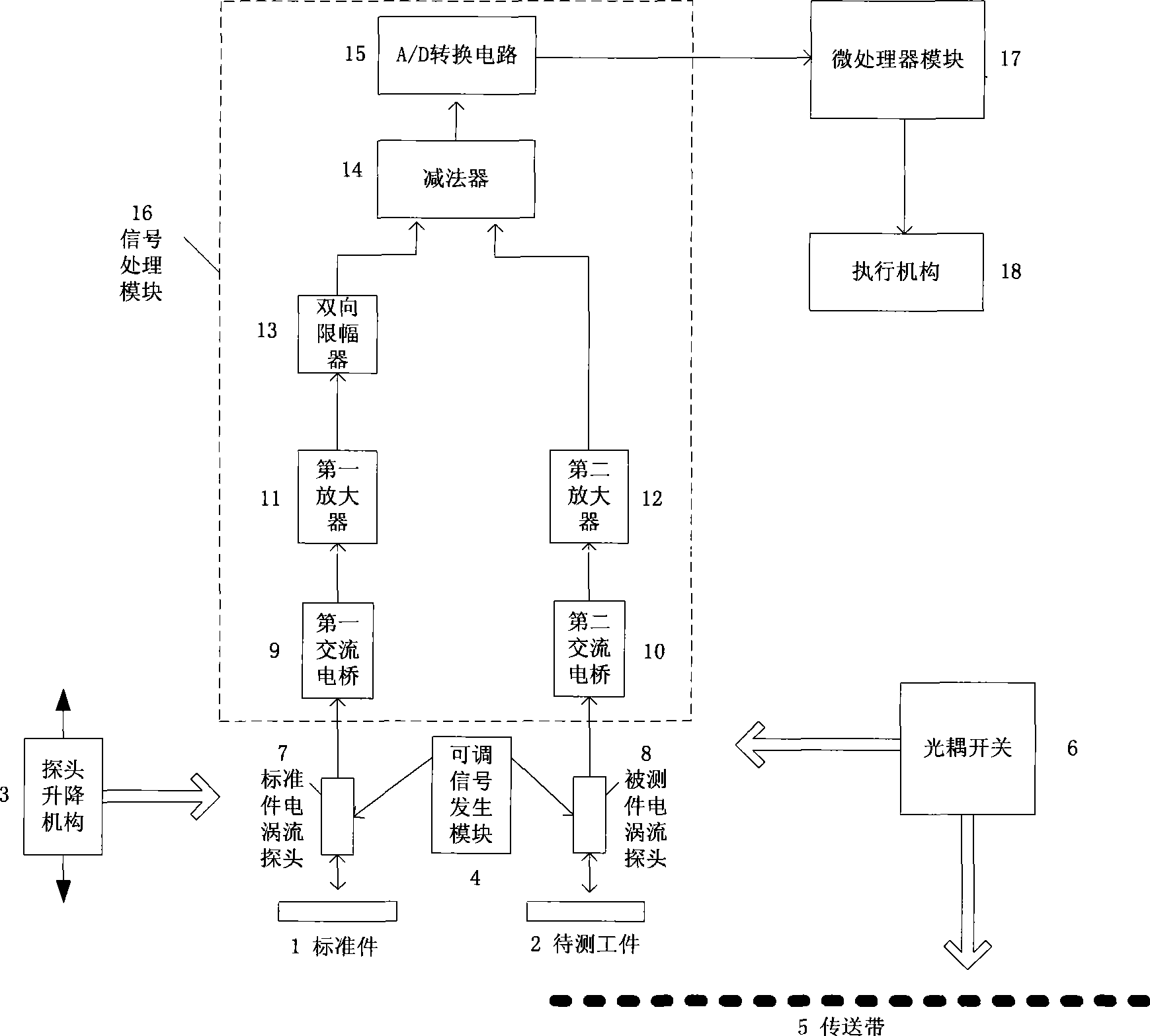

[0036] Such as figure 2 As shown, this embodiment includes: an adjustable signal generating module 4, an optocoupler switch 6, a standard eddy current probe 7, a DUT eddy current probe 8, a probe lifting mechanism 3, a signal processing module 16, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com