Diversion-type pipeline plugging device without stop of oil-gas conveying

A technology for conveying pipes and diversion pipes, which is applied in the direction of auxiliary devices, pipe components, pipes/pipe joints/fittings, etc., and can solve the problems of pipeline body impact damage, inconvenient construction work, and complicated sealant injection process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

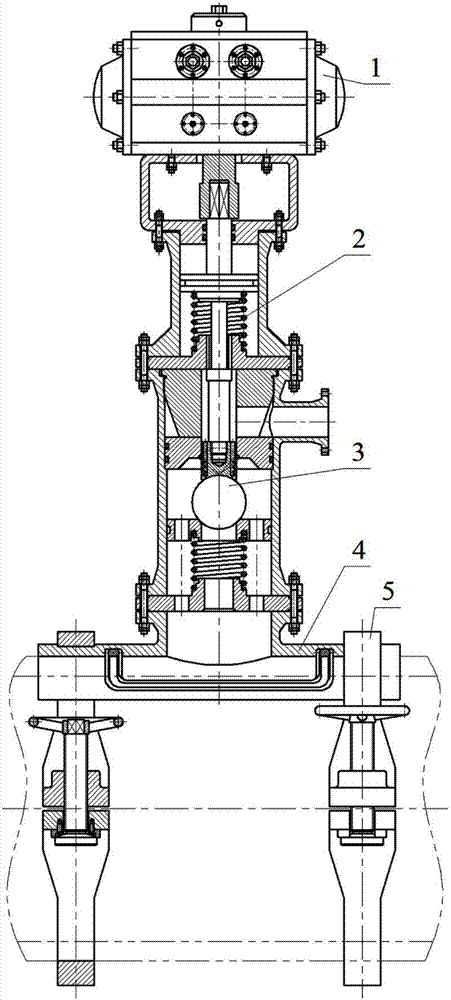

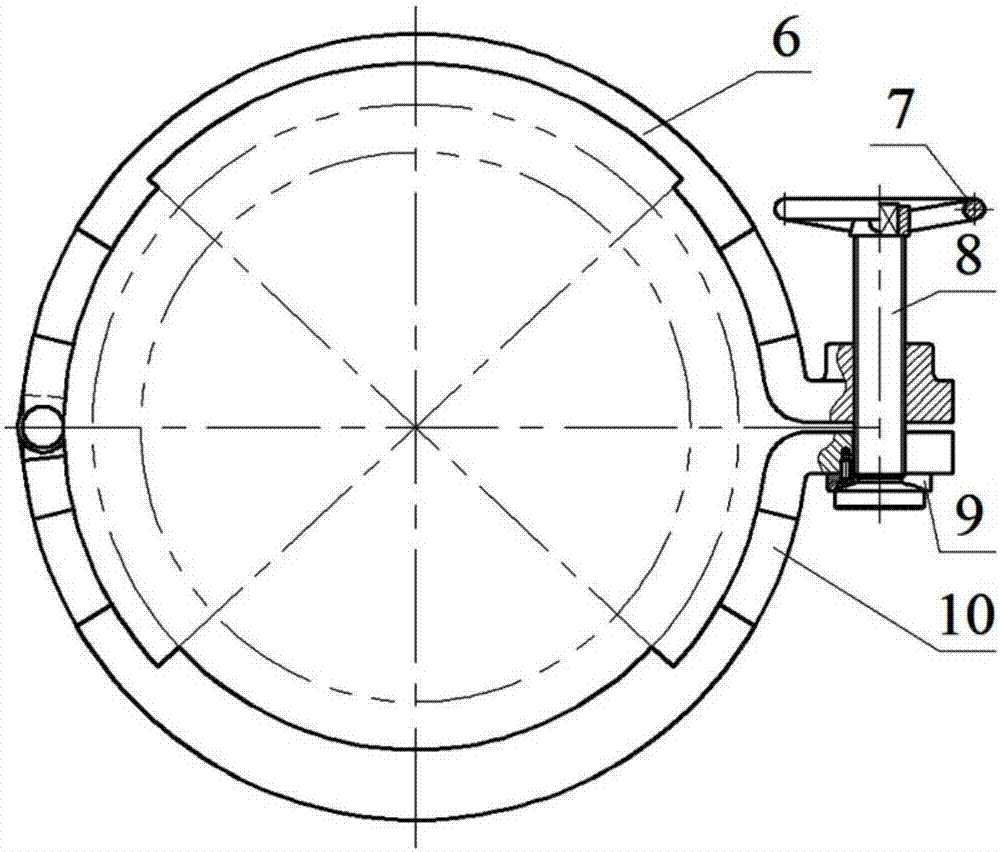

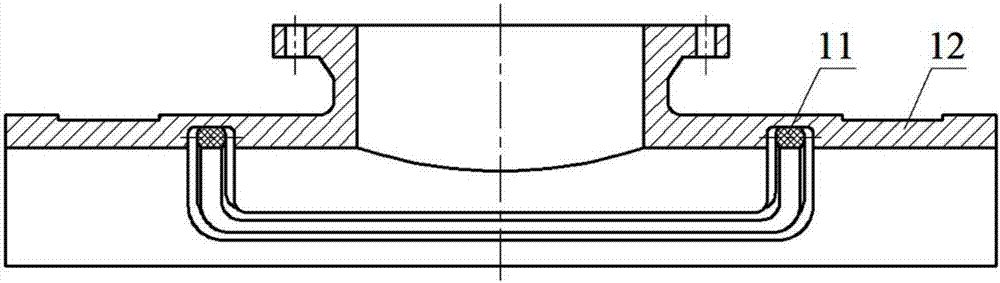

[0044] exist figure 1 Among them, the diversion type oil and gas non-stop pipeline plugging device is composed of a pneumatic valve group 1, an automatic controller 2, a deflector 3, a welding body 4 and a welding piece clamp 5. The pipeline leak plugging device adopts a left-right fully symmetrical structure, in which the welding piece fixture 5 consists of two symmetrically arranged monomers of the same model, while the pneumatic valve group 1, the automatic controller 2, the deflector 3 and the welding body 4 adopt a columnar monomer . The welding piece clamp 5 quickly clamps the welded body 4 to the leakage point of the oil and gas process pipeline according to the quick clamping mechanism and the screw mechanism, and according to the automatic control mechanism of the pneumatic valve group 1, the automatic controller 2 and the automatic diversion of the deflector 3 The mechanism implements the automatic diversion operation of leaking pressurized oil and gas and the weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com