Treatment method for strengthening soft soil foundation through combination of vacuum pre-pressing and foundation heating method

A soft soil foundation and treatment method technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of small strength increase and cannot meet the requirements of foundation use, and achieve the effect of reinforcement quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0029] A treatment method for strengthening soft ground by vacuum preloading combined with ground heating method, comprising the following steps:

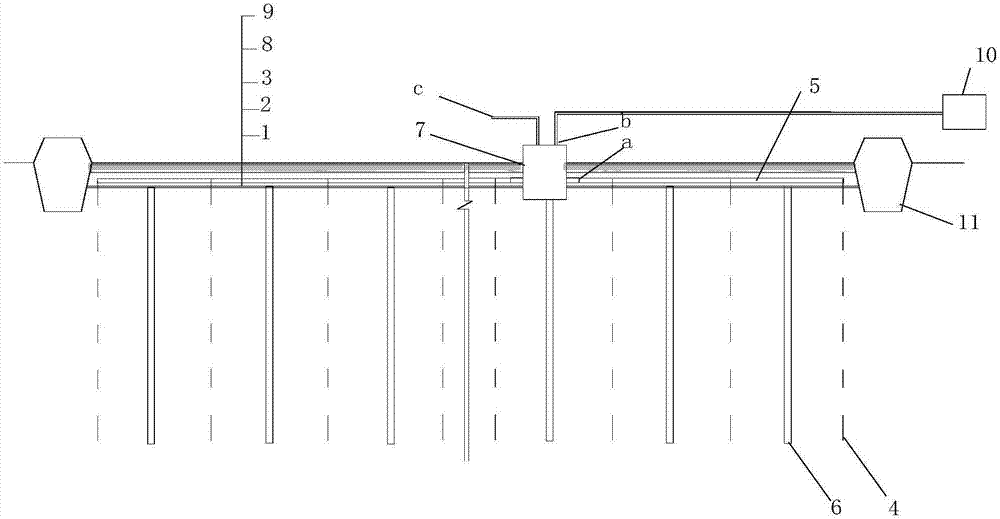

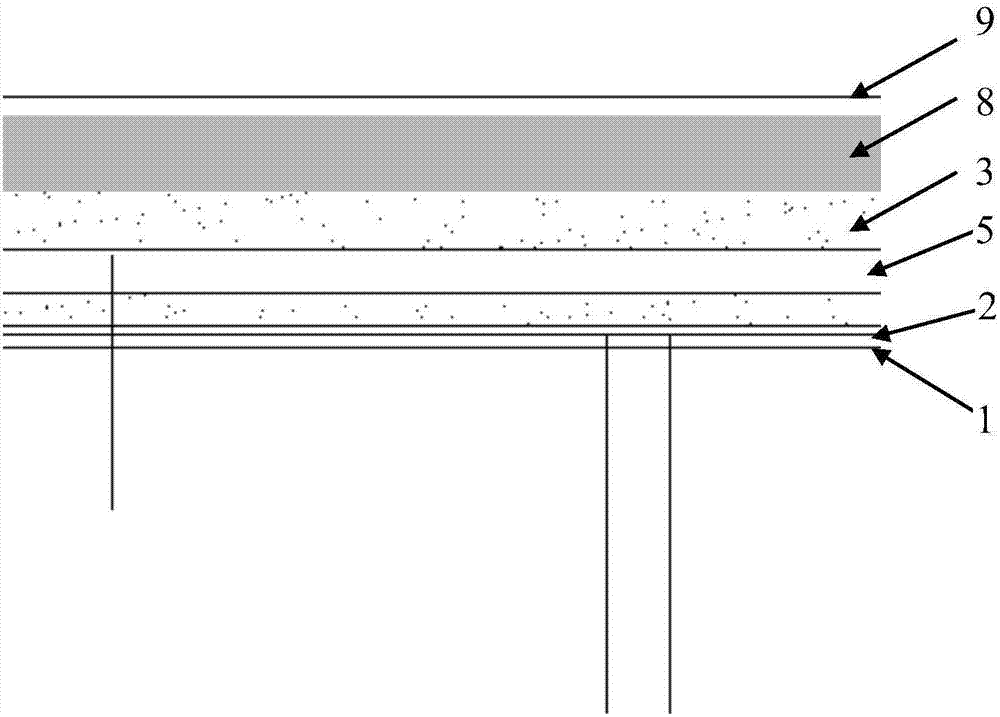

[0030] Step 1: Lay two layers of bramble 1 on the site to be treated, and lay 250g / m on the bramble layer 2 Weaving cloth 2, and laying 40cm thick medium-coarse sand 3 on the weaving cloth layer as a working cushion;

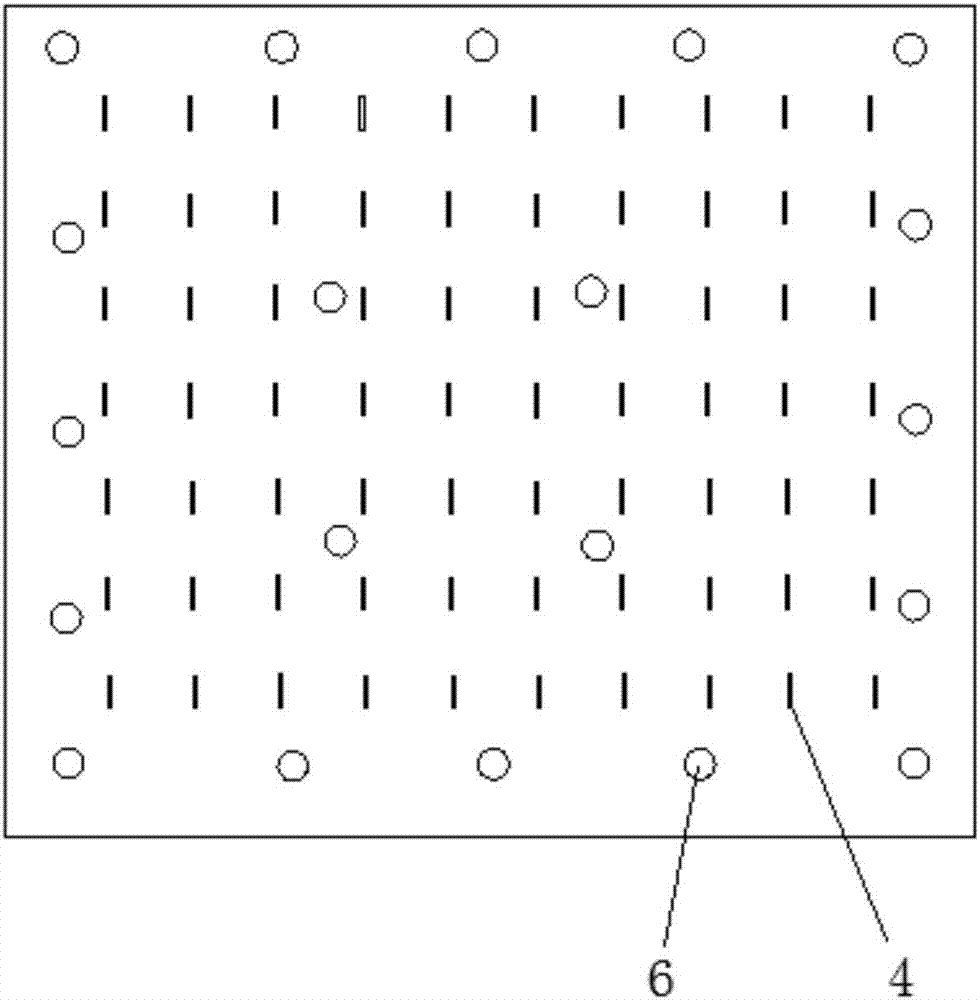

[0031] Step 2: Drill vertical plastic drainage boards 4 in the soil, the plastic drainage boards 4 are arranged in a lattice, lay horizontal filter pipes on the medium-coarse sand 3, and tie the heads of the plastic drainage boards 4 to the horizontally arranged filter pipes. on tube 5;

[0032] Step 3: Place the pressure guiding and diverting device 7 (the pressure guiding and diverting device 7 adopts "a pressure guiding and diverting device suitable for vacuum preloading foundation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com