InP/ GaP/ ZnS nucleocapsid quantum dots and preparation method thereof

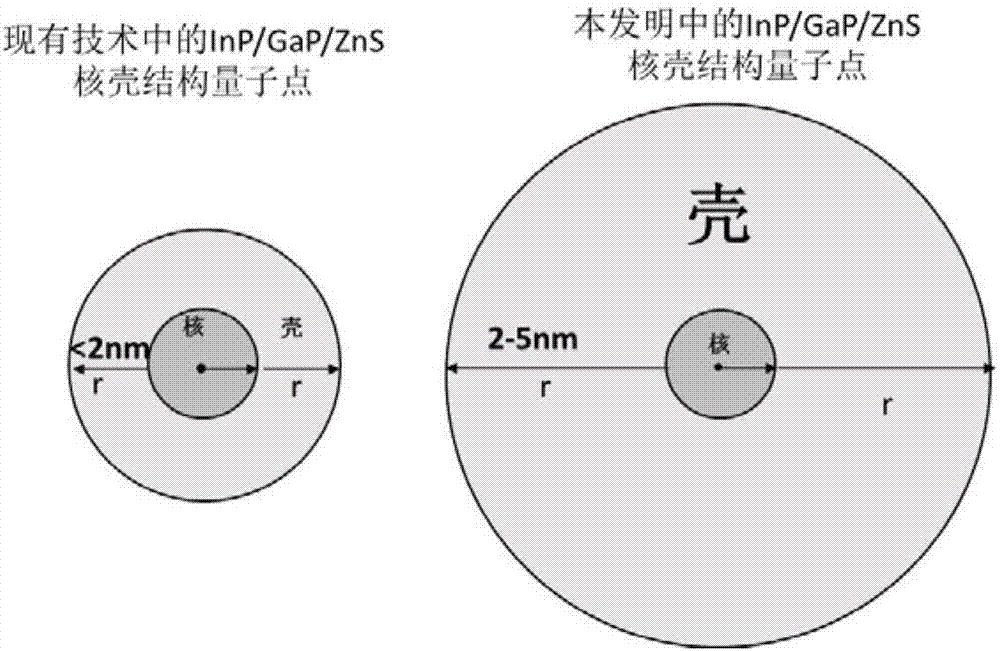

A core-shell quantum dot and quantum dot technology, which is applied in the field of InP/GaP/ZnS core-shell quantum dots and their preparation, can solve the problem of low quantum yield of quantum dots with related core-shell structures, difficulty in effective growth of ZnS shells, and crystallinity. The problem of poor lattice matching degree, etc., can improve the growth of ZnS shell, be easy to control, and reduce the lattice difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] One aspect of the present invention provides a method for preparing InP / GaP / ZnS core-shell quantum dots, which includes the following steps:

[0026] S1. Dissolving the indium precursor, gallium precursor and zinc precursor in an organic solvent to obtain an indium gallium zinc mixed precursor solution;

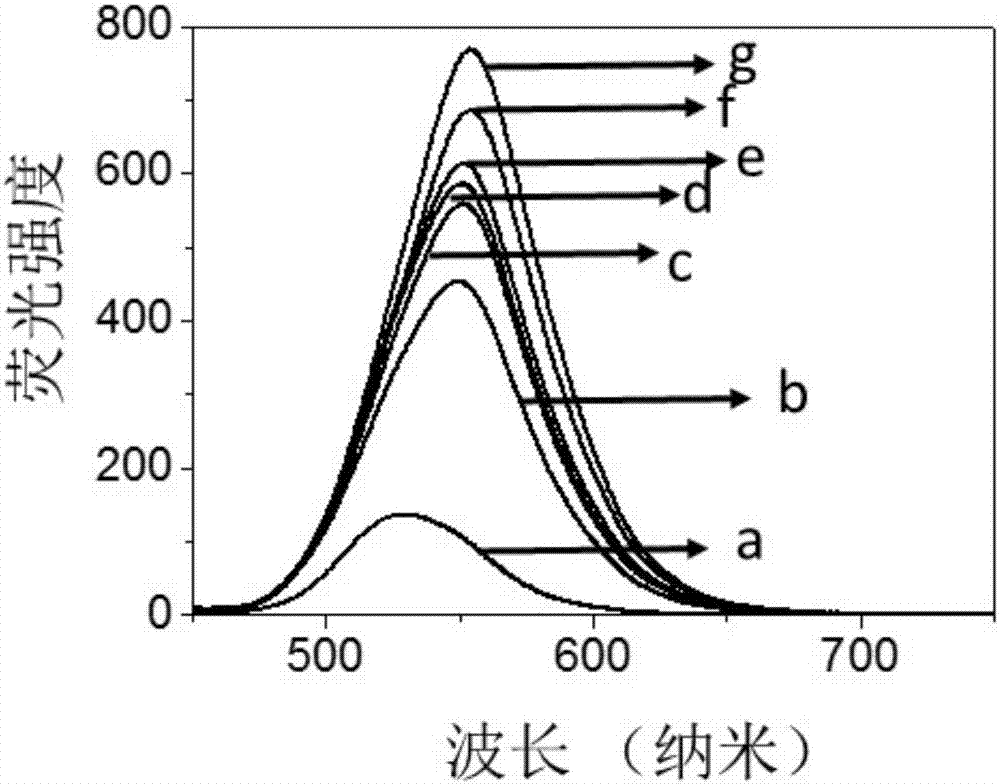

[0027] S2. Add a phosphorus precursor to the indium gallium zinc mixed precursor solution, and obtain an InP / GaP:Zn quantum dot core solution after the reaction;

[0028] S3. Add shell material to the InP / GaP:Zn quantum dot core solution multiple times at intervals for reaction, and the shell material is a mixed solution of zinc salt solution and mercaptan to obtain the InP / GaP / ZnS core Shell quantum dots.

[0029] According to a specific embodiment of the present invention, the indium precursor includes at least one of indium acetate, indium iodide, indium chloride, indium oleate, and indium stearate.

[0030] According to a specific embodiment of the present invention, the ga...

Embodiment 1

[0054] In this embodiment, the indium precursor is indium acetate, the gallium precursor is gallium chloride, the zinc precursor and the zinc salt are both zinc oleate, and the phosphorus precursor is tris(trimethylsilyl) ) Phosphorus, the thiol is an octaalkyl bidentate thiol. The organic solvent is a mixed liquid of liquid paraffin and oleic acid.

[0055] (1) Preparation of quantum dot core InP / GaP solution.

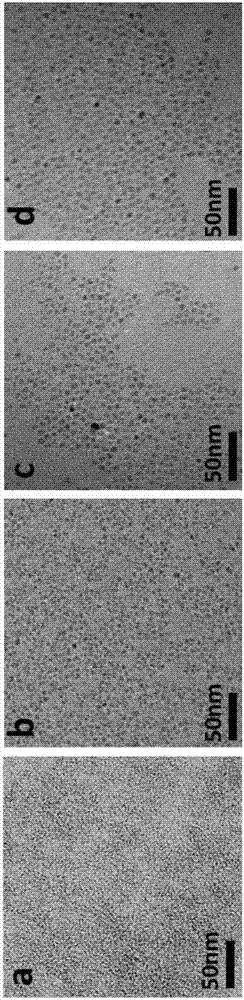

[0056] Take 0.3mmol of indium acetate, 0.1mmol of gallium chloride and 0.8mmol of zinc oleate and add them to a 100mL three-necked flask, and then add 10mL of liquid paraffin and 1mL of oleic acid. Exhaust air at 100°C for 40 minutes under the protection of nitrogen, then reduce to room temperature and add 0.5mmol tris(trimethylsilyl)phosphorus, then react at room temperature for 15 minutes and then quickly heat to 280°C for 20 minutes to obtain InP / GaP quantum dots Nuclear solution.

[0057] (2) Synthesis of the quantum dot shell ZnS coating the quantum dot core InP / GaP....

Embodiment 2

[0081] The preparation method of the InP / GaP / ZnS core-shell quantum dots of embodiment 2: refer to the preparation method of embodiment 1, except that the molar amount of Ga added when synthesizing the quantum dot core InP / GaP is 0.2 mmol, and other parameters are the same. The particle size of the InP / GaP / ZnS core-shell quantum dot is about 8.3 nm, the thickness of the shell layer is 3.1 nm, and the quantum yield is 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com