Method and apparatus for separating a suspension into a concentrate and a filtrate by means of cross-flow filtration

A technology of suspension and cross flow, which is applied in the field of separating suspension into concentrate and filtrate and equipment by means of cross flow filtration, which can solve the problems of increased filtration resistance, reduced filtrate flow rate, and temperature sensitivity of wearability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

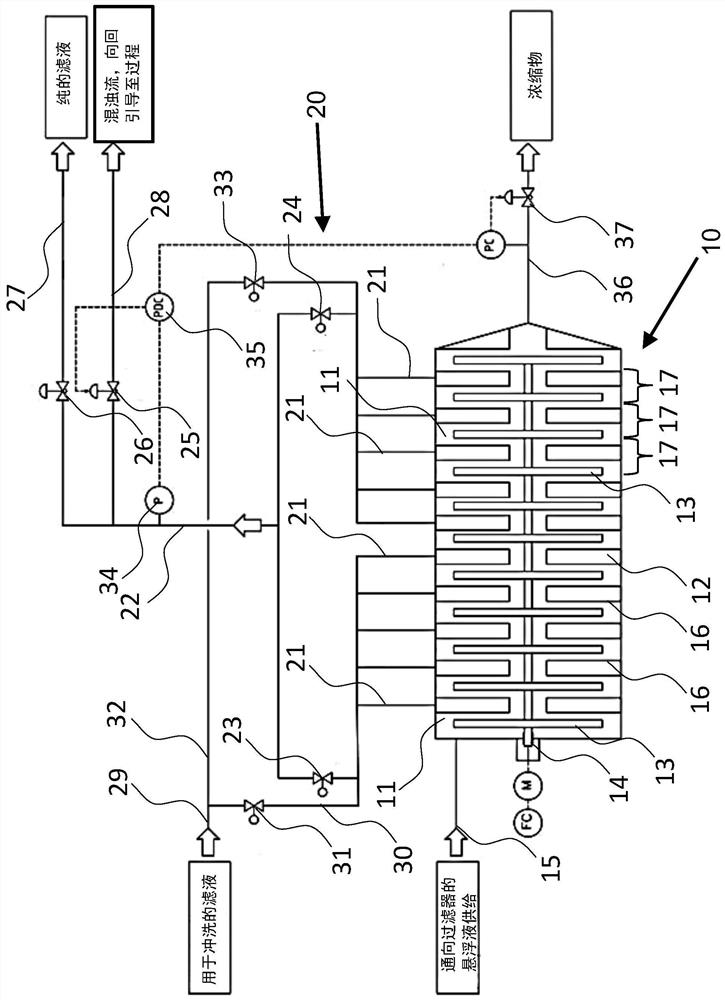

[0034] in figure 1 A filter device 10 according to the present invention has a corresponding line system 20 for the introduction of the filtrate. The filtering device 10 can be constructed in a modular manner, wherein each module in module 17 in sequentially set may have at least one suspension chamber 11 and the filter chamber 12. The suspension chamber 11 and the filter chamber 12 can be separated from each other by at least one filter element 16, such as a sieve. Along the common shaft 14, at least one stirring mechanism 13 can be provided in each module. The filter device 10 can be provided with any number of modules 17. In this case, module 17 can be configured to have a sub-axis, the sub-axis, can be combined into a shaft 14 of the filter device 10.

[0035] The suspension can be delivered to the suspension chamber of the filtration device 10 by the incubation line 15, the suspension chamber consisting of the suspension chamber 11 of each module 17. Introducing the flow line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com