Common mode current suppression circuit of motor drive system

A motor drive system and common-mode current technology, applied in electrical components, output power conversion devices, etc., can solve the problems of reduced common-mode current suppression effect and increased common-mode current, so as to achieve the reduction and increase of common-mode current Loop impedance, effect of achieving common mode current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

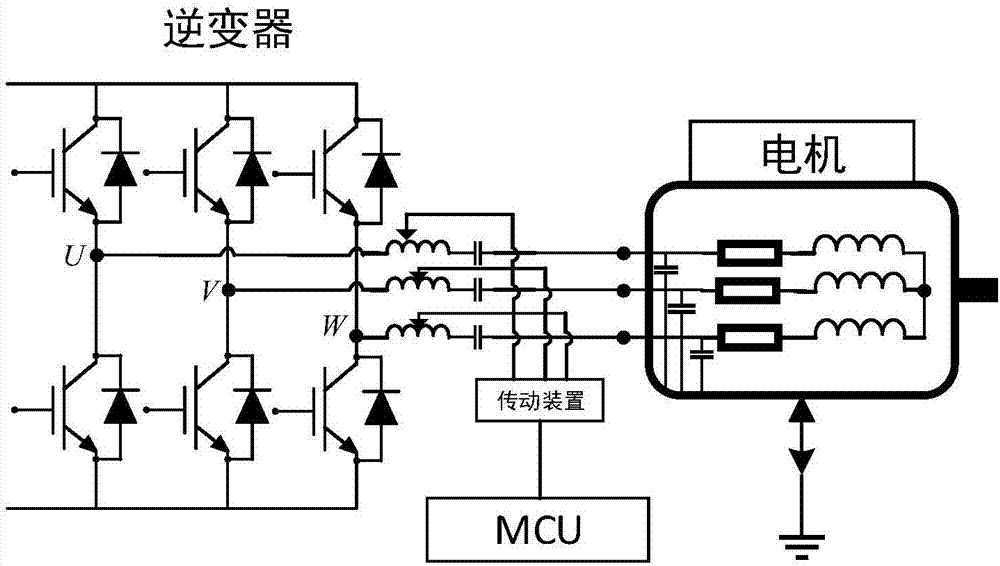

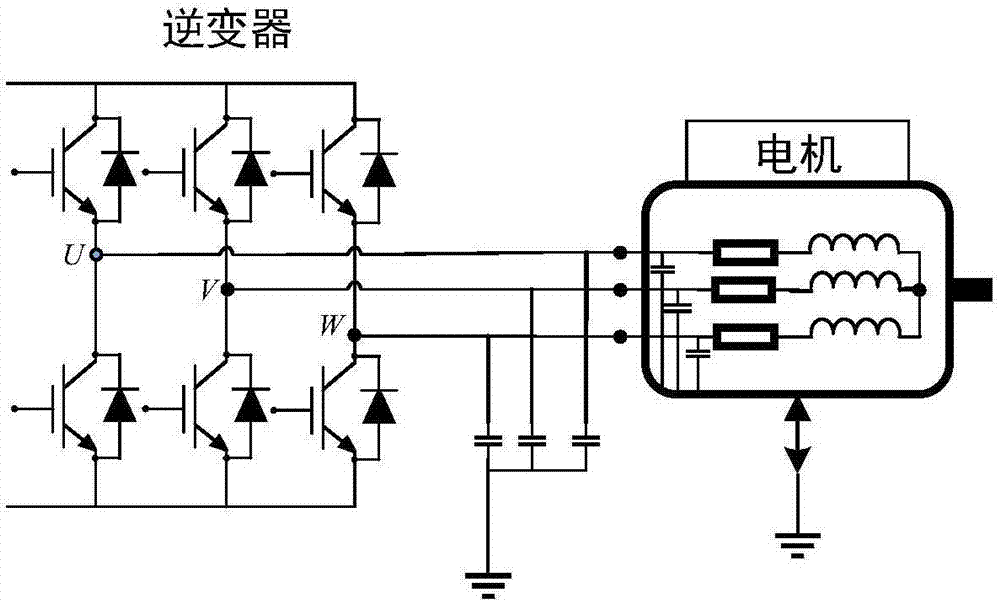

[0028] In this embodiment, a common-mode current suppression circuit for a motor drive system is provided, and its circuit structure is as follows figure 1 As shown, an LC filter circuit composed of an adjustable inductor L and a non-polar capacitor C is connected in series between the inverter output and the motor input. The value of the capacitor C is fixed at 100uF, and the inductance of the inductor L is controlled by the MCU. Transmission adjustment.

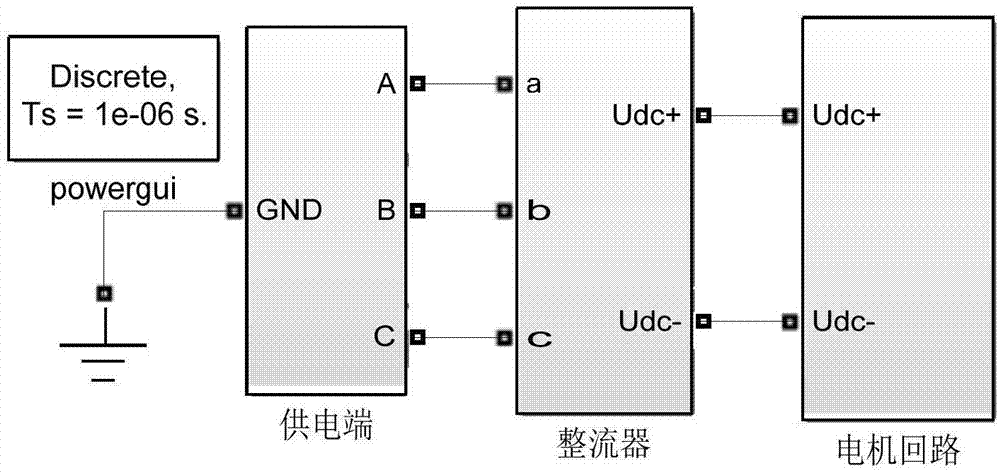

[0029] Simulation block diagram as image 3 As shown, the simulation block diagrams of the power supply circuit, rectifier circuit, inverter circuit and motor are shown in Figure 4 , Figure 5 , Figure 6 As shown; in the simulation, the carrier of the inverter control circuit is a 20kHz sawtooth wave, the modulation wave is a 50Hz sine signal, the inductance L of the common mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com