Bilateral staggered teeth 180° low thrust fluctuation continuous pole permanent magnet synchronous linear motor

A permanent magnet synchronous linear, low-thrust technology, applied in electromechanical devices, electrical components, propulsion systems, etc., can solve problems such as thrust fluctuations of dual-primary continuous-pole permanent magnet synchronous linear motors, and achieve the effect of improving performance and suppressing thrust fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

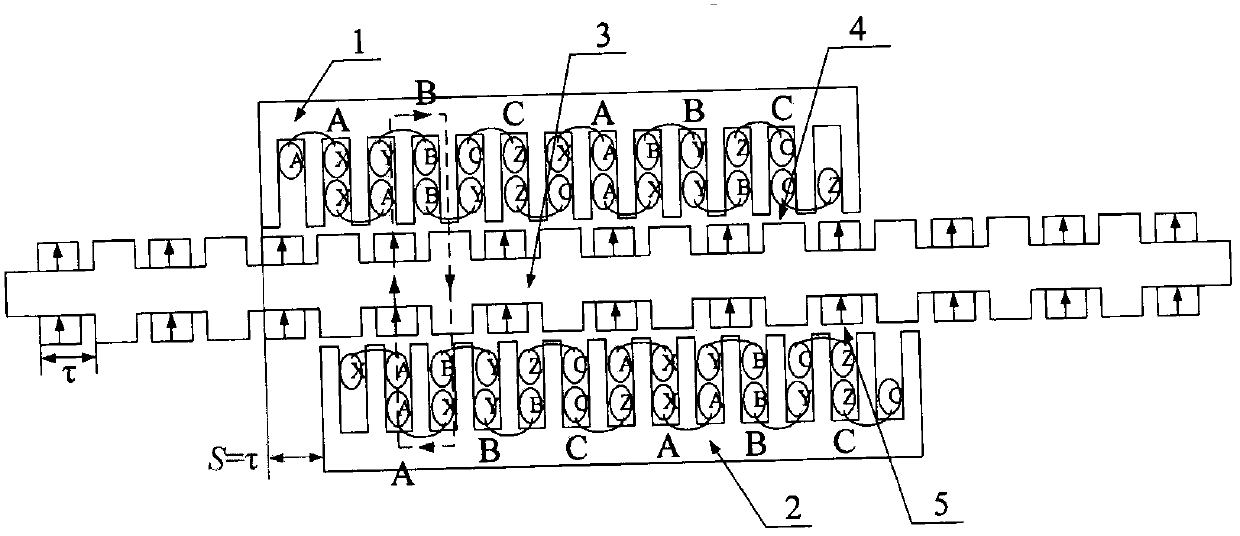

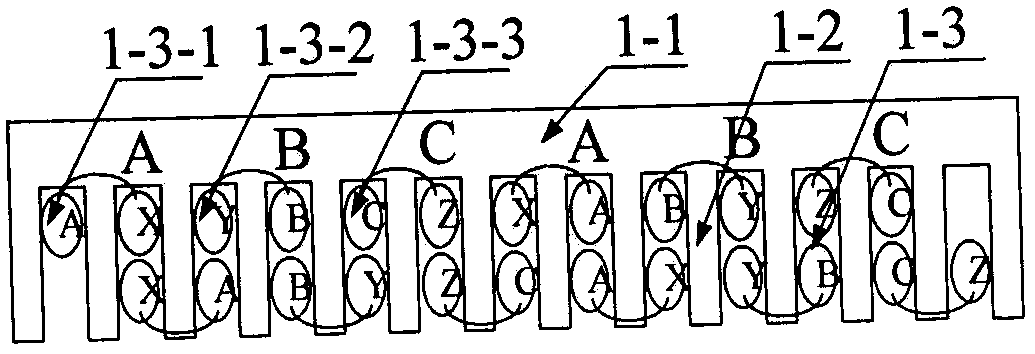

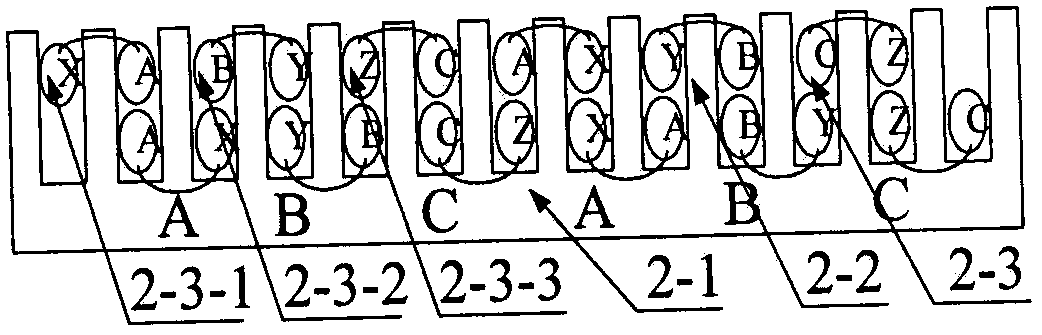

[0018] like figure 1 , 2 , 3, 4, and 5, the present embodiment is a double-sided staggered tooth 180° low-thrust fluctuation continuous pole permanent magnet synchronous linear motor, and its pole slot fits into a 10-pole 12-slot structure. Bilateral staggered teeth 180° low thrust fluctuation continuous pole permanent magnet synchronous linear motor, which includes a primary assembly 1, a primary assembly 2 and a secondary assembly 3. Primary component one 1 is composed of iron core yoke 1-1, iron core teeth 1-2 and armature winding 1-3. The primary component 2 is composed of core yoke 2-1, core teeth 2-2 and armature winding 2-3. The secondary assembly 3 is composed of a permanent magnet 3-1, an iron pole 3-2 and a yoke plate 3-3, each pair of poles includes two permanent magnets and two iron poles, and the permanent magnets on both sides of the yoke plate 3-3 The magnetization directions of 3-1-1 and 3-1-2 are the same, the iron pole 3-2-1 and iron pole 3-2-2 are integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com