Graphene oxide slurry, miniature graphene electrode and preparation method thereof and miniature graphene supercapacitor

A graphene electrode, graphene technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, inks, etc. The micro pattern is clear, the influence is small, and the capacitance performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of a graphene interdigitated electrode micro supercapacitor (MSC) of the present invention, comprising the following steps:

[0045] (1) Configuration of graphene oxide slurry:

[0046] Stir and dissolve polyvinylidene fluoride (PVDF) in N-methyl-2-pyrrolidone (NMP), among them, PVDF is used as a binder with a solid content of 0.5%, and the mixture of polyvinylidene fluoride and N-methylpyrrolidone The mass ratio is 1:199. Then add graphene oxide, the mass ratio of graphene oxide to PVDF is 20:1, and select a planetary gravity mixer to stir for 10 minutes to prepare graphene oxide slurry. In the present embodiment, graphene oxide is prepared by the Hummers method, and the specific preparation process is as follows:

[0047] (a) Add 3g of graphite and 18g of KMnO4 into a three-necked flask, stir evenly with a magnetic force, and cool to about 5°C to obtain a mixed solution A;

[0048] (b) Dissolve 360ml of H 2 SO 4 with 40ml of H 3 PO 4 Mix ev...

Embodiment 2

[0058] A method for preparing a graphene interdigitated electrode miniature supercapacitor (MSC) of the present invention is basically the same as in Example 1, the only difference being that the preparation process of step (3) graphene interdigitated electrode is as follows: (2) The obtained graphene oxide miniature interdigitated electrodes were suspended and fixed in a round-bottomed flask, and 5 ml of hydriodic acid (HI) with a mass fraction of 30% was added to the round-bottomed flask, refluxed at 90°C for 1 h, and then anhydrous Cleaned with ethanol to obtain graphene miniature interdigitated electrodes.

Embodiment 3

[0060] A preparation method of a graphene interdigitated electrode miniature supercapacitor (MSC) of the present invention is basically the same as Example 2, the only difference being that the preparation process of step (3) graphene interdigitated electrode is as follows: (2) The obtained graphene oxide micro-interdigitated electrodes were placed in an infrared drying oven, and the photothermal reduction was carried out by an infrared lamp for 1 h to obtain graphene micro-interdigitated electrodes.

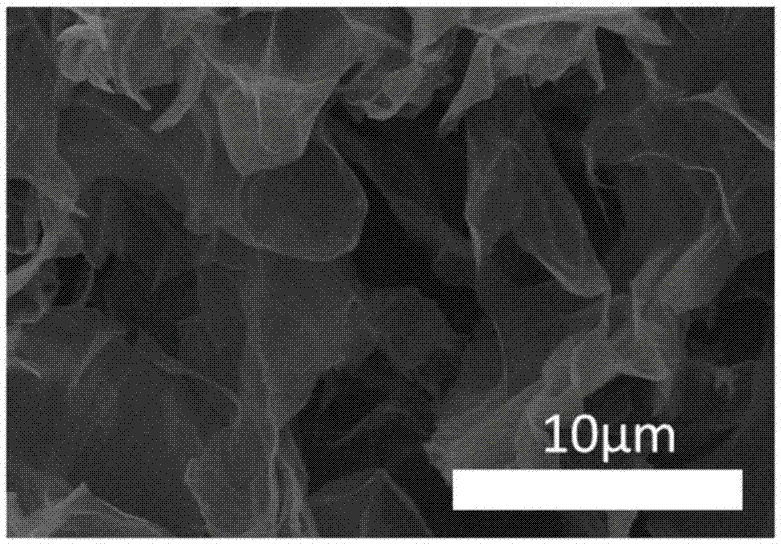

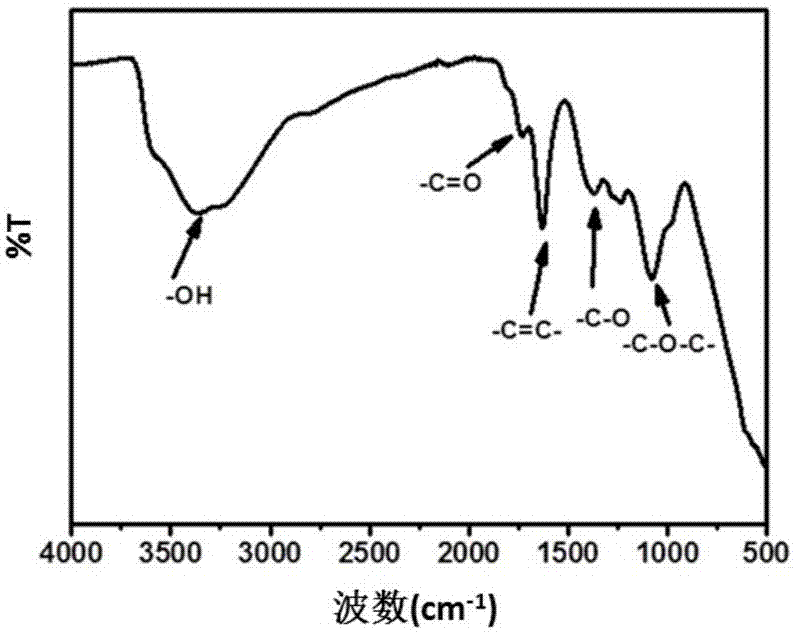

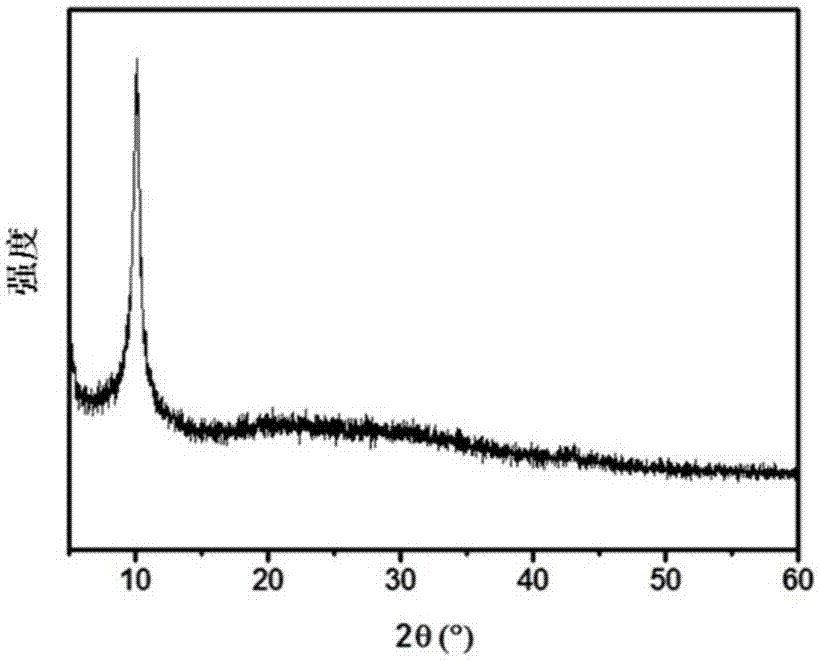

[0061] Figure 5 Figures A, B, and C are physical pictures of the graphene micro-interdigitated electrodes prepared in steps (3) of Examples 1 to 3, wherein, Figure A is Example 1, Figure B is Example 2, and Figure C is Example 3. Figure 5 The obvious comb-like structure can be seen in the A ~ C diagrams, and the area of the interdigitated electrodes is 16.9mm. 2 , which shows that the graphene oxide slurry prepared in step (1) is suitable for printing.

[0062] Figure 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com