Discrete element modeling and numerical simulation method for rock and earth mass triaxial test taking film effect

A triaxial test and rock-soil technology, applied in the field of three-dimensional discrete element modeling and simulation, can solve the problems of large overall surface friction, difficult effective simulation, complicated operation, etc., and achieve the effect of reducing boundary effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

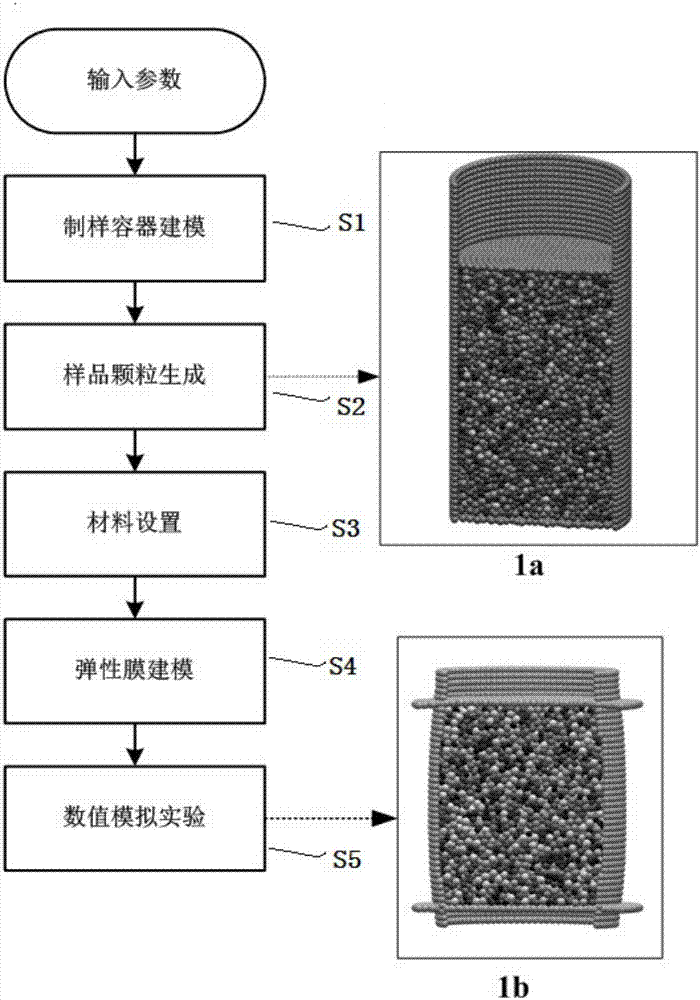

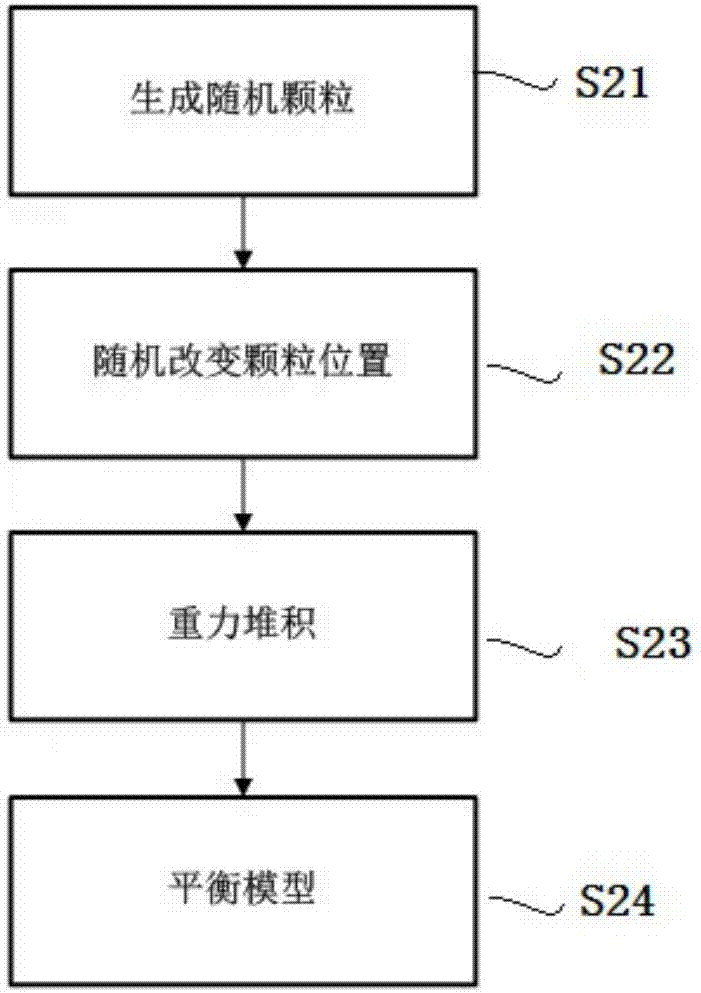

[0040] figure 1 The implementation flow chart of the numerical simulation method for rock and soil triaxial test considering the membrane effect, including discrete element modeling and numerical simulation experiment, is as follows:

[0041] First, set the physical and mechanical properties of the sample material and the geometric parameters of the model, including the size and material properties of the rock and soil sample (referred to as the sample), and the particle size of the particle sample that is the constituent unit of the rock and soil sample (ie, the sample unit) Distribution range, material properties of the elastic membrane, etc. Then start the construction of the discrete element model of the rock and soil triaxial test considering the membrane effect, that is, the modeling, including the following steps:

[0042] Step S1, modeling the sample preparation container.

[0043] The sample preparation container is composed of top, bottom plate and rigid cylinder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com