Method for measuring position of polyimide thin film and alignment marker

A polyimide film and alignment mark technology, which is applied in optics, instruments, nonlinear optics, etc., can solve the problems of non-compliance of liquid crystal display panels, inability to accurately adjust PI film, and influence of liquid crystal display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention provides a method for measuring the position of a polyimide film. The method for measuring the position of a polyimide film comprises the following steps:

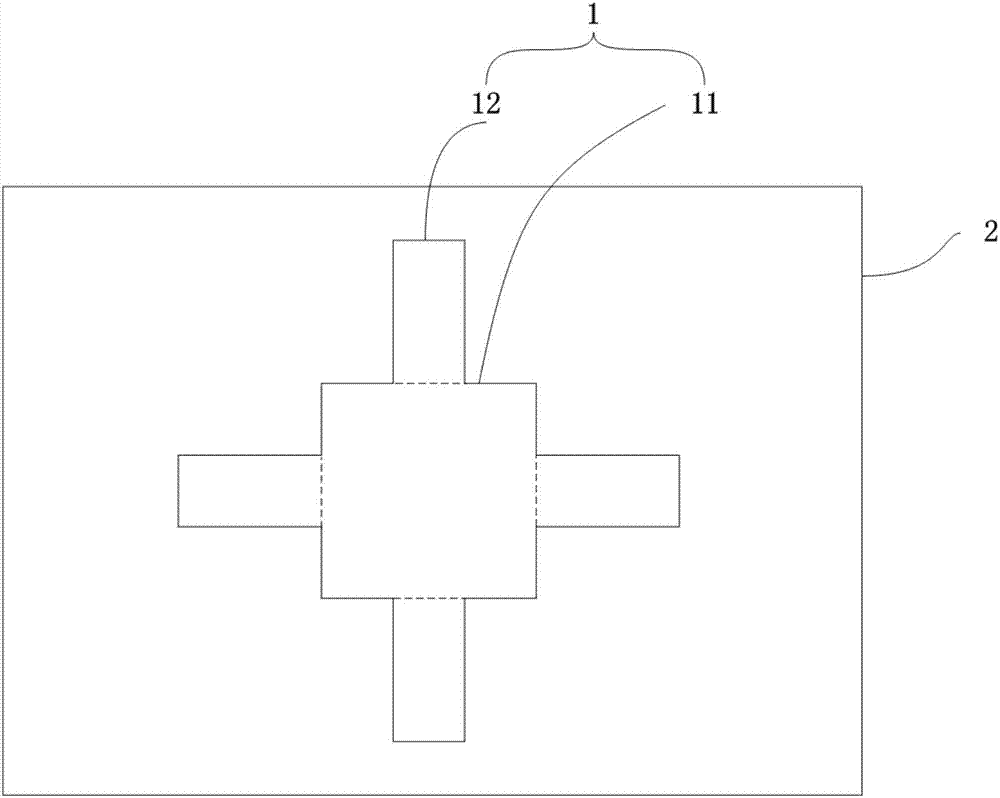

[0033] Such as figure 1 As shown, a substrate 2 is provided, and an alignment mark 1 is printed on the substrate 2. The alignment mark 1 is a symmetrical regular figure, and the center of the alignment mark 1 coincides with the center of the substrate 2; The longitudinal direction of the alignment mark 1 is consistent with the longitudinal direction of the substrate 2 , and the width direction of the alignment mark 1 is consistent with the width direction of the substrate 2 .

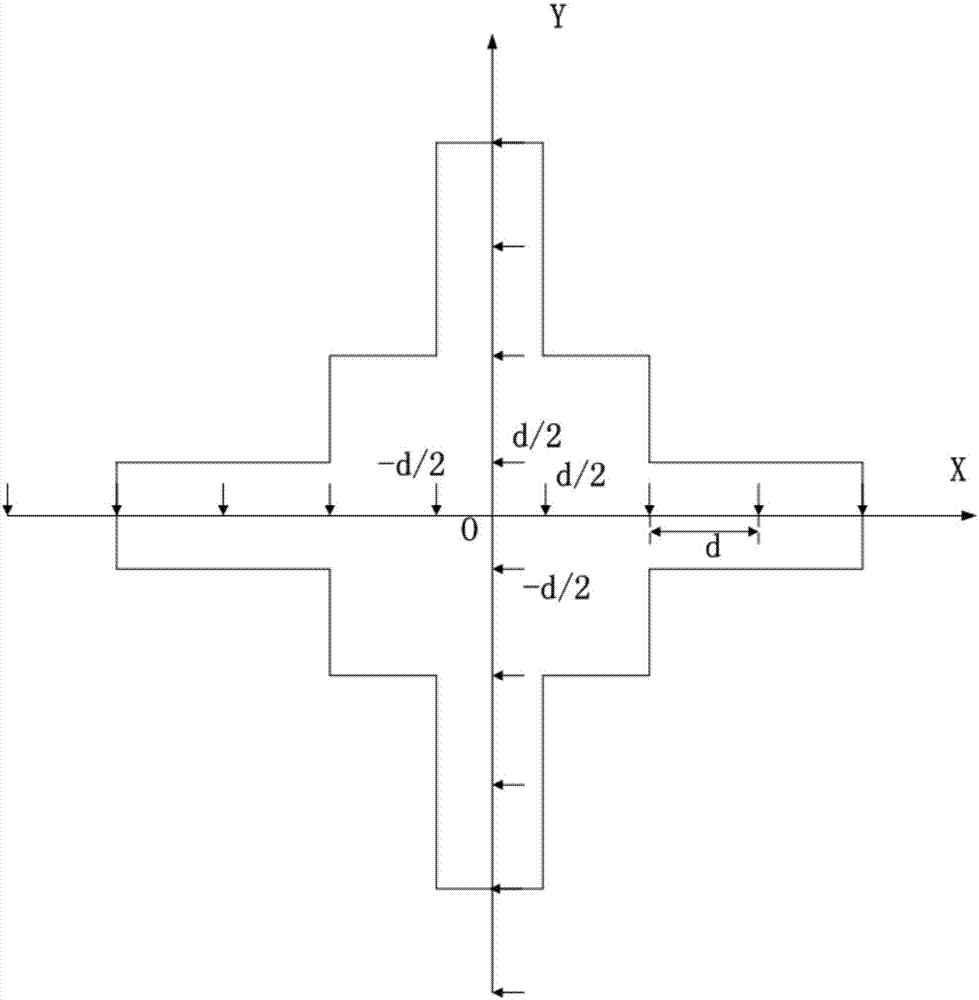

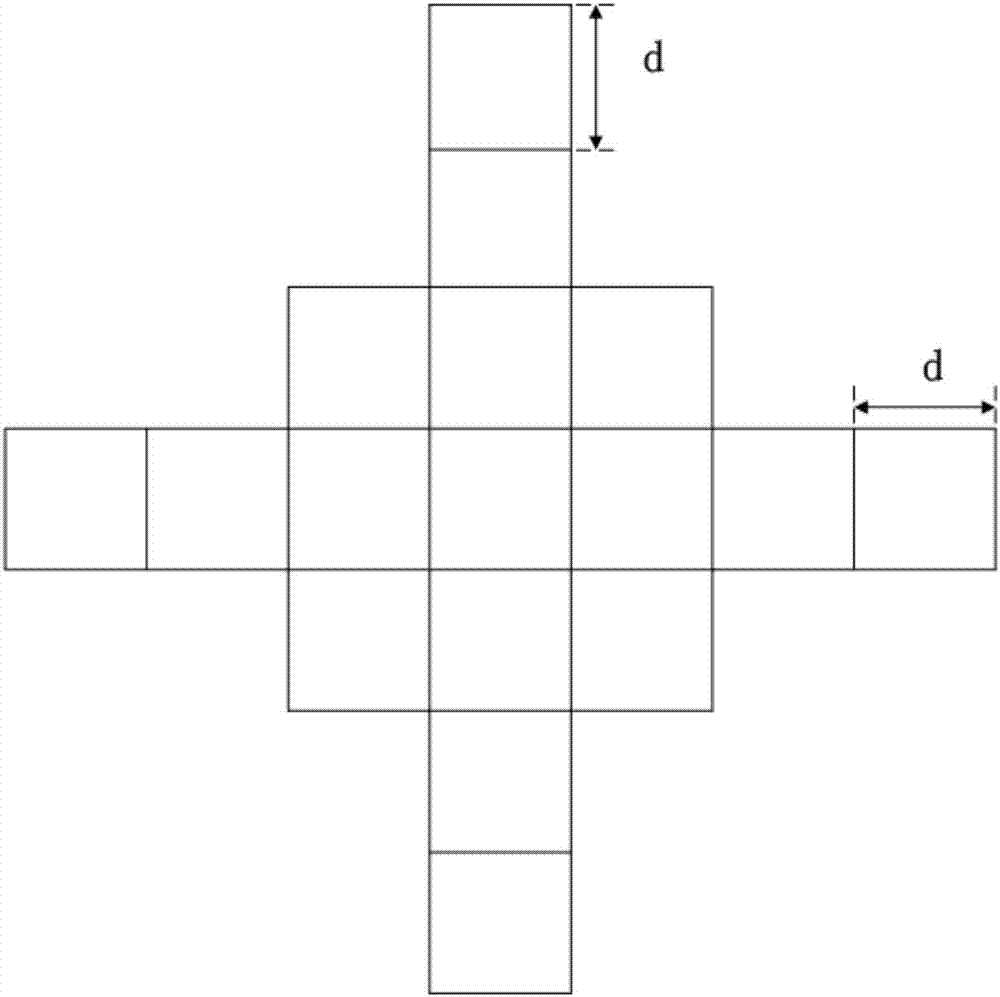

[0034] With the center of the alignment mark 1 as the origin, mark the scale on the alignment mark 1 according to the preset interval.

[0035] Prepare the polyimide film on the side with the alignment mark 1 printed on the substrate 2, measure the position of the polyimide film on the substrate 2 according to the scale of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com