Multi-factor combined aging experiment method for bushing main insulation

An experimental method and main insulation technology, applied in the testing of machine/structural components, measuring devices, instruments, etc., can solve the problems of low moisture efficiency, accelerated aging rate of capacitor cores, severe temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific implementation process, the present invention will be further described:

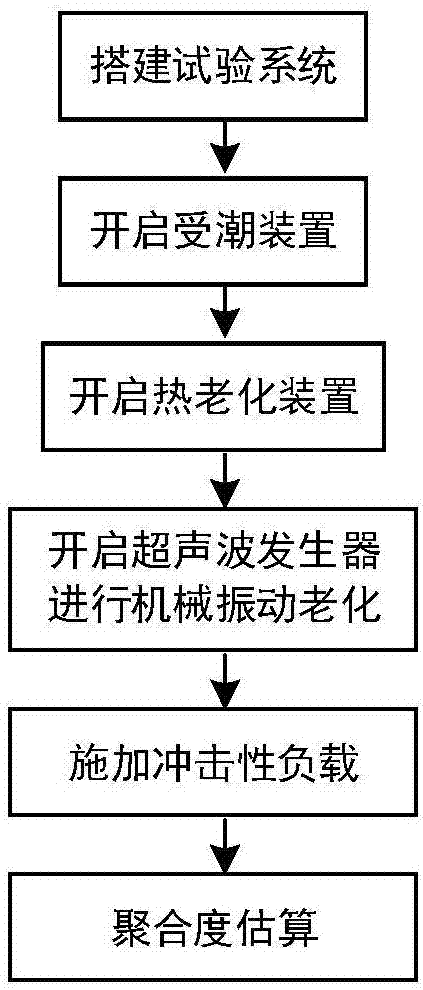

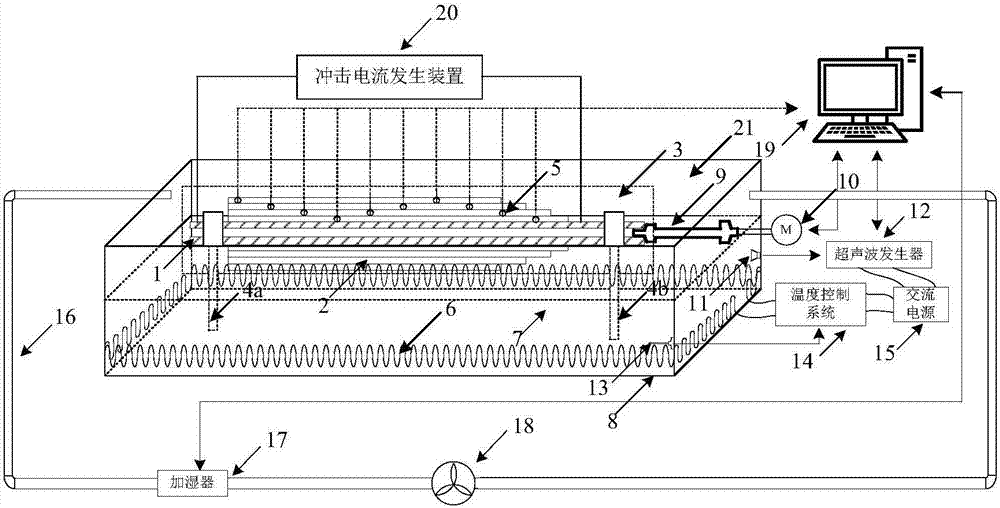

[0022] figure 1 It is the flow chart of the multi-factor joint aging method for the main insulation of the traction transformer bushing; figure 2 Shown is the multi-factor joint aging system for the main insulation of the traction transformer bushing; figure 1 It can be seen that the multi-factor joint aging method for the main insulation of the impact traction transformer bushing includes the following steps:

[0023] The first step: build the test system

[0024] Build a traction transformer bushing main insulation multi-factor joint aging system, mainly composed of capacitor core (3), insulating oil tank (8), impulse current generator (20), humidifier (17), ultrasonic transducer (11), Composed of a heating wire (6) and ancillary devices, the micro-water sensor (5) is evenly arranged in the gap between the capacitor core (3) and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com