Pipeline monitoring method and system based on LabVIEW

A monitoring system and pipeline technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of low monitoring efficiency and complicated pipeline monitoring methods, so as to improve efficiency, alleviate the complexity and simplify the pipeline monitoring methods. The effect of pipeline data monitoring method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

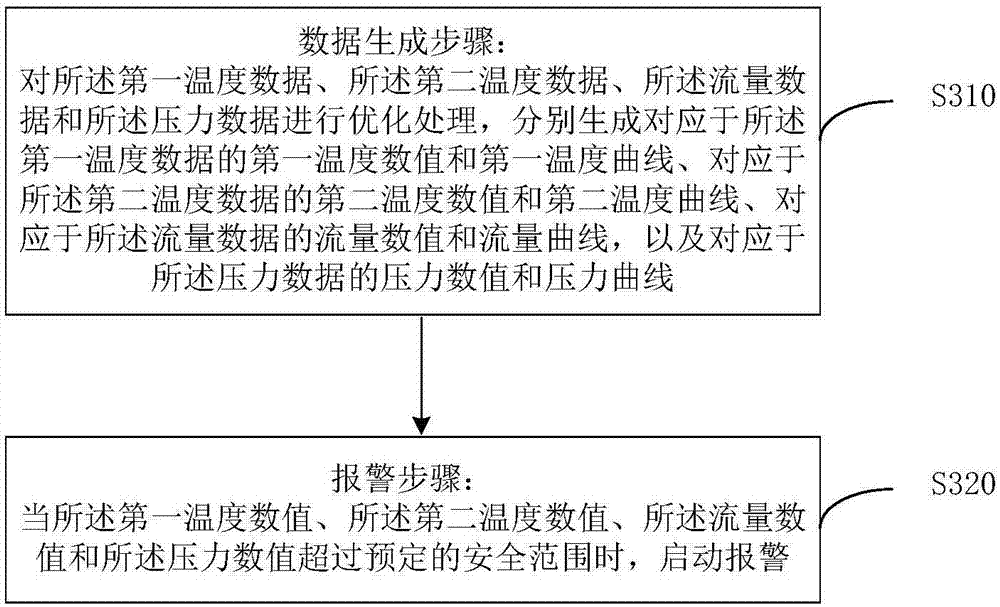

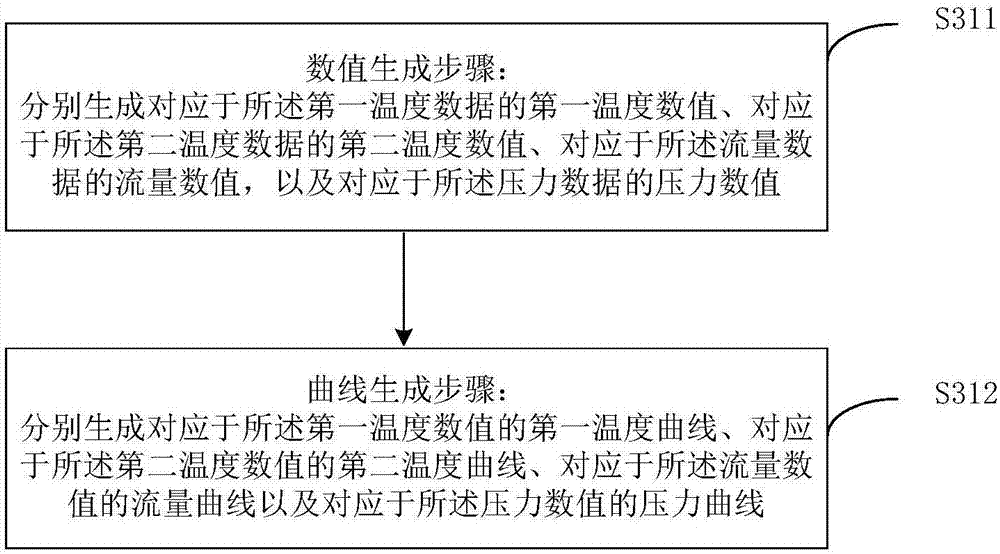

[0051] see figure 1 , a flowchart of a LabVIEW-based pipeline monitoring method provided by an embodiment of the present invention. A kind of pipeline monitoring method based on LabVIEW that the embodiment of the present invention provides, comprises:

[0052] Serial port initialization step S100: the serial port initialization unit performs data initialization settings on the resource name, baud rate, data bits, parity, stop bits and flow control corresponding to the VISA serial port. Among them, the resource name can be customized according to user needs. The setting of baud rate and data bit refers to the output serial port parameters of the data acquisition device of the lower computer. The default parity is none, and the stop bit can be customized according to user needs. Set, the default flow control is none, the serial port initialization is the basis for the normal data communication using the VISA serial port, through the initialization of the VISA serial port, the r...

Embodiment 2

[0067] see Figure 4 , a schematic structural diagram of a LabVIEW-based pipeline monitoring system provided by an embodiment of the present invention. A pipeline monitoring system based on LabVIEW provided by an embodiment of the present invention includes: a serial port initialization unit 100 , a data reading unit 200 , a data processing unit 300 and a data display unit 400 .

[0068] The serial port initialization unit is connected with the data reading unit, and the serial port initialization unit performs data initialization settings on the resource name, baud rate, data bits, parity, stop bits and flow control corresponding to the VISA serial port. Among them, the resource name can be customized according to user needs. The setting of baud rate and data bit refers to the output serial port parameters of the data acquisition device of the lower computer. The default parity is none, and the stop bit can be customized according to user needs. Set, the default flow control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com