Bionic sealing ring for reciprocating dynamic sealing

A sealing ring and dynamic sealing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as failure, and achieve the effect of small deformation, simple structure, and not easy to fatigue failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

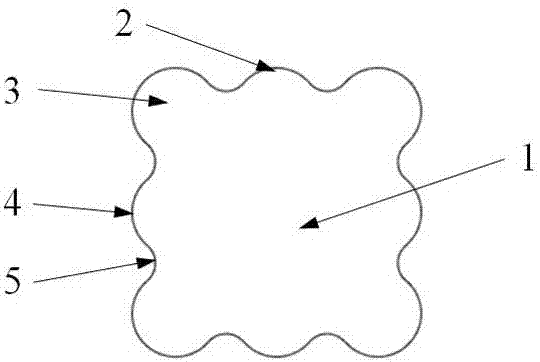

[0012] Such as figure 1 As shown, a bionic sealing ring for reciprocating dynamic sealing is composed of a sealing ring body 1; the sealing ring body 1 has four contact surfaces 2, and the two ends of the contact surfaces 2 are circular contacts 3, and the contact surfaces 2 are distributed in the middle There are one or two or three circular protrusions 4, the circular protrusion 4 and the circular contact 3 are smoothly connected through the groove 5, and the multiple circular protrusions 4 can also be smoothly connected through the groove 5; The groove 5 is a V-shaped or U-shaped structure, and the bottom of the groove 5 is a circular arc transition.

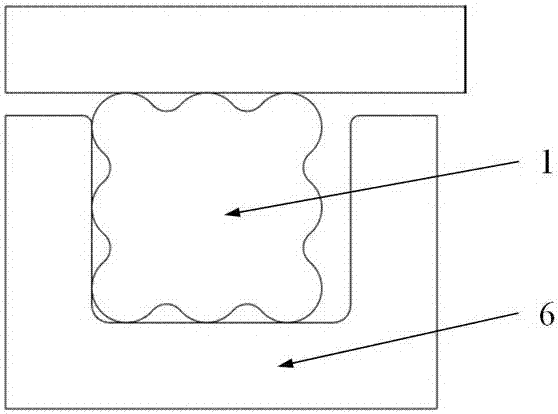

[0013] Such as figure 2 As shown, installing the sealing ring body 1 in the sealing groove 6 can realize static sealing and reciprocating dynamic sealing; the material of the sealing ring b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com