Hot-rolled U-shaped steel sheet pile

A steel sheet pile, U-shaped technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of increased weight and volume, inconvenient construction, uneconomical, etc., to achieve light and fast construction, save labor in pulling out piles, and improve bending resistance The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. What needs to be declared here is that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features and technical means involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

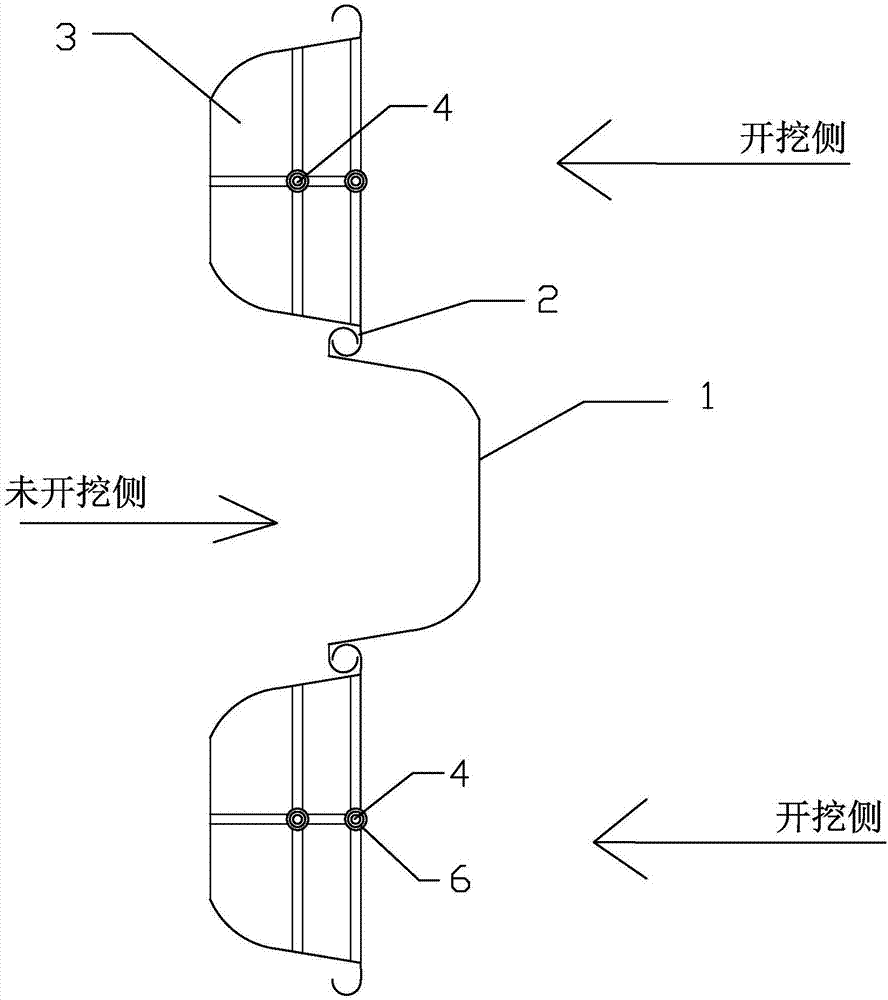

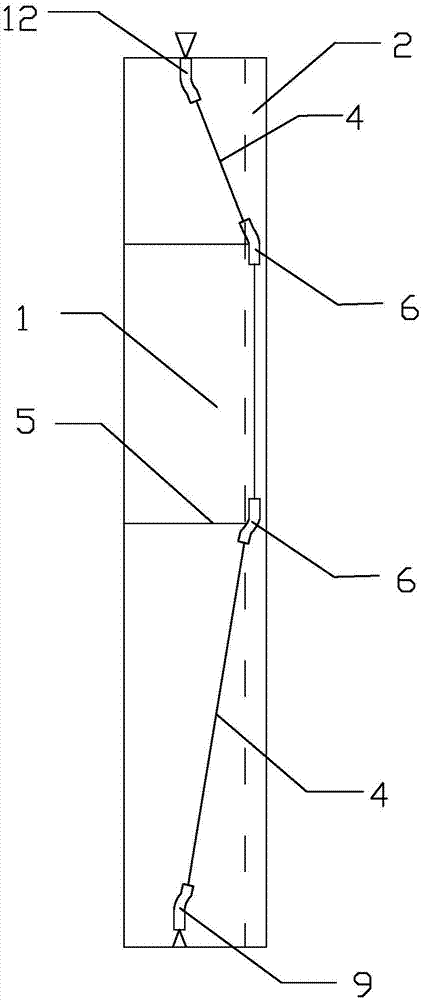

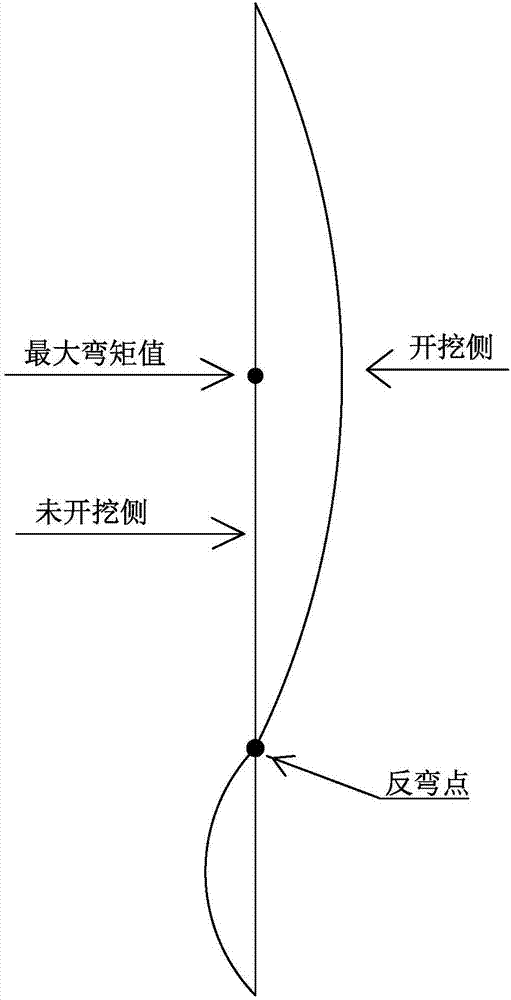

[0028] Such as figure 1 As shown, the hot-rolled U-shaped steel sheet piles of the present invention include several pile bodies 1 of hot-rolled U-shaped steel sheet piles with curling 2 on both sides. Fasten with curl 2. The present invention still adopts traditional smaller-sized hot-rolled U-shaped steel sheet piles such as PU400X170 hot-rolled U-shaped steel sheet piles. A number of two adjacent hot-rolled U-shaped steel sheet piles h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com