Template pull tube device for adhering woven tape to rear neckline

A collar and webbing technology, which is applied in textiles and papermaking, cloth feeding mechanisms, sewing equipment, etc., can solve the problems of easy stretching and deformation of webbing, easy sewing crooked, asymmetrical webbing, etc. Slotting and precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

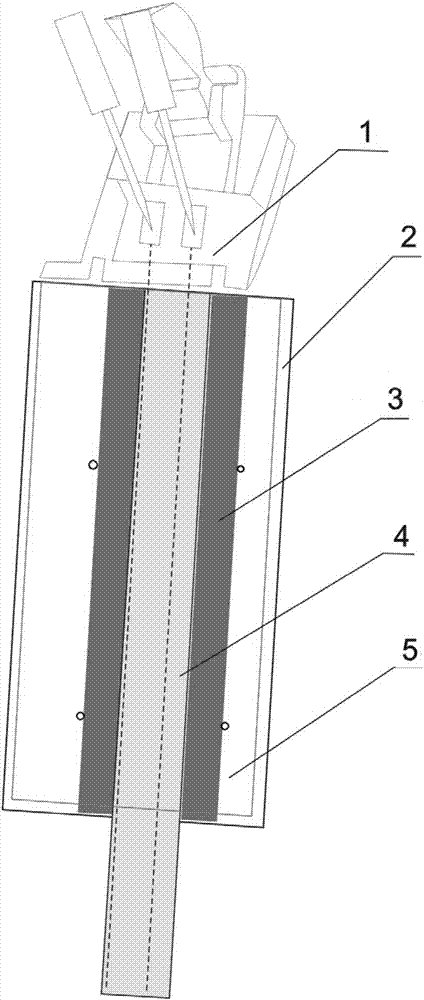

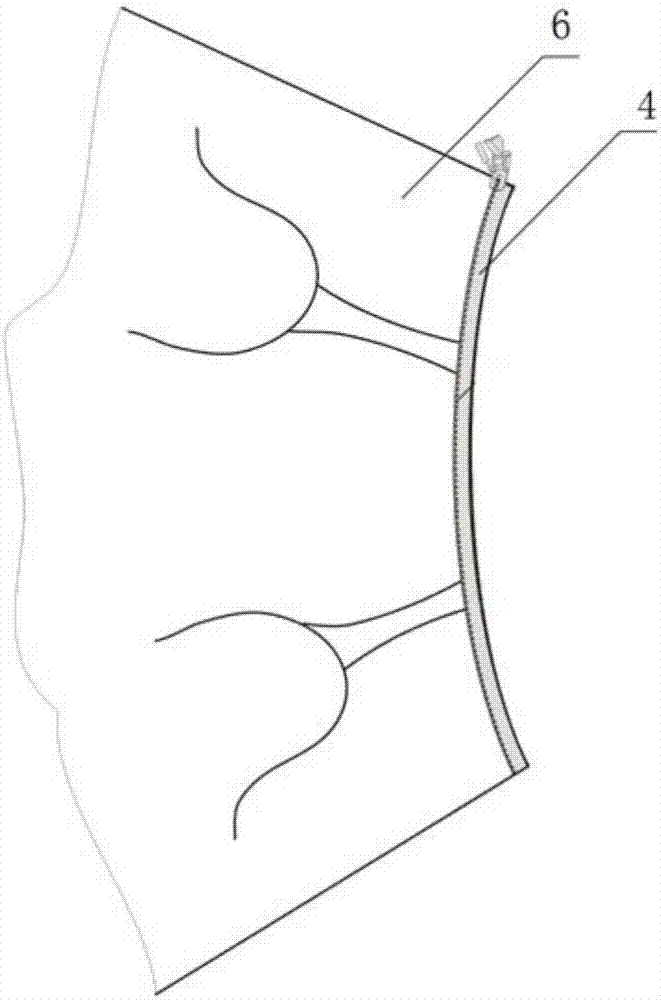

[0023] A template puller device for pasting webbing on the back collar, such as figure 1 , including the bottom plate 2, the surface plate 5 and the intermediate spacer 3 between the bottom plate 2 and the surface plate 5, the middle spacer 3 is provided with a positioning groove for placing the webbing 4, the positioning groove is the same width as the webbing, and the middle The interlayer 3 is made of foam material, sandwiched between the bottom plate 2 and the surface plate 5 by pressing, the bottom plate 2 and the surface plate 5 are connected and fixed by yellow glue, the bottom plate 2 and the surface plate 5 are The glass plate is preferably an acrylic plate. The positioning groove is a long strip groove with a depth of 3-5mm and a length of 20-30cm. The positioning groove is a long strip arc groove, which is suitable for the shape of the back collar. There are scales on the bottom plate, and positioning pins for positioning the intermediate layer are also provided on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com