Vehicle rear-floor frame structure, vehicle body and vehicle

A frame structure and rear floor technology, applied in the field of vehicles, can solve the problems of the overall modal influence of the rear floor, the failure of the rear floor depression, and the easy occurrence of bending, so as to ensure the structural strength and reliability, improve the overall modal, improve the The effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

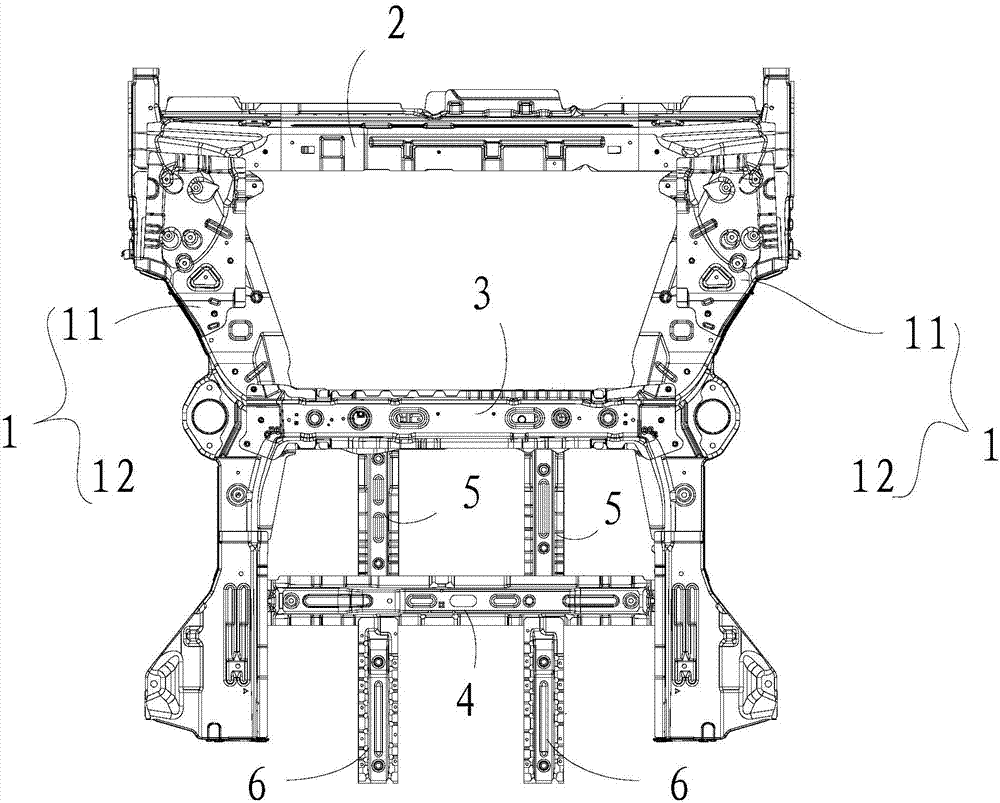

[0029] This embodiment relates to a vehicle rear floor frame structure, which is suitable for a vehicle with a short rear overhang, so as to improve the overall mode of the vehicle rear floor and ensure the reliability of the structure at the rear floor. Such as figure 1 As shown in , the rear floor frame structure of the vehicle includes a pair of longitudinal beams 1 extending along the length direction of the vehicle, and a beam assembly extending along the width direction of the vehicle is connected between the longitudinal beams 1 on both sides. The beam assembly specifically includes between the longitudinal beams 1 connected on both sides, and is close to the rear of the vehicle, that is, with figure 1 The direction shown in is the reference, the first beam 2 connected between the tops of the longitudinal beams 1 on both sides.

[0030] In this embodiment, the crossbeam assembly further includes a second crossbeam 3 connected between the longitudinal beams 1 on both si...

Embodiment 2

[0039] This embodiment relates to a vehicle body on which the vehicle rear floor frame structure as described in Embodiment 1 is installed. Meanwhile, the present embodiment also relates to a vehicle having the vehicle body as described above. The vehicle body and vehicle of this embodiment can ensure the structural strength of the rear floor of the vehicle by adopting the vehicle rear floor frame structure as described in Embodiment 1, and can ensure the reliability of force transmission at the rear floor of the vehicle when the vehicle collides, thereby improving The overall mode at the rear floor of the vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com