Structure pulverizer facilitating dust prevention

A technology of a pulverizer and a discharging mechanism, which is applied in cyclone devices, grain processing, etc., can solve the problems of high input cost, multiple manpower, material resources, discomfort, etc., and achieves low input cost, protection of human health, and high packaging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

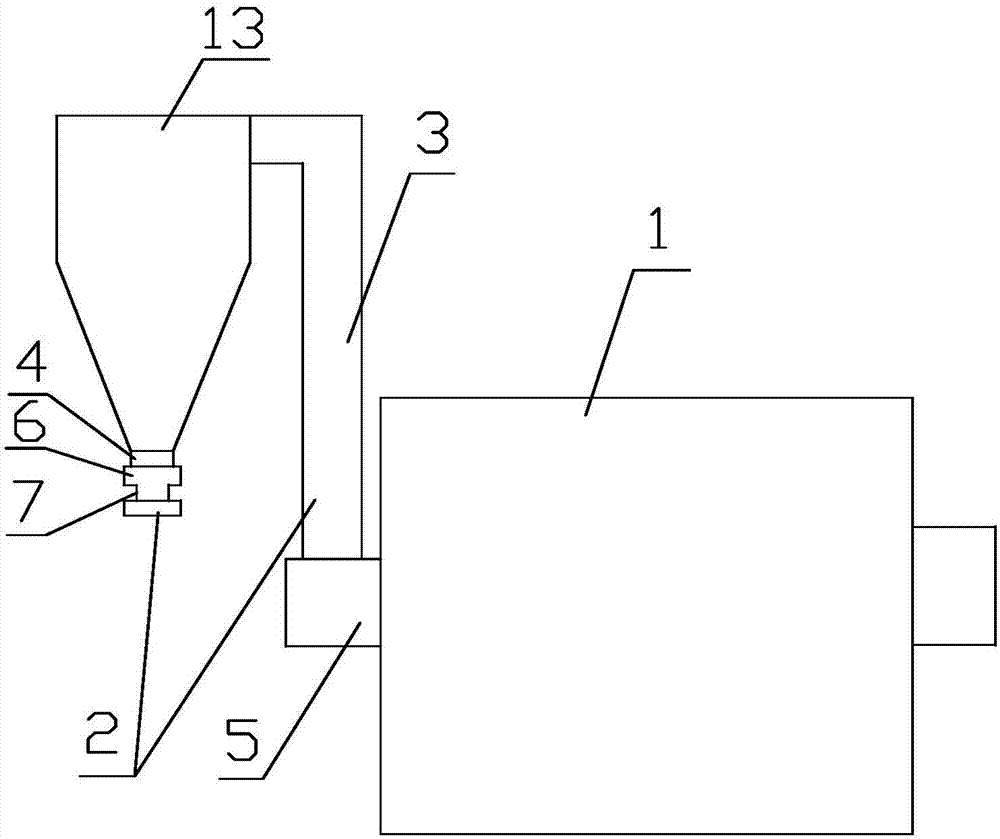

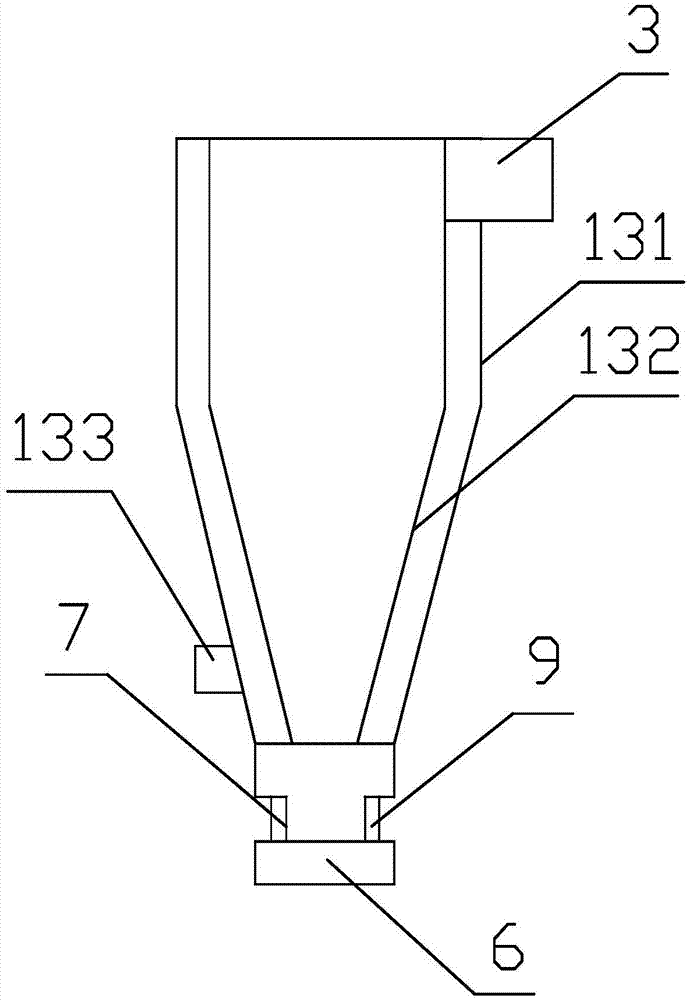

[0028] like figure 1 As shown, the invention discloses a pulverizer with an advantageous dust-proof structure, which includes a pulverizer main body 1 and a discharge mechanism 2 , and the discharge mechanism 2 includes a discharge pipeline 3 and an output pipe 4 . The input end of the discharge pipe 3 is connected to the discharge port 5 of the pulverizer main body 1, and the output end is provided with an output pipe 4. The side wall of the output pipe 4 is convexly provided with a fixed ring 6 along the circumferential direction, and the fixed ring 6 is concave along the circumferential direction. A fixing groove 7 is provided. A fastening ring 8 is also included, and the fastening ring 8 is used for installing the mouth part of the packaging bag on the fixing groove 7 so that the output pipe 4 communicates with the packaging bag.

Embodiment 2

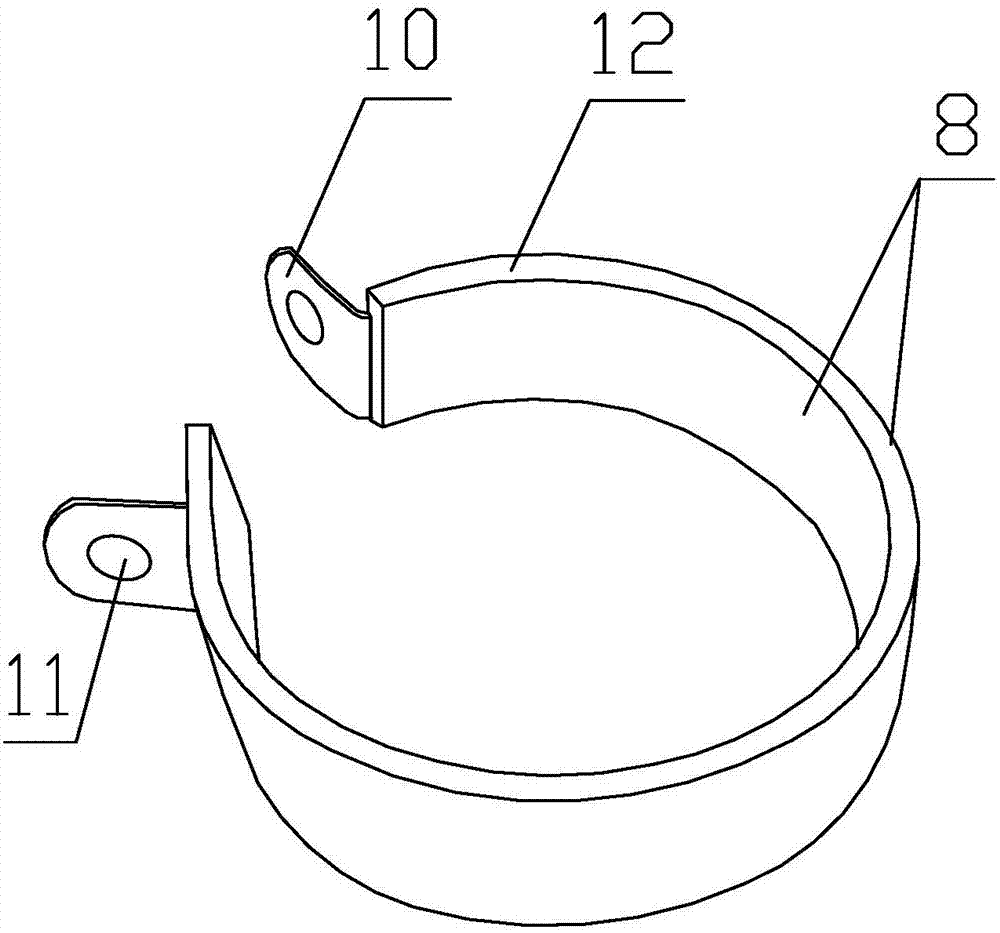

[0030] As a further improvement on the basis of Embodiment 1, a first rubber buffer pad 9 is provided in the fixing groove 7 .

Embodiment 3

[0032] Further improvement on the basis of Embodiment 2, the opening end of the fastening ring 8 is provided with a fixing plate 10, and the fixing plate 10 is provided with a through hole 11, and the bolts pass through the two fixing plates 10 of the fastening ring 8 in sequence Through holes and fastening with nuts to realize the installation of the fastening ring 8. The fastening ring 8 is wrapped with a second rubber buffer pad 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com