Switchgear

A technology for switch cabinets and cabinets, which is applied in the direction of switchgear parts and power devices inside the switch. It can solve the problems of large starting load, increasing the starting load of the motor, and increasing the minimum power, and achieves the effect of improving oil pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

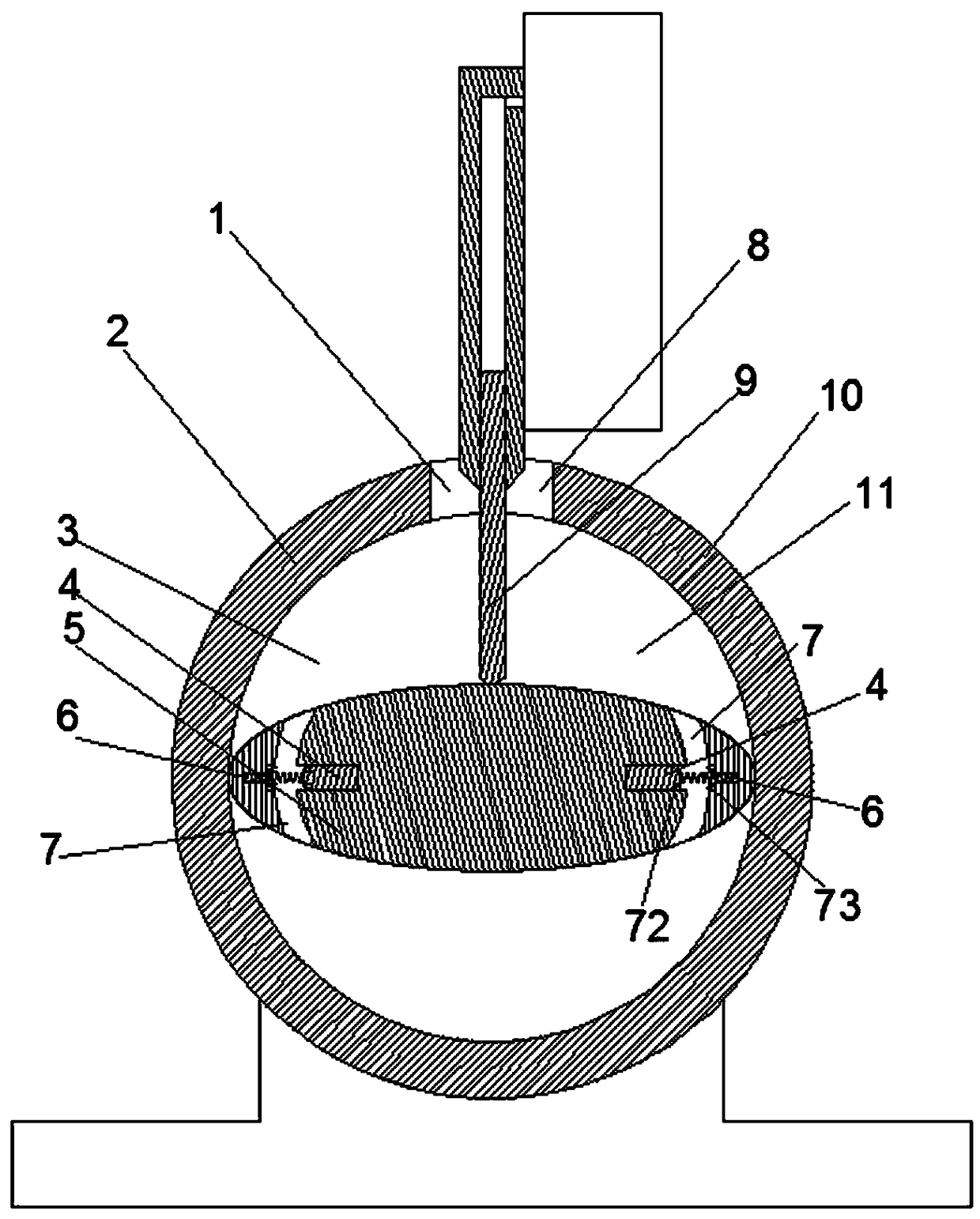

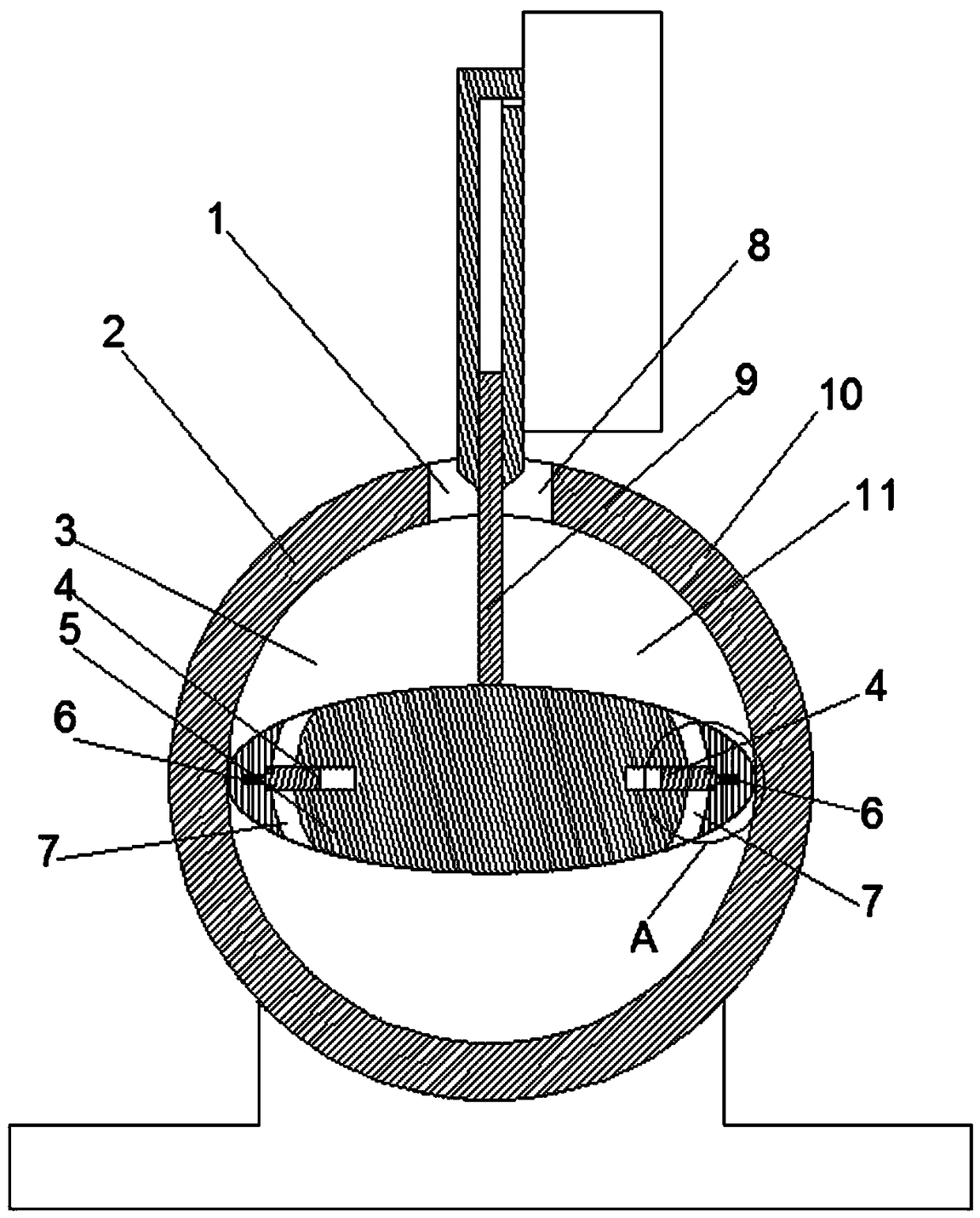

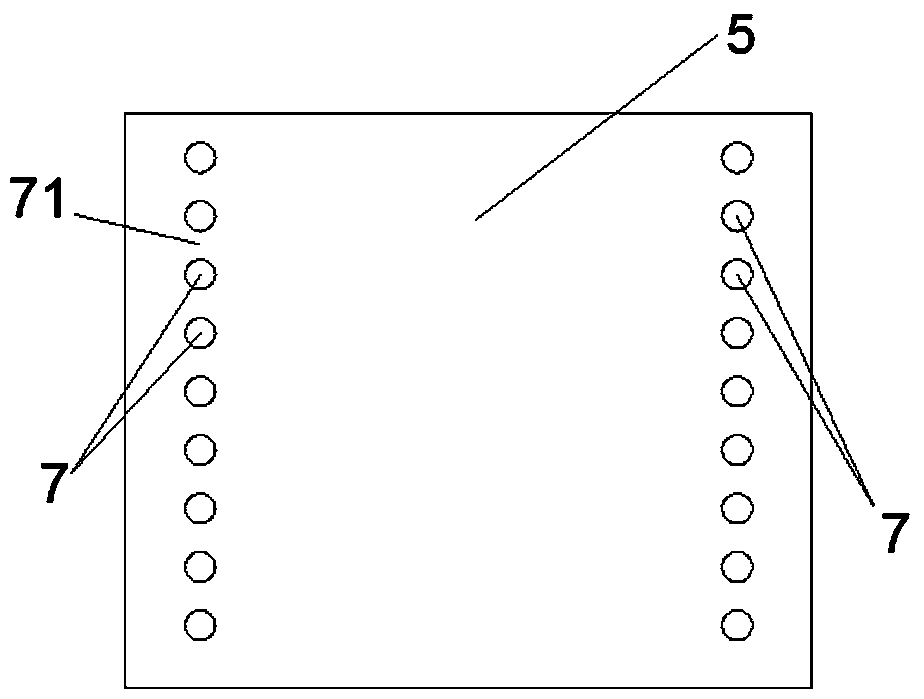

[0020] Examples of switchgear are Figure 1~9 Shown: The switchgear includes a cabinet body, and there are three single-phase units in the cabinet. Each single-phase unit includes a moving contact, a static contact, and a hydraulic operating mechanism that drives the moving contact. The hydraulic operating mechanism includes a power The power part includes a motor 37 and a pump 36, and the execution part includes a hydraulic cylinder and an energy storage spring. The basic working principle is that the power part can pump oil into the hydraulic cylinder, and the hydraulic cylinder compresses the energy storage spring to store energy. When closing is required, the energy storage spring releases energy, and the piston rod of the hydraulic cylinder drives the moving contact to move toward the static contact to realize the closing operation. The working mechanism of the hydraulic operating mechanism belongs to the prior art and will not be described in detail here. The improvement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com