Induction cooker

An induction cooker and electromagnetic coil technology, applied in the field of induction cookers, can solve problems such as poor heat dissipation effect, high temperature ignition of the induction cooker coil plate, and failure of the induction cooker to work normally, so as to achieve the effects of accelerating heat discharge, saving energy and increasing specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

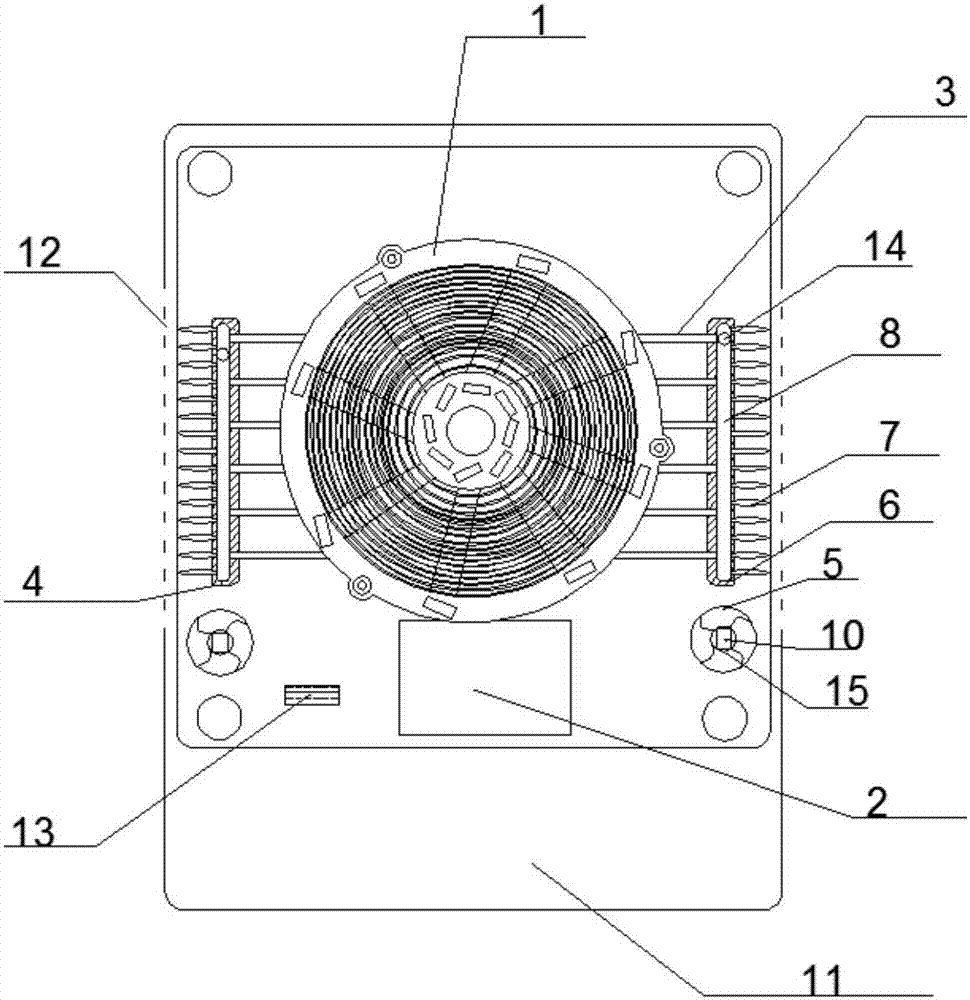

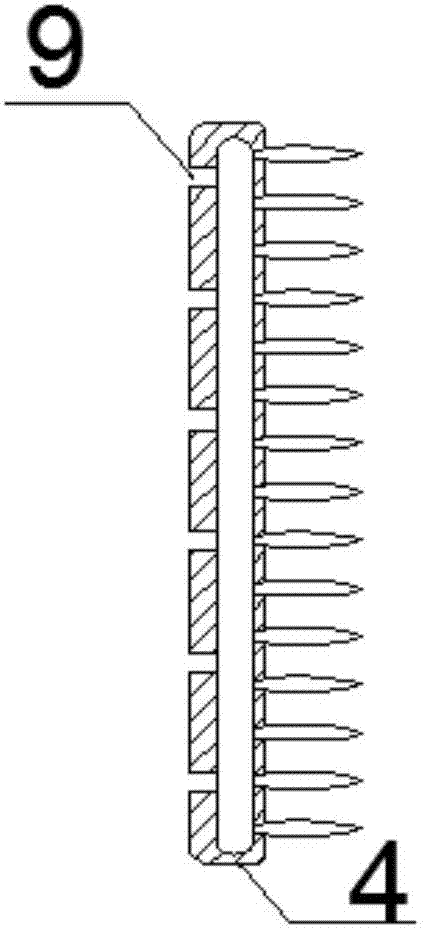

[0026] An induction cooker includes an electromagnetic coil pan assembly 1 and an induction cooker main control board assembly 2 arranged on one side of the electromagnetic coil pan assembly 1, and also includes a plurality of heat pipes 3, a heat dissipation assembly 4 and a heat dissipation fan 5, and the heat dissipation assembly 4 Symmetrically arranged on both sides of the electromagnetic coil disk assembly 1, the heat dissipation assembly 4 includes a heat dissipation base 6 and heat dissipation fins 7, a cavity 8 is provided inside the heat dissipation base 6, and heat dissipation fins are provided on the wall of the heat dissipation base 6 7. One end of the heat dissipation fin 7 communicates with the cavity 8, and the heat dissipation base 6 is provided with a plurality of grooves 9 at the position corresponding to the heat dissipation fin 7, and the heat pipe 3 is fixed in the groove 9, and the heat pipe 3 The other end is fixedly connected to the electromagnetic coil...

Embodiment 2

[0028] On the basis of Embodiment 1, it also includes an induction cooker bottom case 11, the induction cooker bottom case 11 is fixedly connected to the electromagnetic coil disk assembly 1, and the induction cooker bottom case 11 is provided with heat dissipation holes at positions corresponding to the heat dissipation fins 7 12. In this embodiment, the heat on the heat dissipation assembly 4 can be quickly transferred out through the heat dissipation holes 12 .

Embodiment 3

[0030] On the basis of Embodiment 1 or 2, an automatic controller 13 is arranged on the bottom shell 11 of the induction cooker; further, a temperature sensor 14 is arranged in the cavity 8 of the base; further, the heat dissipation The fan 5 is driven by a motor 10, and a speed reducer 15 is arranged on the cooling fan. In this embodiment, the rotating speed of the heat dissipation fan 5 can be automatically adjusted according to the temperature of the heat dissipation assembly 4, which not only accelerates the dissipation of heat, but also saves energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com