Valve core rotating device of control ball valve

A technology for controlling ball valves and rotating devices, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., which can solve the problems of insufficient pre-tightening force, large torque loss of power consumption, and poor sealing effect between valve seat and valve core and other issues, to achieve the effect of power consumption reduction, energy-saving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described and explained below in conjunction with accompanying drawing.

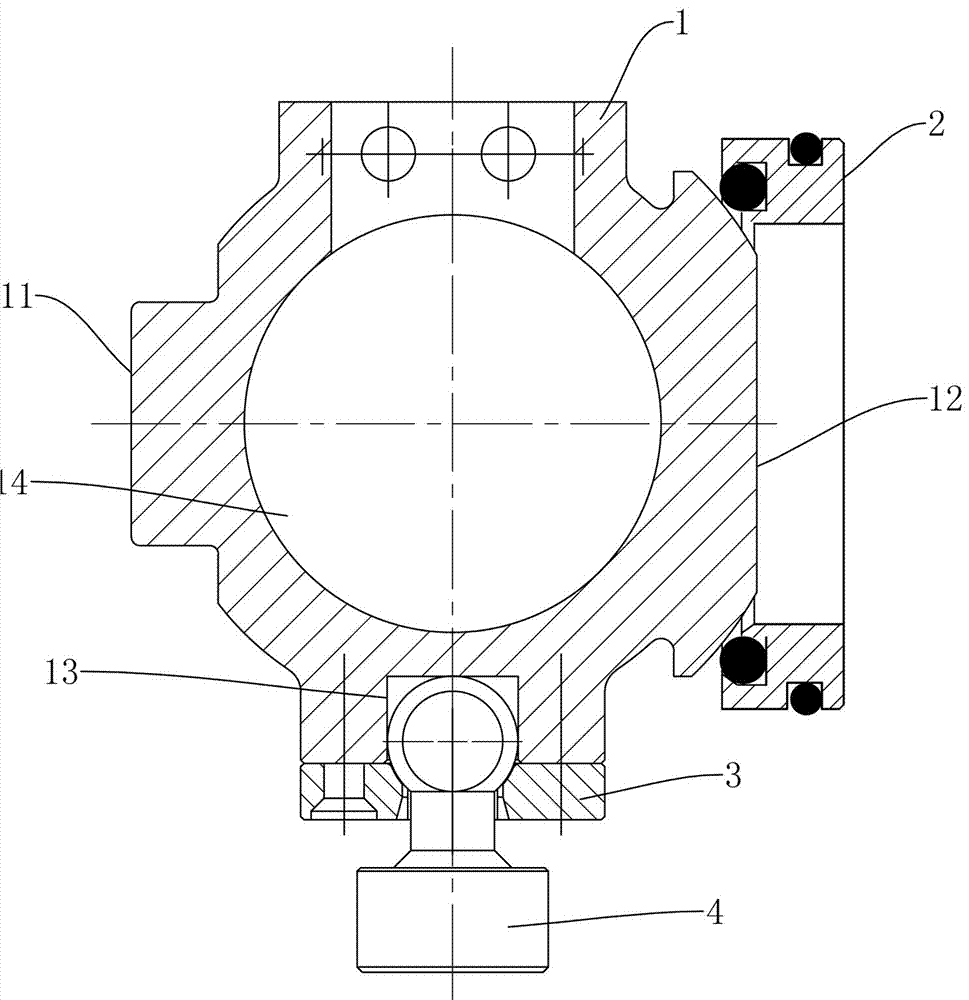

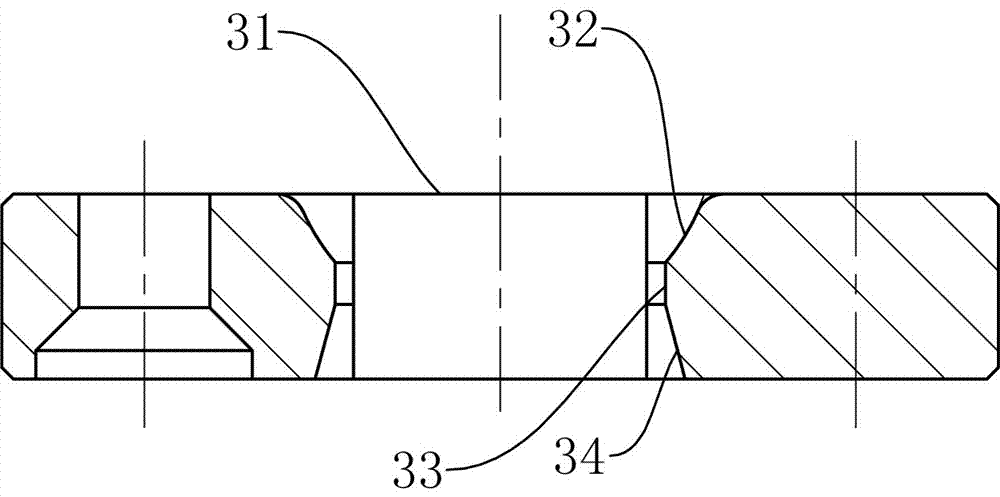

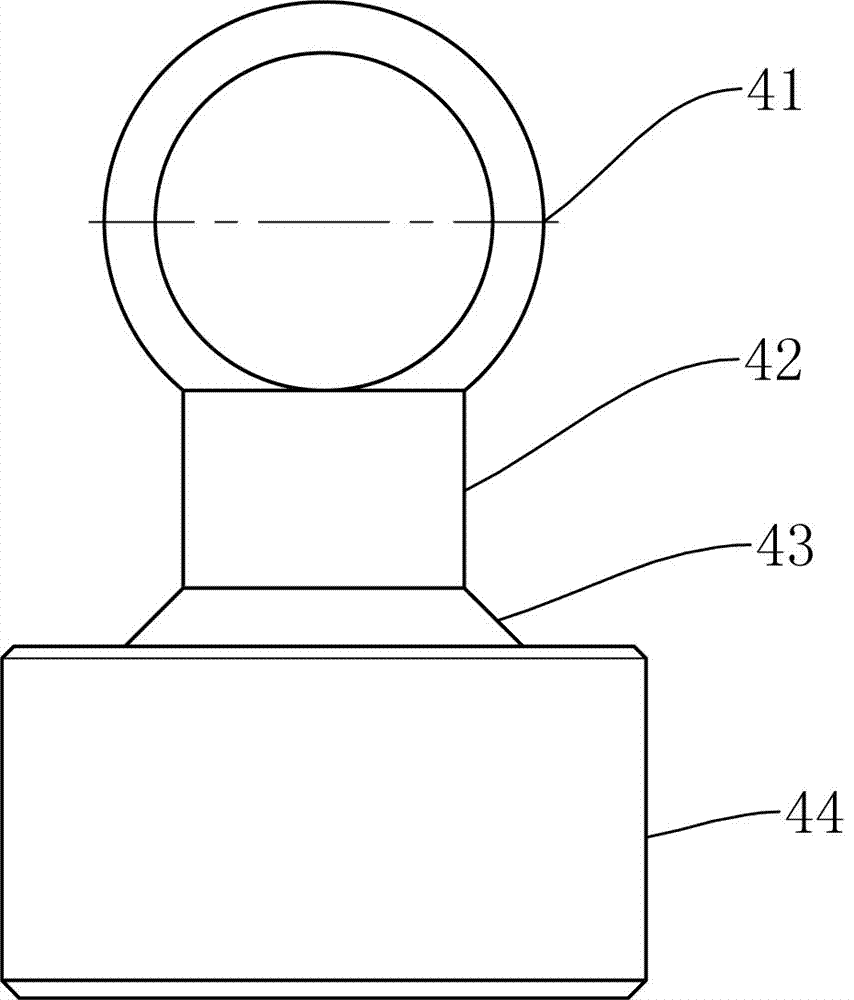

[0023] Such as Figure 1-4 The spool rotation device for controlling a ball valve includes a spool 1 and a spool lower bearing 4 supporting the rotation of the spool, an inner hole 13 is arranged at the bottom of the spool, and the bottom surface of the spool is fixedly connected to the spool chassis by screws 3. The central position of the spool chassis is provided with a central bearing hole 31 with a composite surface structure. Generally, there are two composite surfaces symmetrically arranged in the horizontal direction of the central position of the spool chassis. The lower bearing 4 of the spool and the The composite surface is more stable when it is rotated and contacted, and the central bearing hole 31 is flat and arranged in the vertical direction of the center of the valve core chassis. The lower bearing 4 of the spool includes a flat sphere 41, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com