Fluid separating device, shaft structure and method for producing petroleum or natural gas

A separation device and fluid technology, which is used in the production of fluids, earth-moving drilling, sealing/packing, etc., can solve the problems of slow downward speed and the inability of the fluid separation device to go down to the bottom of the well, so as to eliminate friction and reduce impact force. requirements, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

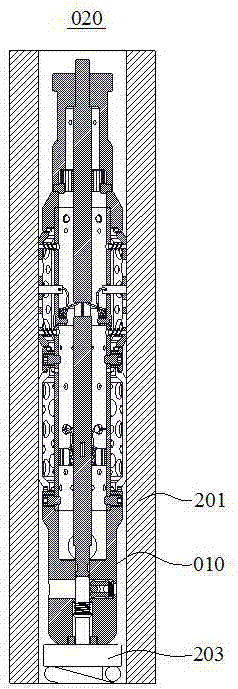

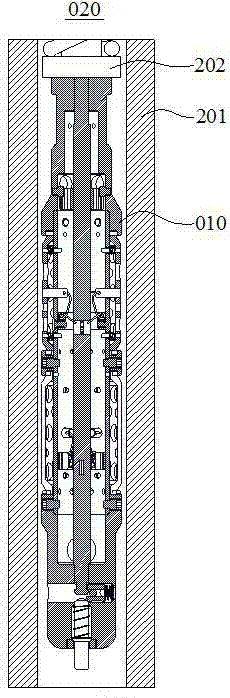

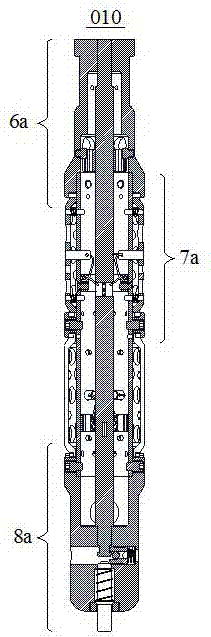

[0059] Please refer to figure 1 with figure 2 , figure 1 A working state diagram of the hoistway structure 020 provided in this embodiment, figure 2 Another working state diagram of the hoistway structure 020 provided in this embodiment. from figure 1 with figure 2 It can be seen from the figure that in this embodiment, the hoistway structure 020 includes a hoistway 201, and upper impact devices 202 ( figure 1 shown in ) and the lower impact device 203 ( figure 2 shown in ) and the fluid separation device 010 disposed in the hoistway 201. The fluid separation device 010 slides in the vertical direction in the hoistway 201 . When the fluid separation device 010 moves to the upper end of the shaft 201 , the fluid separation device 010 collides with the upper impact device 202 . When the fluid separation device 010 moves to the lower end of the shaft 201 , the fluid separation device 010 collides with the lower impact device 203 .

[0060] The fluid separation device...

Embodiment 2

[0077] This embodiment provides an oil or natural gas production method, which is realized based on the shaft structure 020 described in Embodiment 1. When the fluid separation device 010 is descending, the outlet of the shaft 201 is opened.

[0078] During the downward process of the fluid separation device provided in the related art, there is a relatively large frictional force between the partition and the inner wall of the shaft, and the upward flow of oil or natural gas under the fluid separation device exerts an upward thrust on the fluid separation device. Under the combined action of friction, upward thrust, and fluid resistance of oil or natural gas, the fluid separation device goes down slowly, or even cannot go down at all. In order to make the fast fluid separation device go down or speed up the downward speed of the fluid separation device, in the related art, when the fluid separation device is going down, it is necessary to close the outlet of the well to balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com